Composite tension control system

A tension control and composite technology, which is applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of product performance fluctuation, unsatisfactory product rate, tension control imbalance, etc., to achieve uniform force, The effect of saving fiber consumption and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

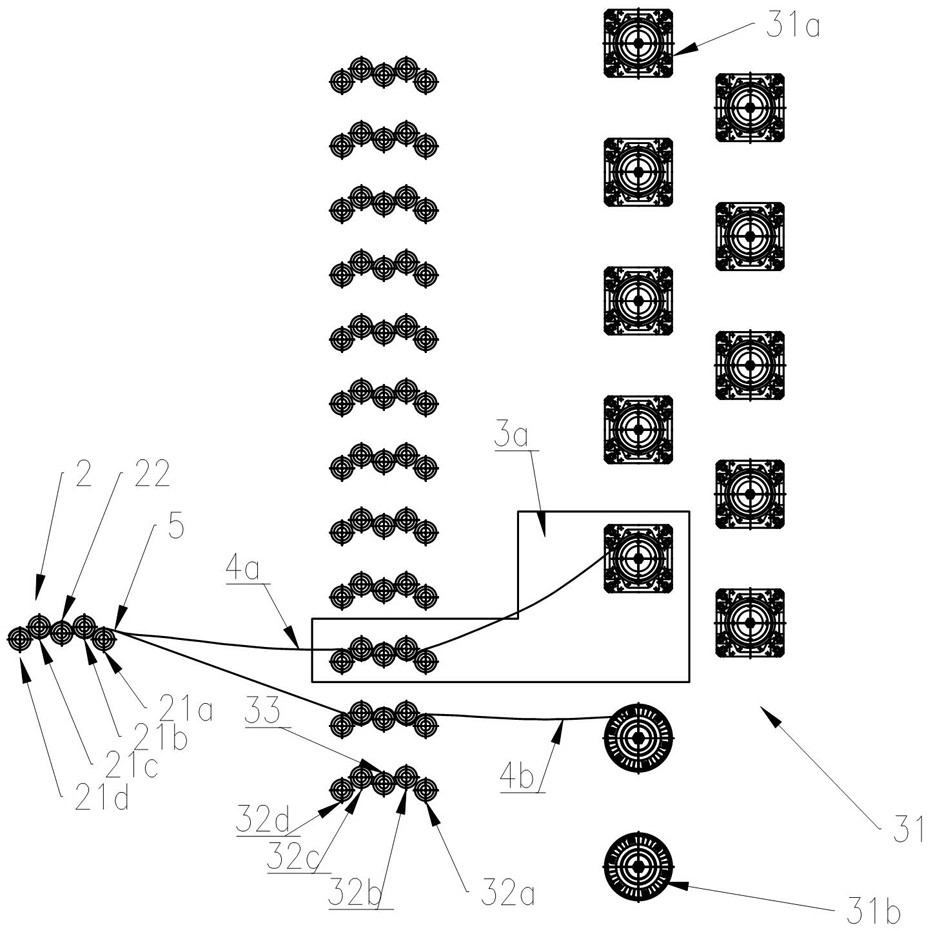

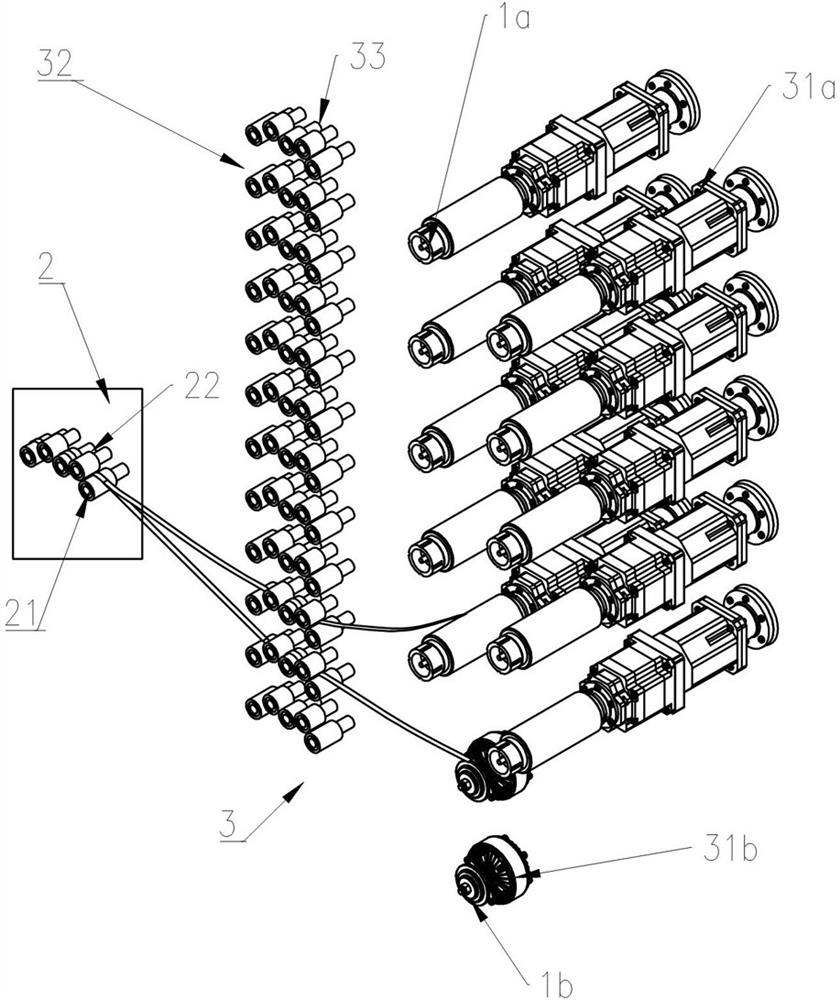

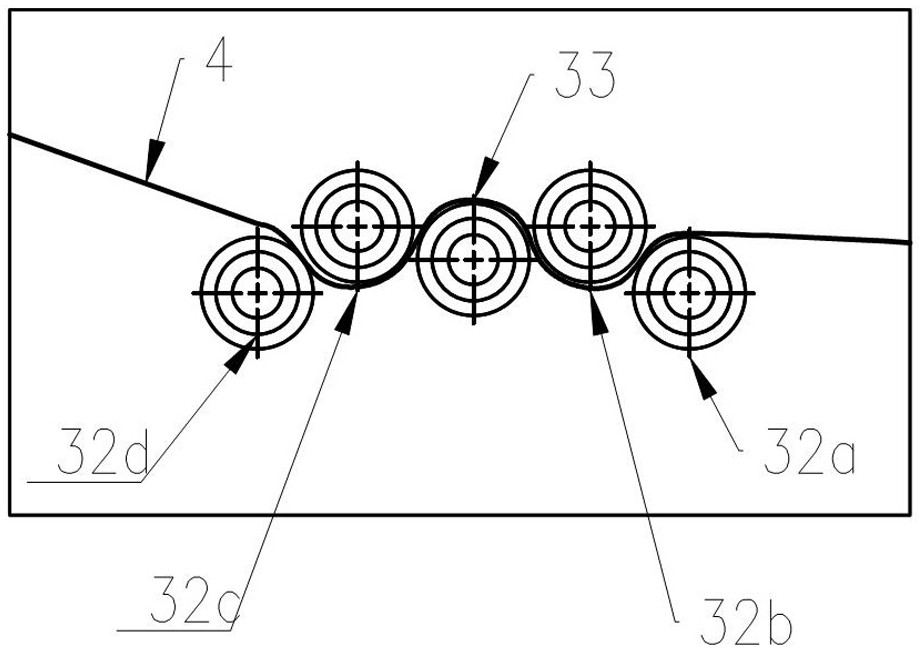

[0016] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, so as to make the technical solutions of the present invention easier to understand and grasp, so as to make a clearer definition of the protection scope of the present invention.

[0017] Aiming at the disadvantages of the existing winding machine in the forming process, such as the poor balance control of the yarn group and its yarn tension, and the low forming yield rate, the designer of the present invention innovatively proposes a composite tensioning device relying on the experience in the maintenance of the production line equipment. The control system is suitable for transforming various winding equipments currently put into production, and realizes the independent adjustment of the tension of the single yarn and the balanced control of the tension between the yarn groups.

[0018] In order to solve the above technical problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com