Self-adaptive steel support adjusting system for deep foundation pit

A technology of adjustment system and steel support, applied in the direction of basic structure engineering, basic structure testing, construction, etc., can solve the problems of inability to adjust, cannot be reused, cannot be adjusted, etc., to achieve high reuse rate, material saving, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

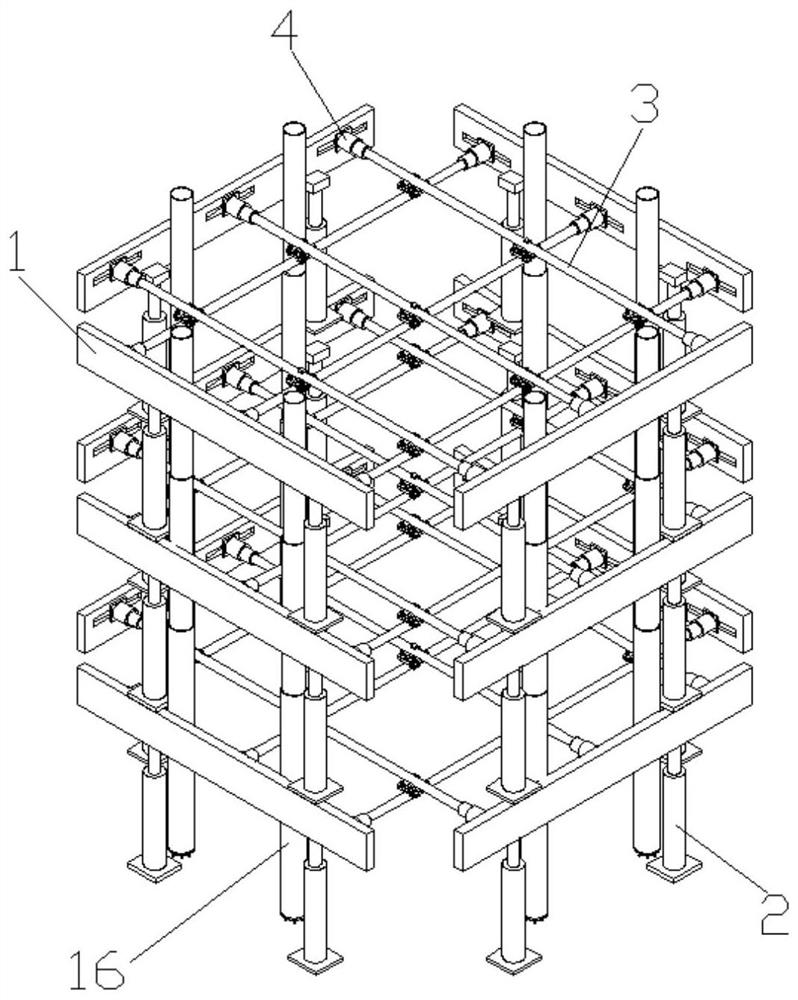

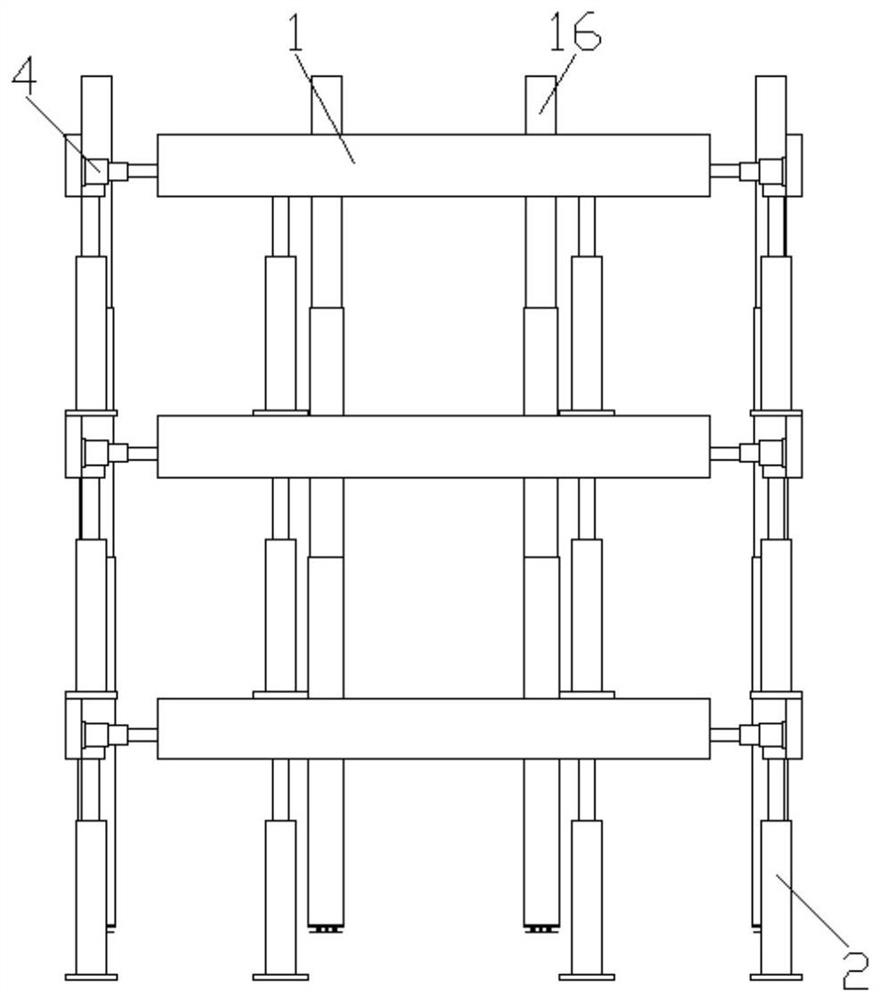

[0034] like Figure 1-10 As shown in the figure, a deep foundation pit self-adaptive steel support adjustment system in this embodiment includes a plurality of support structures connected vertically in sequence, and the support structures include a purlin assembly, a pile body assembly, a steel support assembly and a detection assembly ;

[0035] The purlin assembly includes four baffles 1, and the four baffles 1 are respectively located on the front side, the rear side, the left side and the right side of the steel support assembly;

[0036] The pile assembly includes a plurality of pile units, and the pile units correspond to the baffles 1 one-to-one. The pile unit includes a plurality of first hydraulic cylinders 2, and the pistons of the first hydraulic cylinders 2 are vertical. Arrangement, in the two adjacent baffles 1 up and down, the baffle 1 located above is fixedly connected to the piston of the first hydraulic cylinder 2, and the baffle 1 located below is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com