Micro-ring resonator with cavity structure

A ring resonator and ring resonator technology, applied in the field of resonators, can solve the problems of limiting the quality factor of the resonant system to increase, and achieve the effects of improving energy utilization efficiency, reducing thermoelastic energy loss, and reducing the peak value of thermoelastic damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

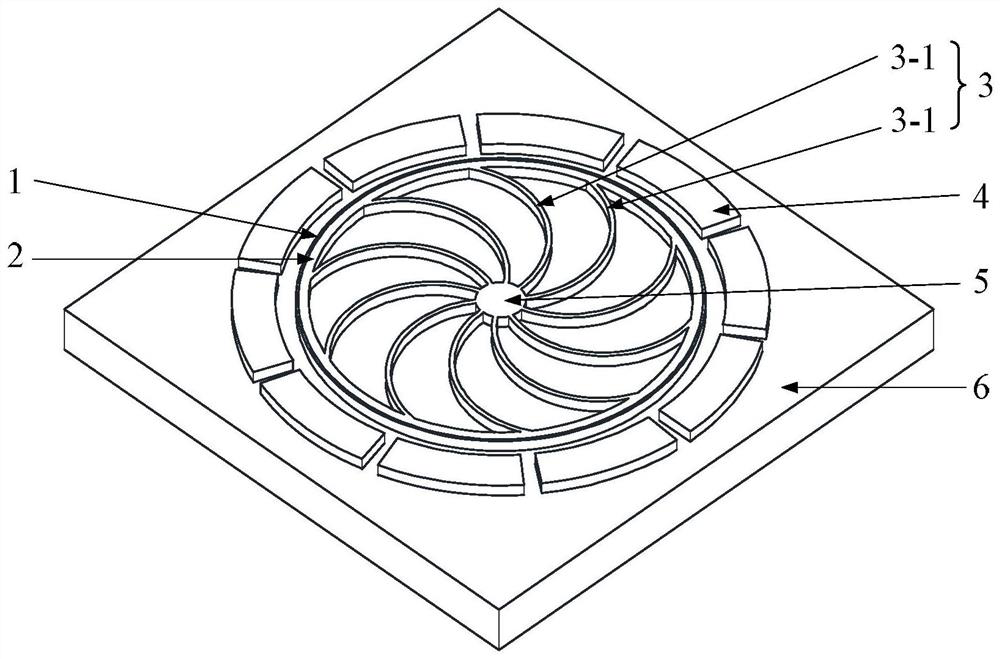

[0040] see figure 1 and figure 2 Illustrating this embodiment, the micro-ring resonator with a cavity structure described in this embodiment includes a ring resonator 2 on a base 6, a support structure 3, a driving electrode 4 and an anchor point 5, and the circular The outer surface of the ring oscillator 2 is plated with a metal conductive layer 1;

[0041] The inner surface of the ring resonator 2 is fixedly connected with the anchor point pile 5 through the support structure 3, and the three are coaxial;

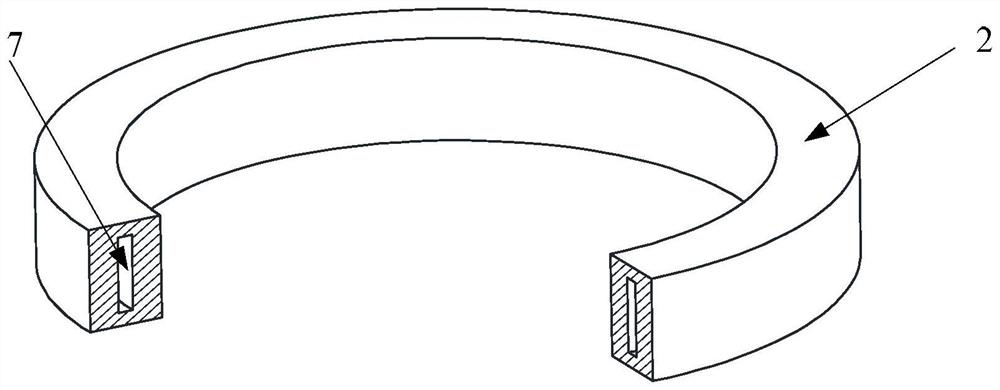

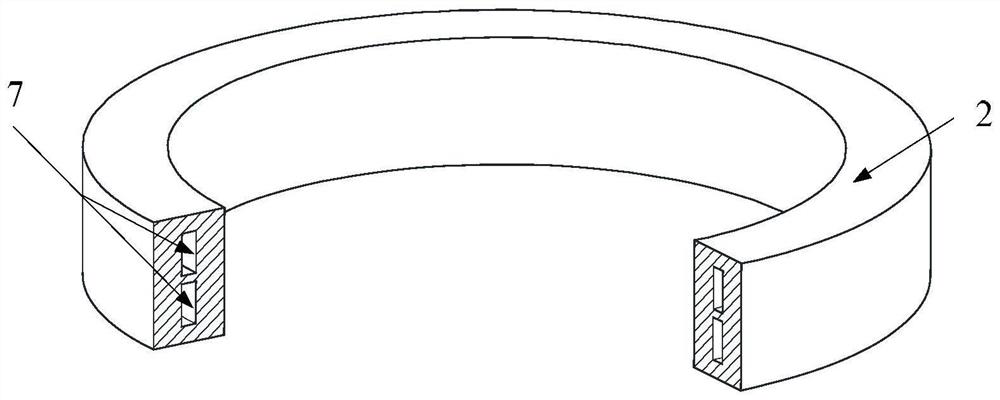

[0042] A cavity 7 is provided along the annular extending direction of the annular resonator 2, and the cavity 7 is located in the annular body of the annular resonator 2;

[0043] A plurality of driving electrodes 4 are evenly distributed on the outer side of the ring resonator 2 in a ring shape at equal intervals, and the driving electrodes 4 are used to drive the ring resonator 2 to work at the natural frequency.

[0044] In this embodiment, the ring resonator 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com