Delicious freeze-dried instant noodles and preparation method thereof

A technology of instant noodles and freeze-drying, which is applied in the field of delicious freeze-dried instant noodles and its preparation, which can solve the problems of stabbing the tongue, not being caught by the public, and bad taste, and achieves the effect of smooth taste and reduced mixed taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

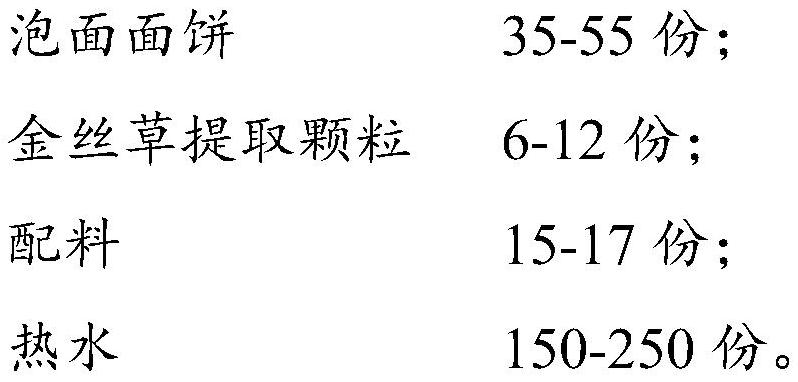

[0025] A preparation method of delicious freeze-dried instant noodles, the method comprises the following steps:

[0026] S1, pick and remove the impurities and foreign bodies in the goldenseal, then wash with water, and dry the washed goldenseal to obtain goldensweed hay;

[0027] S2. Add the golden grass hay to 35 times of water by weight, soak for 35min; then heat to boiling, decoct for 75min, filter; add 30 times of water, heat to boiling, decoct for 75min, filter; The two decoction liquids were combined, and then concentrated to 1.5 times the weight of the above-mentioned golden grass hay to obtain the golden grass extract paste;

[0028] S3, make the extract paste of goldenrod grass into wet granules with a thickness of 1.5cm, and pass through a 10-mesh sieve;

[0029] S4, drying the wet granules in an environment of 55°C, and turning them when the moisture content of the wet granules drops to 10%, until the moisture content does not exceed 4%, to obtain the extract gra...

Embodiment 2

[0033] A preparation method of delicious freeze-dried instant noodles, the method comprises the following steps:

[0034] S1, pick and remove the impurities and foreign bodies in the goldenseal, then wash with water, and dry the washed goldenseal to obtain goldensweed hay;

[0035] S2. Add the golden grass hay to 35 times of water by weight, soak for 35min; then heat to boiling, decoct for 75min, filter; add 30 times of water, heat to boiling, decoct for 75min, filter; The two decoction liquids were combined, and then concentrated to 1.5 times the weight of the above-mentioned golden grass hay to obtain the golden grass extract paste;

[0036] S3, make the extract paste of goldenspores into wet granules with a thickness of 1.5cm, and pass through a 10-mesh sieve;

[0037] S4, drying the wet granules in an environment of 55°C, and turning them when the moisture content of the wet granules drops to 10%, until the moisture content does not exceed 4%, to obtain the extract granul...

Embodiment 3

[0041] A preparation method of delicious freeze-dried instant noodles, the method comprises the following steps:

[0042] S1, pick and remove the impurities and foreign bodies in the goldenseal, then wash with water, and dry the washed goldenseal to obtain goldensweed hay;

[0043] S2. Add the golden grass hay to 35 times of water by weight, soak for 35min; then heat to boiling, decoct for 75min, filter; add 30 times of water, heat to boiling, decoct for 75min, filter; The two decoction liquids were combined, and then concentrated to 1.5 times the weight of the above-mentioned golden grass hay to obtain the golden grass extract paste;

[0044] S3, make the extract paste of goldenspores into wet granules with a thickness of 1.5cm, and pass through a 10-mesh sieve;

[0045] S4, drying the wet granules in an environment of 55°C, and turning them when the moisture content of the wet granules drops to 10%, until the moisture content does not exceed 4%, to obtain the extract granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com