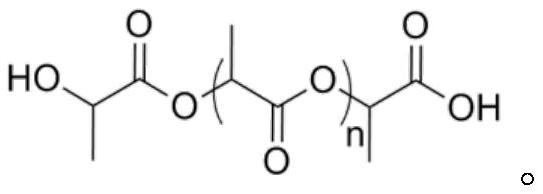

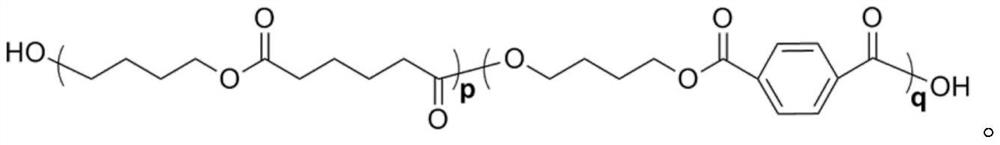

A kind of high toughness, high melt strength pla/pbat alloy based on aziridine compatibilizer and preparation method thereof

A technology of compatibilizer and aziridine, which is applied in the field of degradable polymer materials, can solve the problems of less generation of block polymers, low reactivity of compatibilizers, limited improvement of alloy toughness, etc., and achieve fast reaction rate, Excellent melt processing performance and stable melt properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

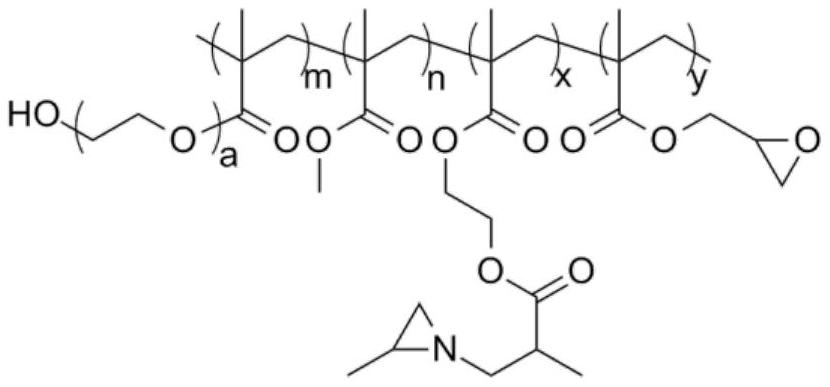

[0049] Synthesis of Aziridine Compatibilizer B

[0050] 1) Dissolve 200g of ethylene glycol dimethacrylate in 1000ml of dioxane solvent, maintain the system temperature at 25°C, slowly add 60g of 2-methylaziridine dropwise to the solvent at a flow rate of 14ml / h and stir , after the dropwise addition was completed, the reaction system was stirred at 25°C for 1 hour, then stirred at reflux at 50°C for 2 hours, and the solvent was removed by rotary evaporation at 100°C to obtain monomer C.

[0051] 2) The 1L autoclave was replaced with nitrogen for 4 times, 600ml of toluene was added to the kettle, and the temperature of the kettle was maintained at 80°C. Then, 90g of methyl methacrylate, 5.2g of methacrylic acid hydroxyl group were added dropwise to the kettle with a constant pressure dropping funnel A mixed solution of ethyl ester, 1.42g glycidyl methacrylate, 12.6g monomer C and 1g initiator azobisisobutyronitrile. After the dropwise addition, the reaction kettle was stirred...

Embodiment 2

[0053] 1) Weigh 50g PLA 2003D, 50g PBAT C1200, 0.5g aziridine compatibilizer A PZP-1000, 0.2g antioxidant 1010, place PLA and PBAT in a vacuum oven at 60°C for 4 hours for drying treatment;

[0054] 2) Add PBAT to Hapu RM-200C mixing platform and mix for 1 minute, then add PZP-1000, and mix for 2 minutes (temperature 170°C, rotor speed 50rpm);

[0055] 3) Add PLA, continue kneading for 4 minutes (temperature 170°C, rotor speed 50rpm), and finally add antioxidant 1010 to obtain PLA / PBAT alloy.

[0056] The obtained alloy was obtained by compression molding to obtain a sample bar, and the impact strength and melt index test were respectively carried out according to the ASTM D256 and ASTM D1238 standards, and the molecular weight test was carried out using gel permeation chromatography with tetrahydrofuran as the mobile phase (Shimadzu LC-20AD GPC, flow rate 1ml / min), the results are shown in Table 1.

Embodiment 3

[0058] According to Example 2, with other conditions unchanged, 0.8 g of aziridine compatibilizer B was added to the formula of Example 2 (compatibilizer B and compatibilizer A were added to the mixing platform). The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com