TFT (Thin Film Transistor) array substrate structure for improving metal residues on side surface of Tapper and manufacturing method of TFT array substrate structure

An array substrate structure and metal residue technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to improve product yield and avoid metal residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

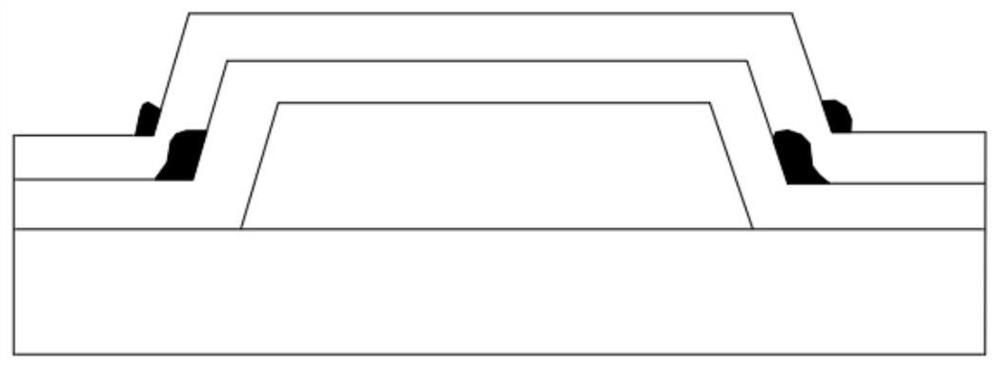

[0040] like figure 1 As shown in the figure, a TFT array substrate structure for improving the metal residue on the side of the Taper comprises a TFT side glass substrate 1, and the glass substrate 1 is provided with a GE metal layer 2 / inorganic film layer 3 mixed barrier layer, an inorganic film layer 3 and The upper surface of the GE metal layer 2 is flush, the inorganic film layer 3 is arranged on both sides of the GE metal layer 2, the acute angle between the inclined plane of the inorganic film layer 3 and the glass substrate 1 is less than 50°, and the GE metal layer 2 / inorganic A GI insulating layer 4 is provided on the hybrid barrier layer of the film layer 3 , and a PV insulating layer 5 is provided on the GI insulating layer 4 .

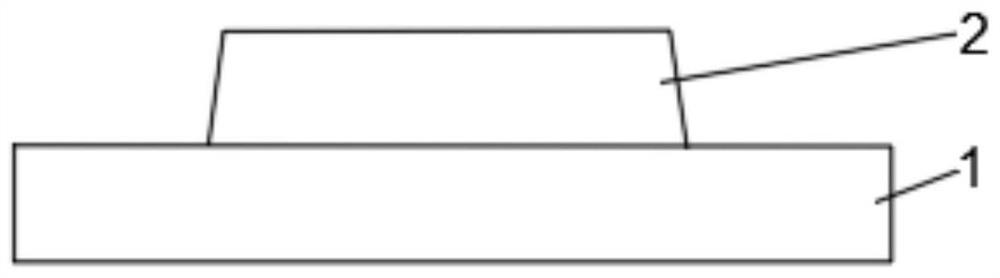

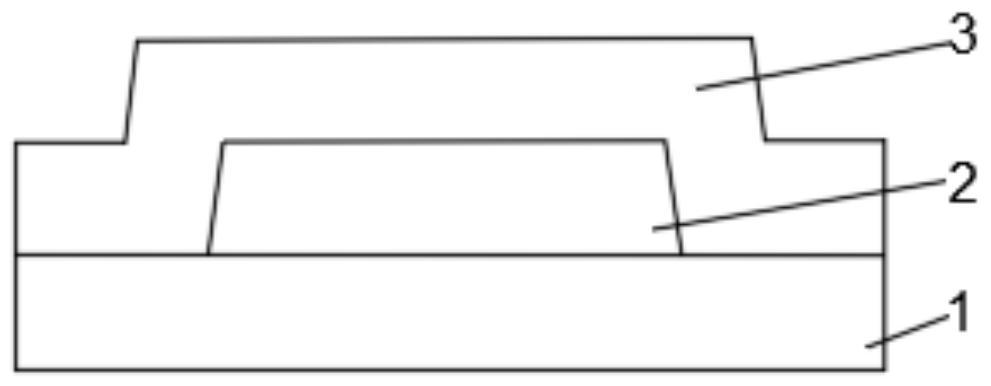

[0041] like Figure 2-11 As shown in one of the drawings, a method for manufacturing a TFT array substrate structure with improved metal residues on the side of the Taper includes the following steps:

[0042] 1) A GE metal layer 2 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com