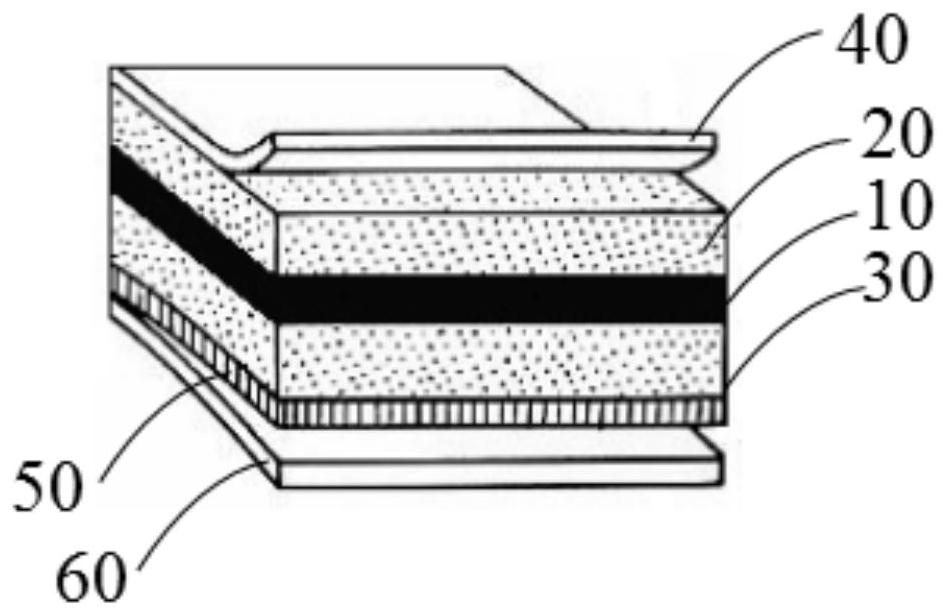

Preparation method of ultra-wide polarizing film and polarizing plate

A technology of polarizing film and polarizing plate, which is applied in polarizing elements, optical elements, household appliances, etc. It can solve the problems of affecting optical characteristics, uneven force, and PVA film breakage, so as to improve uniformity and stability and ensure the film surface Flatness, the effect of improving the level of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In order to solve the above problems, the present invention provides a method for preparing an ultra-wide polarizing film, comprising the following steps:

[0038] 1) Provide polyvinyl alcohol PVA film;

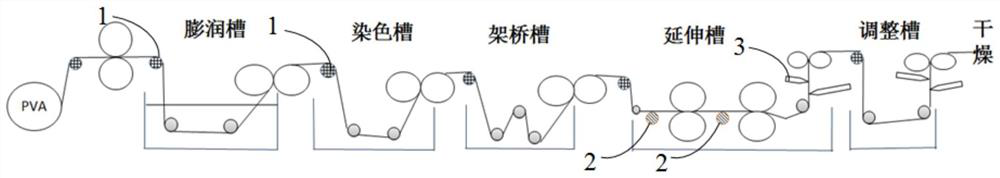

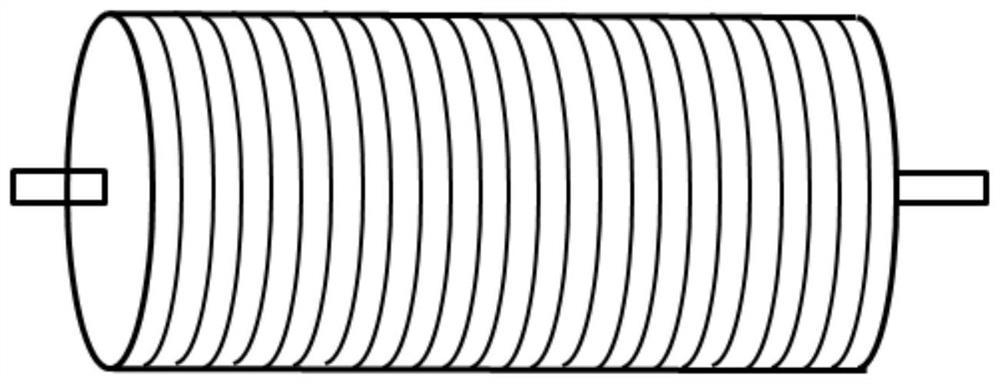

[0039] 2) at the entrance of swelling groove, dyeing groove, bridging groove, extension groove and adjustment groove, thread-shaped unfolding wheel 1 is all provided, and after described polyvinyl alcohol PVA film is evenly unfolded by described threaded-shaped unfolding wheel 1, Enter the swelling tank, the dyeing tank, the bridging tank, the extension tank and the adjustment tank in sequence, and stretch to 5-7 times longitudinally;

[0040] 3) drying the longitudinally stretched polyvinyl alcohol PVA film in an oven to adjust the moisture content to 10-20% to obtain a polarizing film with a width of 2.2-2.6 m.

[0041] In order to prepare an ultra-wide polarizing plate, the present invention adopts a polyvinyl alcohol PVA film with a width of 4500 mm to 6500 mm and...

Embodiment 1

[0060] (1) A polyvinyl alcohol PVA film with a width of 6000 mm and a thickness of 45 μm was used.

[0061] (2) A set of screw-shaped unfolding wheels are arranged at the entrance of each groove in the polarizing film manufacturing process.

[0062] (3) Swelling stage: the polyvinyl alcohol PVA film is expanded into the swelling tank after being expanded by the above-mentioned threaded unrolling wheel, the groove length of the swelling tank is 20m, the width of the roller is 8000mm, and the polyvinyl alcohol PVA film is in the swelling tank, In contact with water at 40°C, the residence time is 2 to 4 minutes, and the absorption axis direction extends 2 to 3 times;

[0063] (4) Dyeing stage: The polyvinyl alcohol PVA film is fully spread out by the above-mentioned thread unrolling wheel and then enters the dyeing tank to ensure uniform dyeing. The tank length of the dyeing tank is 10m, the width of the roller is 8000mm, and the chemical solution of the dyeing tank is a mixed s...

Embodiment 2

[0071] The difference from Example 1 is that the polarizing film drying oven is provided with 3 sections, and the temperature is stepped up and dried, and the temperatures are 60°C, 70°C, and 80°C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com