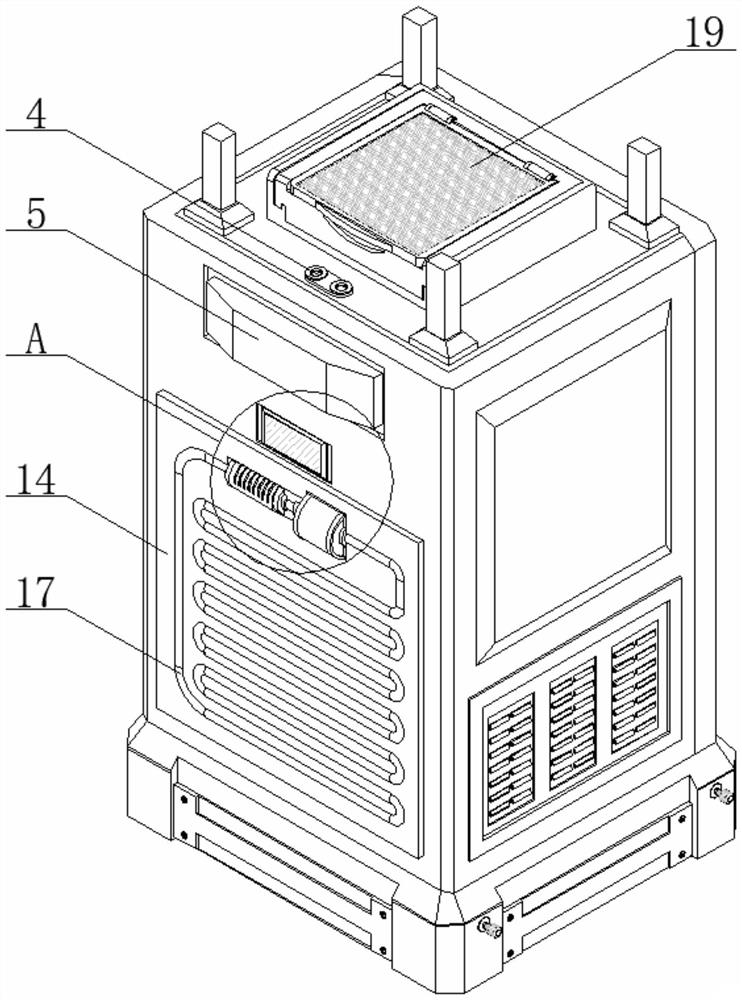

[0004] 1. The

patent document CN107424758A discloses, "an energy-saving oil-immersed transformer, the inner cavity of the transformer is divided into an oil-immersed cavity, a cooling cavity and a filter cavity by a partition, and the insulating oil in the transformer is set in the oil-immersed cavity. After heat exchange, the coil enters the

cooling chamber and the filter chamber through the

cooling pipe in turn. The spiral

pipe set in the

cooling chamber and the insulating oil filled in the

cooling chamber cool the hot oil in the

cooling pipe for the first time, and the insulating oil filled in the filter chamber The oil cools the hot oil in the cooling pipeline for the second time, and the hot oil after the second cooling flows into the filter

cartridge for

filtration. The unique filter structure inside and outside the filter

cartridge can not only filter out the larger particles in the cooling oil It can also remove

metal impurities with

small particles in the cooling oil, thereby improving the safety of the transformer operation and effectively reducing the operation and maintenance costs of the equipment.” However, this energy-saving oil-immersed transformer does not have an automatic device. The internal cooling device provides the function of

electric energy. All the

electrical equipment inside the gas device need to be improved by an external power supply, which does not meet the energy-saving requirements of the device itself. The

electrical equipment inside the device will cause a large amount of

power consumption when the external power supply is connected. Wasteful and not safe to use

[0005] 2.

Patent document CN111180166A discloses, "A cooling mechanism for an energy-saving power transformer, the structure of which includes a fixed plate, a tripod, a cooling device, a base, a support frame, a transformer, a connector, cables, bolts, lifting rings, a top plate, and a fixed The plate is welded and installed on the bottom surface of the base, the tripod and the cooling device are an integrated structure, the support frame is welded to the bottom surface of the transformer, and the cable is embedded and installed on the outer surface of the connector. This application is a cooling mechanism for an energy-saving power transformer. The structure There is a cooling device on the top, which is an integrated structure with the tripod. The natural wind enters the inside of the cooling device through the air mesh in the cooling device, and then the rotating bearing starts to run, so that the rotating rod starts to rotate. With the rotation of the rotating rod, The drum starts to rotate under force, and then the natural wind takes the heat inside the transformer out of the air mesh to the outside through the rotation of the drum, forming

air convection, and using natural wind

convection to cool the transformer, which is more energy-saving and

environmentally friendly. The cooling mechanism of the type power transformer does not have the function of using multiple

cooling methods in different temperature environments. When the external environment temperature is high, or a large number of equipment inside the device generates high temperature, the high temperature inside the device cannot pass through its own cooling

system. Separation for effective cooling cannot meet the different cooling effects under different ambient temperatures, and it is inadaptable

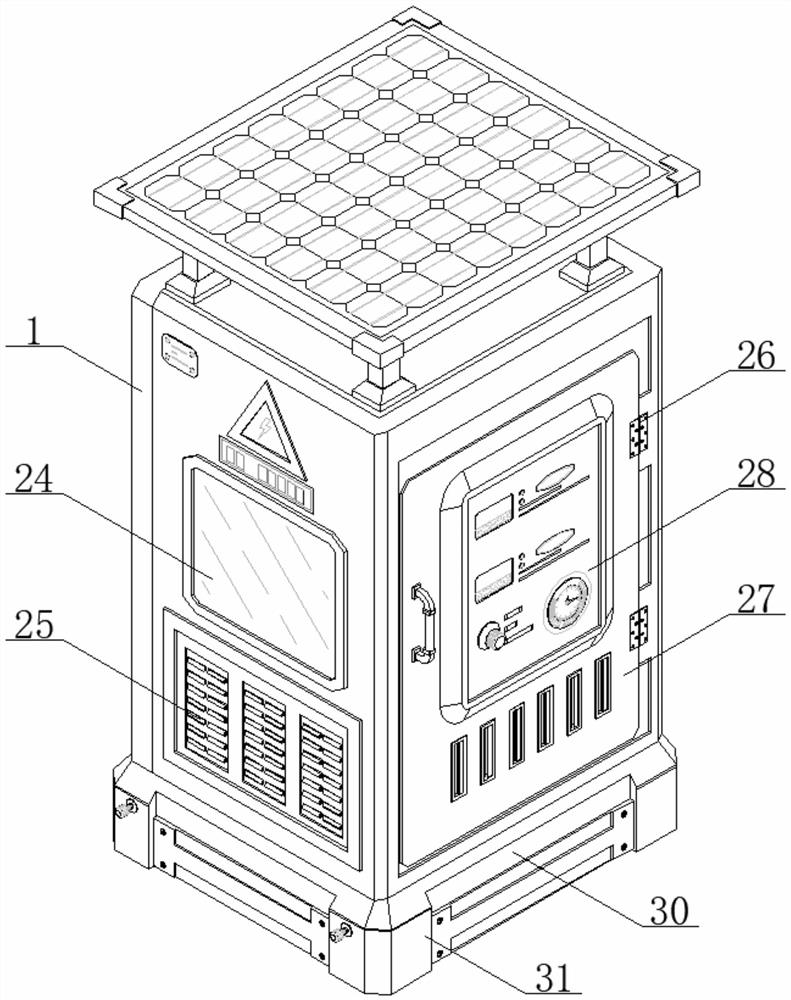

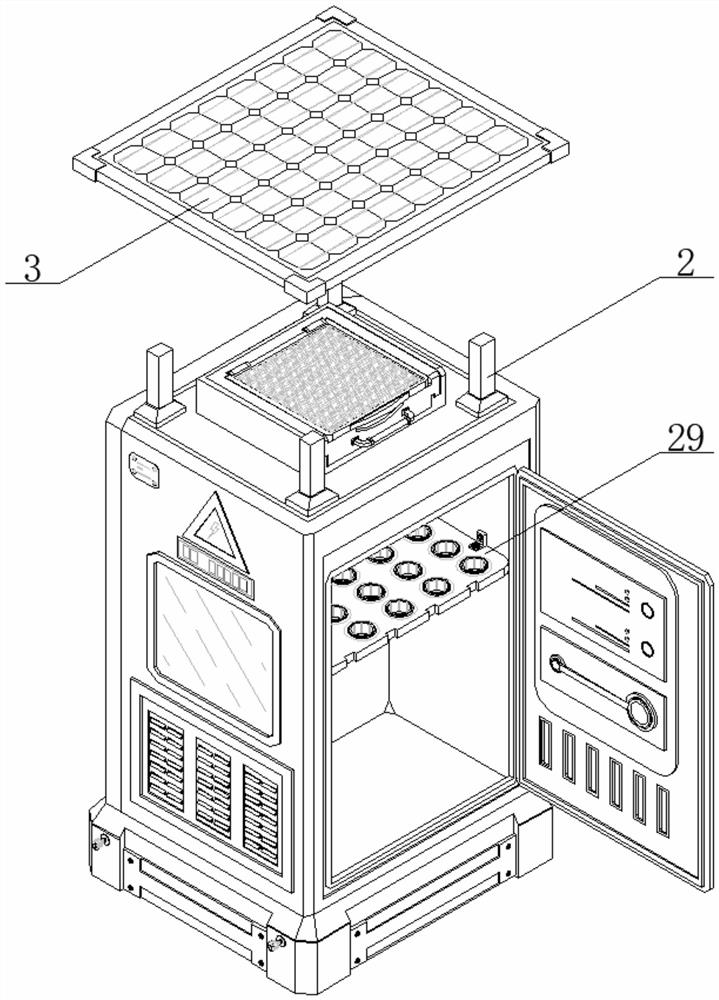

[0006] 3. The

patent document CN107316734B discloses, "

environmentally friendly and energy-saving high-safety power transformer

system, which is characterized in that it includes a transformer shell, a transformer winding body, a base, a universal wheel, a suction cup, a screw, a screw motor, a cooling fan, and an

inverter. device, solar panel, A / D converter, local central controller,

GSM module, transformer data storage device and

cloud server cluster; the transformer winding body is arranged in the transformer casing, and the transformer casing is fixedly connected to the base. A universal wheel is arranged at the lower end of the base; the base is provided with at least one threaded hole vertically penetrating the base, the

screw thread is screwed into the threaded hole, the upper end of the screw is docked with the screw

motor shaft, and the lower end of the screw is fixed with a suction cup. , but the

environmental protection and energy-saving high-safety power transformer

system does not have the protection function of

drying and dehumidifying the inside of the device. When the environment is humid or the device cools down, the

water vapor inside the device is liquefied by the temperature and condenses to produce water droplets, which fall into the electrical appliances. On the equipment, it will cause damage to the device, and the safety is not high

The embodiment of the present application can greatly improve the

cooling efficiency of the transformer and effectively utilize the energy generated by the transformer's own loss; when it is outdoors, the top heat dissipation compartment can play the role of blocking solar

radiation and absorbing

solar energy", but the top

water cooling of the energy-saving transformer The device and its control method do not provide a method of portability and movement. The large-scale transformer equipment itself is relatively heavy. When the equipment is moved and installed, it needs to use external equipment to intervene and move it. The movement of the device by the staff is time-consuming and labor-intensive.

Login to View More

Login to View More  Login to View More

Login to View More