Surface treatment process and treatment device of environment-friendly paperboard raw material for self-Hi pot

A surface treatment device and surface treatment technology, which are applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. Difficulty in coating and other problems, to achieve the effect of preventing weak fixation and convenient coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A surface treatment process for environmentally friendly cardboard raw materials for self-healing pots, comprising the following steps:

[0050] S1, coating configuration:

[0051] 1) get a certain amount of acrylic resin and mix with methyl-etherified amino resin, wherein, the volume ratio of acrylic resin and methyl-etherified amino resin is 4:1;

[0052] 2) Add a trace amount of precipitated barium sulfate, EFKA-4560 dispersant and EFKA-2526 defoamer to the mixed solution, and stir to fully mix to obtain a mixed emulsion;

[0053] 3) take the mixed emulsion obtained in step 2), add a certain amount of water to dilute, wherein, the proportion of styrene-acrylic emulsion is 30%-40%, the proportion of water is 60%-70%, and the acrylic paint is made;

[0054] S2, the inner coating of the lower bracket:

[0055] 1) Take a certain amount of acrylic paint, use a spray gun or a brush, apply the acrylic paint evenly on the inner wall of the lower bracket, and evenly apply t...

Embodiment 2

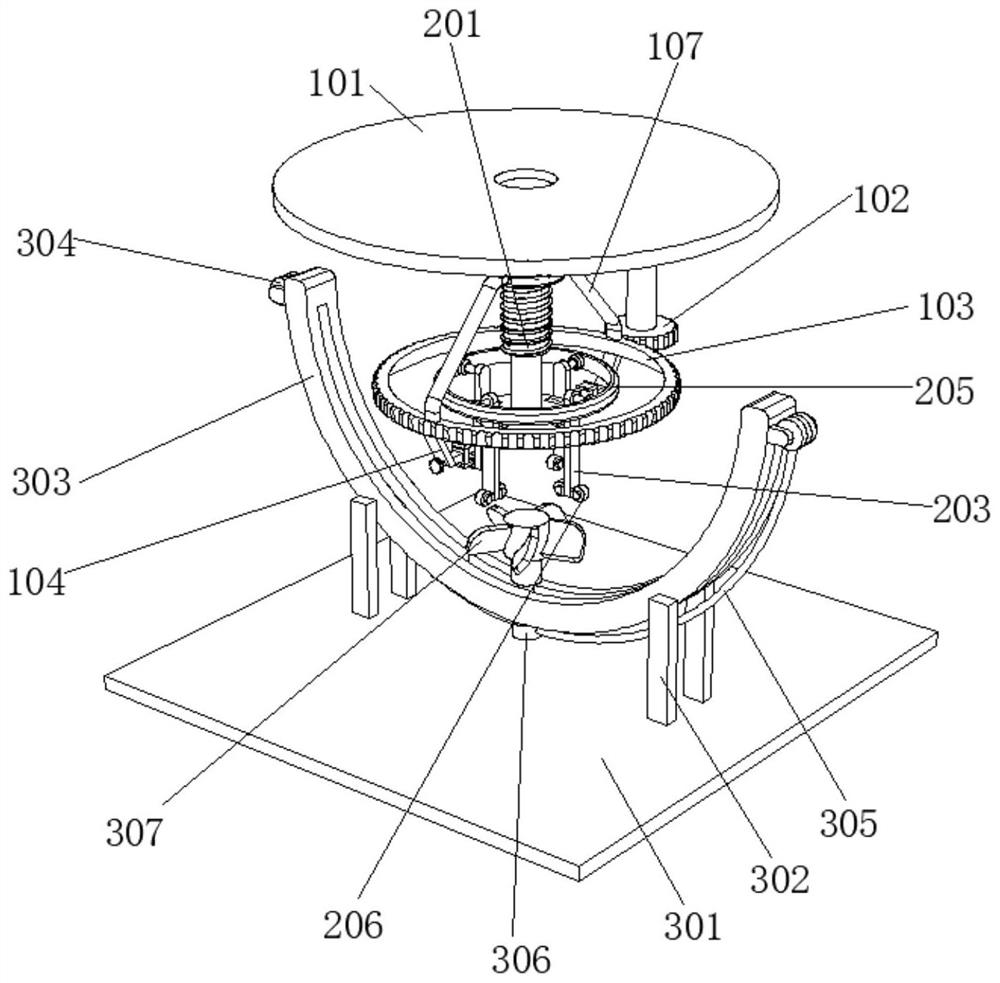

[0066] see Figure 1 to Figure 5 , a surface treatment device for environmentally friendly cardboard raw materials for self-healing pots, including a top plate 101, the top plate 101 is connected with a transmission wheel 102, and is slidably connected with a connecting rod 109, and the top plate 101 defines the position of the connecting rod 109 and the transmission wheel 102; A transmission wheel 102 is arranged below the 101. One end of the transmission wheel 102 is hinged with the top plate 101, and the other end is meshed with the driven wheel 103. The size is adapted to the driven wheel 103. The first motor starts to move, and then drives the driven wheel 103 to start to move;

[0067] A driven wheel 103 is engaged with the outside of the transmission wheel 102, and the size of the driven wheel 103 is adapted to the transmission wheel 102. The driven wheel 103 starts to move under the driving of the transmission wheel 102, thereby driving the positioning member 104, the ...

Embodiment 3

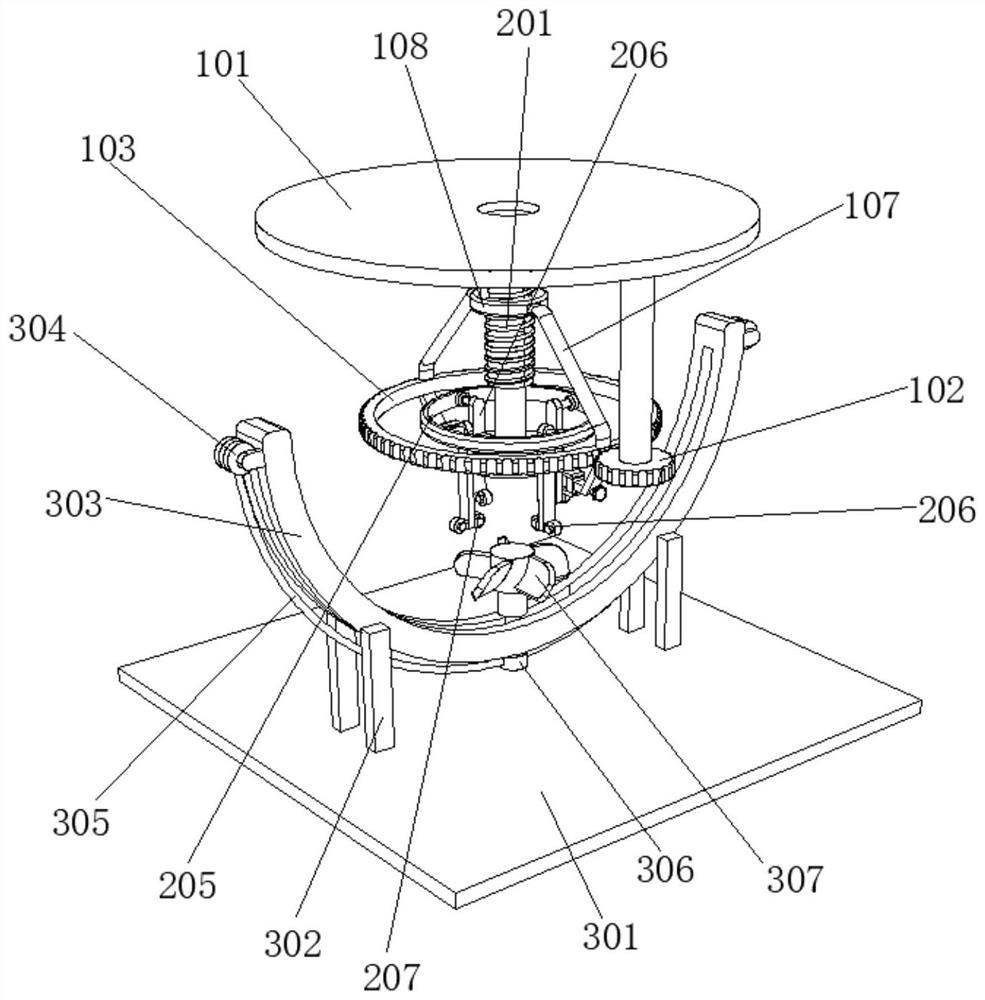

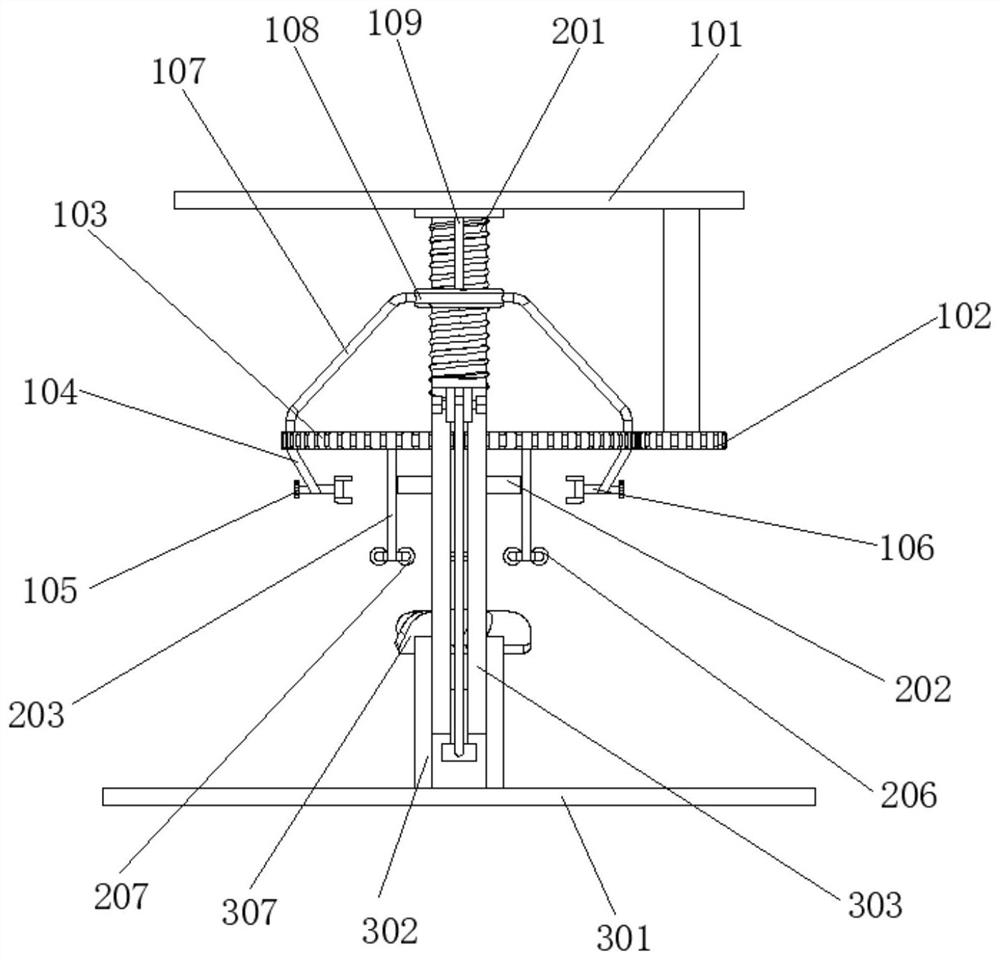

[0071] see Figures 6 to 8 , a surface treatment device for environmentally friendly cardboard raw materials for self-healing pots, including a screw 201, a limit ring 108 is sleeved outside the screw 201, the bottom of the screw 201 is fixedly connected with a limit block 202, and the screw 201 defines the limit block 202. At the same time, the screw 201 will start to rise under the driving of the limit ring 108, and then drive the limit block 202 to rise; the limit block 202 is fixedly connected below the screw 201, the limit block 202 is hinged with the connecting rod 203, and the limit block 202 defines The position of the connecting rod 203 is determined, and at the same time, the limit block 202 starts to rise under the driving of the screw 201, thereby driving the connecting rod 203 to rise;

[0072] A connecting rod 203 is arranged on the outer side of the limit block 202 , the connecting rod 203 is arranged around the periphery of the limit block 202 , a through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com