PLC and HMI fusion algorithm

A technology that integrates algorithms and components. It is applied in other database retrieval, other database indexing, and execution paradigms. It can solve problems such as tediousness, waste of programming time, and difficulty in standardization, and achieve the effects of reducing costs and saving programming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

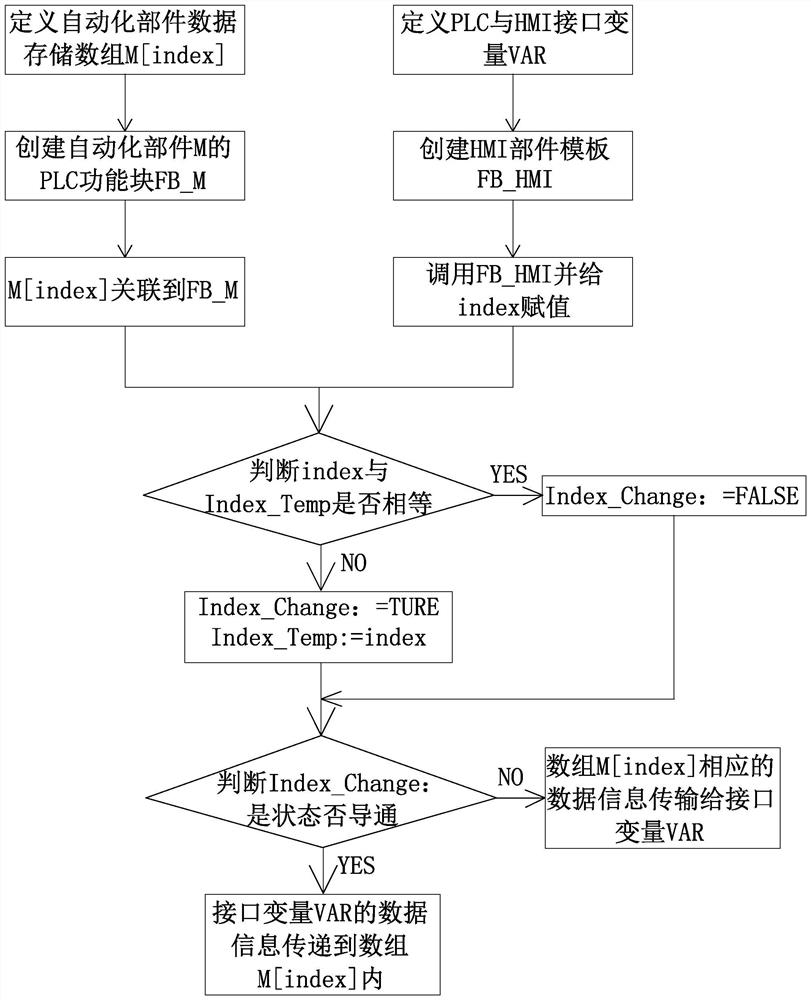

[0023] The features and principles of the present invention will be described in detail below with reference to the accompanying drawings. The examples are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

[0024] like figure 1 As shown, the storage array M[1...n] that defines the automation component M is used to store the data of n automation components M, wherein the automation component M can be automation such as servo, cylinder, motor, robot, stepper, frequency converter, etc. Any electrical device commonly used in , we take the automation component M as the servo as an example to illustrate.

[0025] In the first step, we make a structure for all the variables related to the automation component M1 (servo) and need to be associated with the HMI, such as positive jog, negative jog, return to the circle point, automatic speed, jog speed , acceleration, deceleration, teaching point 1, teaching point 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com