Rare earth-iron-based alloy material and preparation method and application thereof

A technology of iron-based alloys and alloy materials, which is applied in the field of rare earth-iron-based alloy materials and their preparation and application, can solve the problems of attenuation of hydrogen absorption capacity and low hydrogen absorption capacity, and achieve improved phase structure, good reversible performance, and effective The effect of high hydrogen absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of the alloy material of the present invention includes: (1) a forming step of a solid alloy; and (2) a heat treatment step. A detailed description is given below.

[0063] First, the formation steps of the solid alloy are described. will form Y satisfying Eq. (1) a R1 b R2 c Fe d Mn e The raw materials are placed in a smelting device for smelting to obtain a smelting product; the smelting product is made into a solid alloy. formula Y a R1 b R2 c Fe d Mn e The various elements and their molar coefficients are as described above and will not be repeated here.

[0064] The smelting apparatus of the present invention may comprise a vacuum induction furnace. The preparation method of the present invention may include a vacuuming step and an inert gas filling step. The smelting device was evacuated to an absolute vacuum degree below 3Pa. Preferably, the smelting device is evacuated to an absolute vacuum degree below 2Pa. More preferably,...

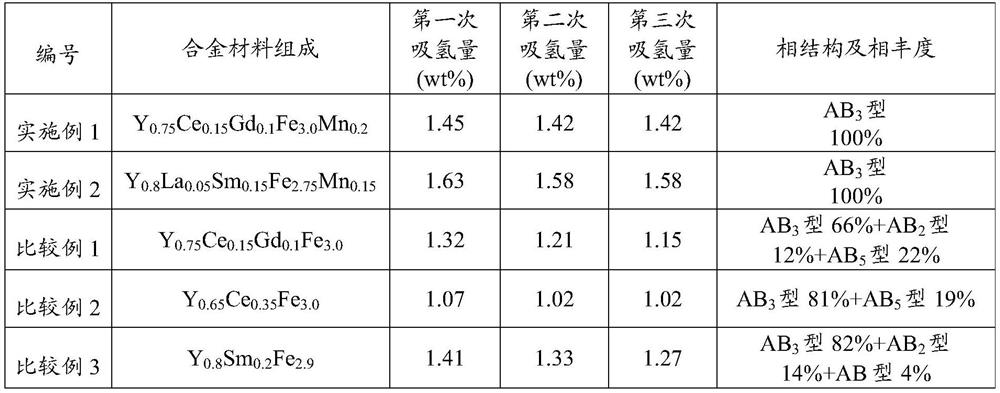

Embodiment 1 and comparative example 1~2

[0075] According to the formula in Table 1, prepare the rare earth-iron-based alloy material as follows:

[0076] According to the melting point of the raw materials, they are put into the crucible in order, and the rare earth metal is located in the uppermost layer of the raw materials. The crucible is placed in a vacuum induction furnace; then the vacuum induction furnace is evacuated to an absolute vacuum of less than 1Pa, and filled with argon to a relative vacuum of -550Pa. Set the power of the vacuum induction furnace to 7kW and keep it for 5min, then adjust the power of the vacuum induction furnace to 15kW and keep it for 5min until all the alloys form alloy liquid. Reduce the power of the vacuum induction furnace to 0kW, and then adjust the power of the vacuum induction furnace to 12kW after the alloy liquid surface forms a protective film. After the alloy protective film is opened and the alloy liquid surface is exposed, the alloy liquid is cast into a water-cooled co...

Embodiment 2 and comparative example 3

[0080] According to the formula in Table 1, the rare earth-iron-based alloy material was prepared as follows:

[0081] According to the melting point of the raw materials, they are put into the crucible in order, and the rare earth metal is located in the uppermost layer of the raw materials. The crucible is placed in a vacuum induction furnace; then the vacuum induction furnace is evacuated to an absolute vacuum of less than 1Pa, and filled with argon to a relative vacuum of -550Pa. Set the power of the vacuum induction furnace to 7kW and keep it for 5min, then adjust the power of the vacuum induction furnace to 15kW and keep it for 5min, until all the alloys form alloy liquid. Reduce the power of the vacuum induction furnace to 0kW, and then adjust the power of the vacuum induction furnace to 12kW after the alloy liquid surface forms a protective film. After the alloy protective film is opened and the alloy liquid surface is exposed, the alloy liquid is cast into a water-coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com