Asphalt paver for municipal road and construction process

A municipal road and paver technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of uneven asphalt spreading, inability to adjust the width of the paving, and inconvenient heights, and achieve the effect of avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

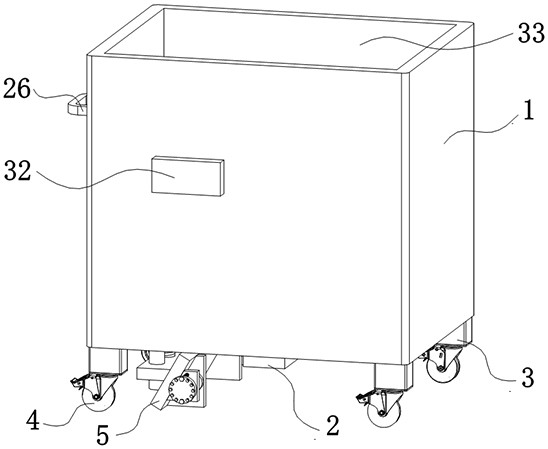

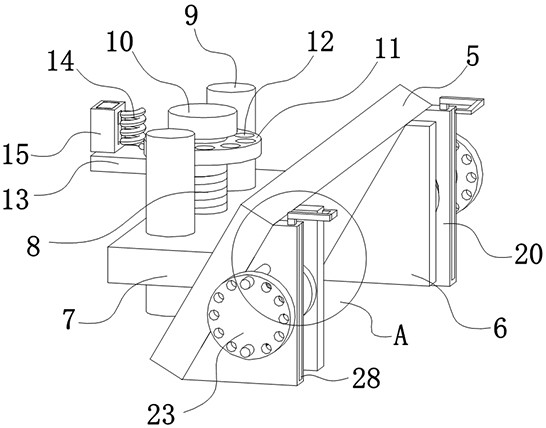

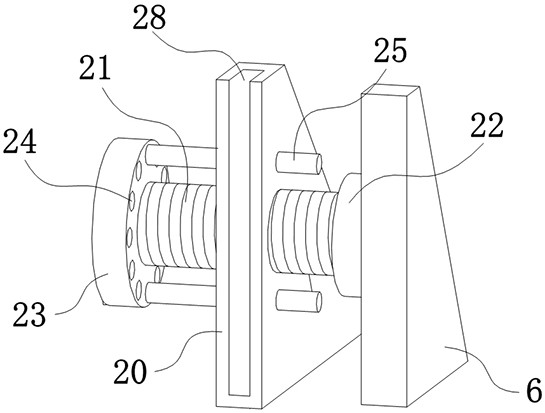

[0040] Depend on Figure 1 to Figure 4 Given, the present invention includes a body 1, one side of the body 1 is provided with a controller 32, the controller 32 electrically controls each electrical component, the interior of the body 1 is provided with a hopper 33, the bottom of the hopper 33 passes through the body 1 and passes through the electromagnetic The valve is provided with a blanking pipe 2. The solenoid valve can control the opening size of the blanking pipe 2. The asphalt inside the hopper 33 can be directly dropped to the ground along the blanking pipe 2 for subsequent paving work. The bottom of the body 1 is provided with several Fixed block 3, the bottom of the fixed block 3 is provided with a universal wheel 4, the lower part of the body 1 is provided with a scraper 5, and both sides of the scraper 5 are slidably connected with a side baffle 6, and the side baffle 6 and the scraper 5 pass through The adjustment component is connected, and the side baffle 6 ca...

no. 2 example

[0051] like Figure 5-7 It can be seen from the first embodiment that, in actual operation, when the hot-melt asphalt in the hopper 33 falls to the ground along the drop tube 2, the volume of the asphalt will decrease due to the principle of thermal expansion and contraction, and further in the spread Paving will cause unevenness of the road surface, and even cause the road surface to crack. At the same time, after a long time of use, the surface of the scraper 5 and the side baffle 6 will adhere to part of the asphalt, which will hinder the subsequent paving work. In order to solve the above problems, improve the degree of thermal expansion and contraction of asphalt under different environmental adjustment, and then ensure the smoothness of pavement paving, and scrape off the asphalt adhering to the surface of the scraper 5 and the side baffle 6 after the paving is completed. , The asphalt paver for municipal roads also includes: a first temperature sensor is arranged inside...

no. 3 example

[0066] like Figure 8 As shown, a construction process of an asphalt paver for municipal roads, the construction process involving an asphalt paver for municipal roads, includes the following steps:

[0067] S1. Move the body 1 to a suitable position, the molten asphalt is placed inside the hopper 33, the controller 32 controls the solenoid valve in the blanking pipe 2 to open, and the asphalt in the hopper 33 falls to the ground along the blanking pipe 2, and the first temperature The sensor detects the temperature value in the blanking tube 2;

[0068] S2. The controller 32 controls the first motor 10 to start, the first motor 10 drives the first threaded column 8 to rotate, the first threaded column 8 rotates to drive the first fixed plate 7 to move upward, and the first fixed plate 7 drives the scraper when moving upward. 5 Move up to adjust the asphalt paving height;

[0069] S3. According to the opening degree of the solenoid valve and the rising height of the scraper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com