Aircraft engine defect identification system based on borescope image real-time analysis

An aircraft engine and defect identification technology, which is applied in the field of aircraft engine defect identification system, can solve the problems of hidden dangers of flight safety, missed detection by visual manual inspection methods, and inability to track the trend of defect changes in real time, so as to improve the recognition rate and promote the application Development, avoiding repeated checks to confirm the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

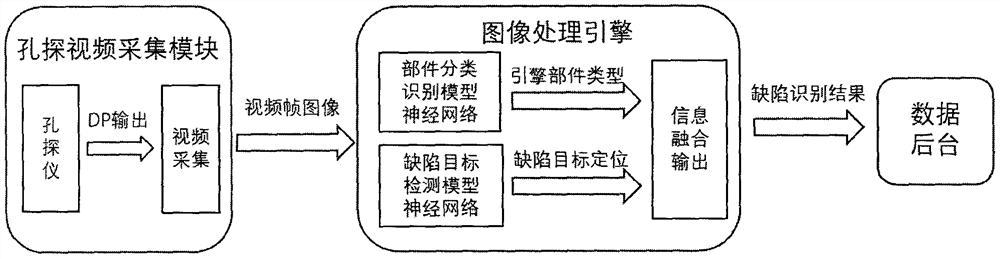

[0023] Please refer to figure 1 , the present embodiment provides an aircraft engine defect identification system based on real-time analysis of hole detection images, including:

[0024] The hole detection video acquisition module is used to collect the video images of the combustion chamber, compressor, high and low pressure turbine and other equipment components in the process of the aircraft engine hole detection operation in real time. Each frame of screenshot data is compressed and encoded by H.265 into a high-definition video with a resolution of 1920*1080 and 60 frames, and the continuous frame screenshots are transmitted to the image processing engine in real time according to the OTG transmission protocol format; the present invention adopts the hole detector and DP real-time Video collector, used by maintenance personnel during operation.

[0025] The image processing engine is connected to the hole detection video acquisition module to obtain continuous frame scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com