Hydraulic oil tank with anti-corrosion and high-temperature-resistant functions

A hydraulic oil tank, high temperature resistant technology, applied in the direction of oil supply tank device, fluid pressure actuating device, fluid pressure actuating system components, etc. problems such as poor effect, to achieve the effect of fast heat dissipation, simple structure, and accelerated heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

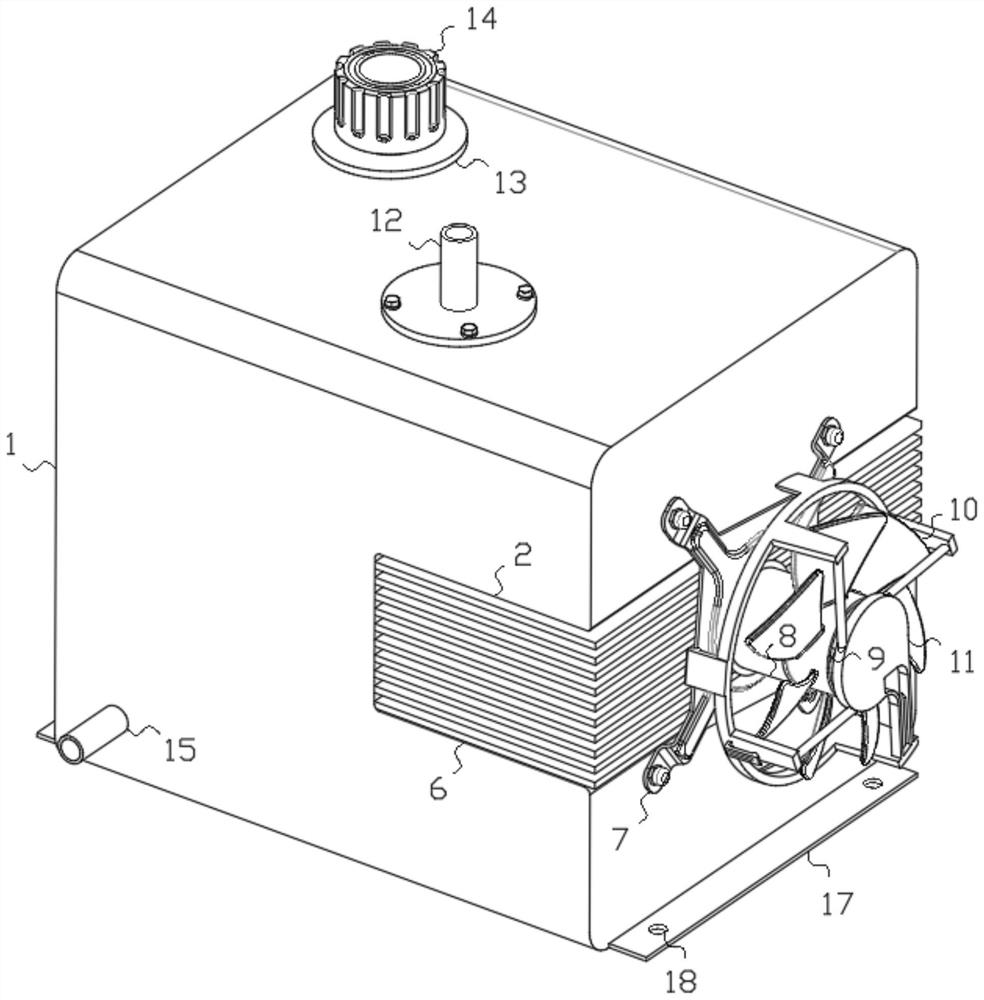

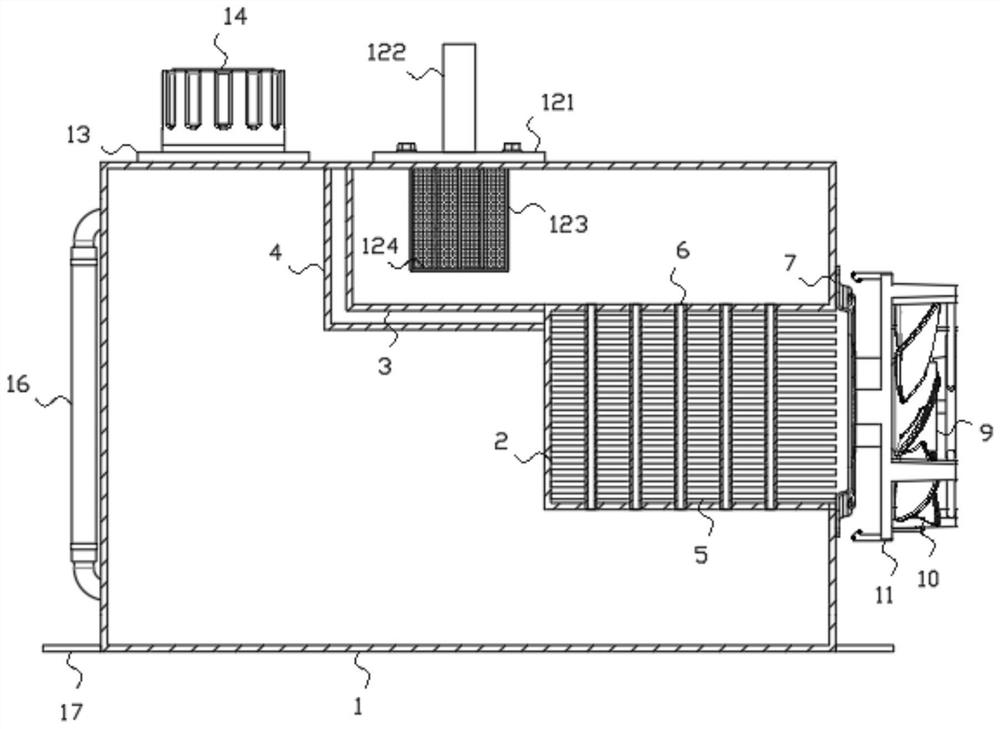

[0019] see Figure 1-3 , the present invention provides a technical solution: a hydraulic oil tank with anti-corrosion and high-temperature resistance, comprising a tank body 1, the tank body is made of composite materials, and has absolute sealing performance, anti-corrosion performance and high temperature resistance performance, thereby effectively improving the hydraulic pressure. The service life of the fuel tank, the fuel tank body 1 is provided with a mounting groove 2 on one side, the fuel tank body 1 is provided with a first partition 3 on one side of the mounting groove 2, and a second partition is provided below the first partition 3 The baffle 4, the first baffle 3 and the second baffle 4 form a vacuum structure, which avoids the phenomenon of heat exchange inside the tank body 1, and effectively separates the cold oil area and the hot oil area. The installation slot 2 is provided with a plurality of radiating fins 5 arranged at equal intervals, and a plurality of ...

Embodiment 2

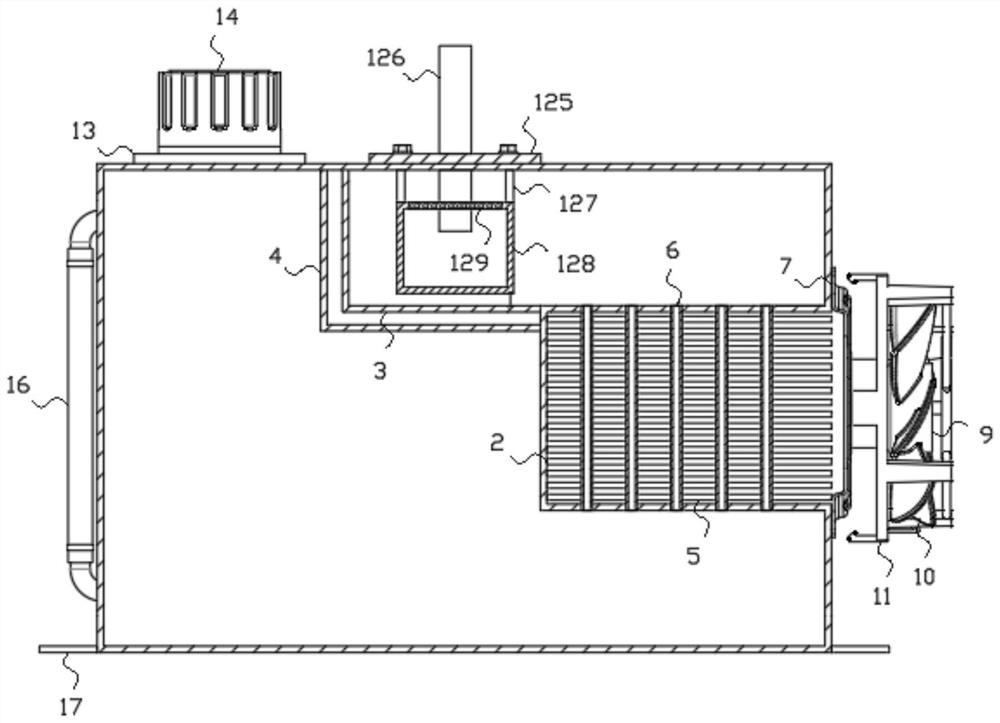

[0022] see figure 1 and 3 , the oil return assembly 12 includes a second flange 125, the second flange 125 is fixedly connected with the fuel tank body 1, and a second oil return pipe 126 is arranged in the upper middle of the second flange 125. A connecting rod 127 is provided under the second flange 125 , and the lower part of the connecting rod 127 is fixedly connected with the filter tank 128 . The upper end of the filter tank 128 is provided with a second filter screen 129 , and the lower end of the second oil return pipe 126 penetrates the first The second filter screen 129 extends to the inside of the filter tank 128, and the second flange 125 is fixedly connected to the oil tank body 1, so that the oil return assembly 12 is easy to disassemble and install, so that after the oil return assembly 12 is used for a long time, the oil return assembly 12. Clean and replace it in time. The returned hydraulic oil enters the filter tank 128 through the second oil return pipe 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com