Internal cleaning device for lubricating oil pipeline of steam turbine generator unit

A steam turbine generator set, internal cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of intricate transportation pipelines, large safety hazards, and long construction periods, and achieve pipeline The effect of cleaning the inner wall, reducing chemical cleaning work, and shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments; the following embodiments are not intended to limit the present invention, but only serve as a way to support the realization of the present invention. Any equivalent structure replacement within the technical framework disclosed in the present invention is the present invention. the scope of protection of the invention;

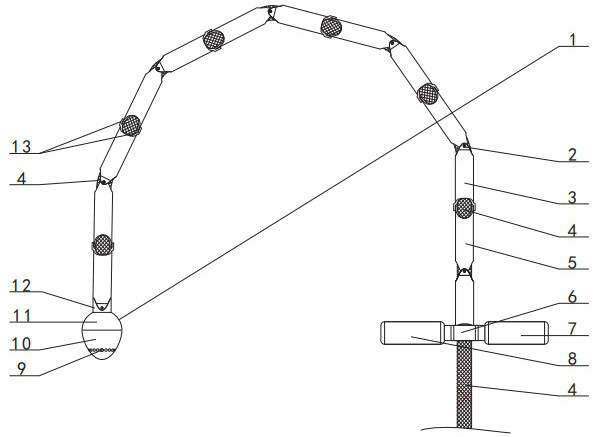

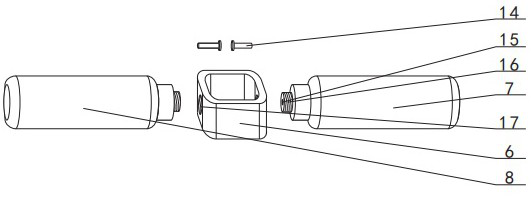

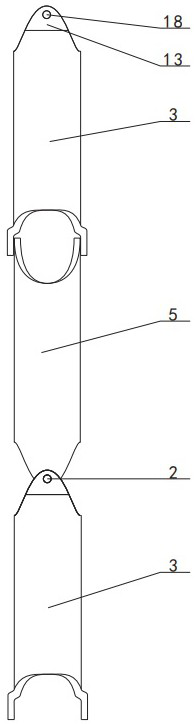

[0027] combined with Figures 1 to 8 The internal cleaning device for the lubricating oil pipeline of the steam turbine generator set described in , includes an elliptical ball 1, a high temperature steam hose 4, a multi-section universal sleeve, a collar 6 and a control handle, on the front hemisphere 10 of the elliptical ball 1 There is a surrounding steam discharge hole 9, the connecting pipe 12 provided at the rear end of the rear hemisphere 11 of the elliptical sphere 1 is fixedly connected with the front end of the high temperature resistant steam hose 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com