Numerical control machining tool with error self-correction function

A technology of CNC machine tools and CNC machine tools, which is applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting processing and use, inaccurate aperture measurement, and no correction, to prevent high temperature burns, Improve the effect of error correction and reduce the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

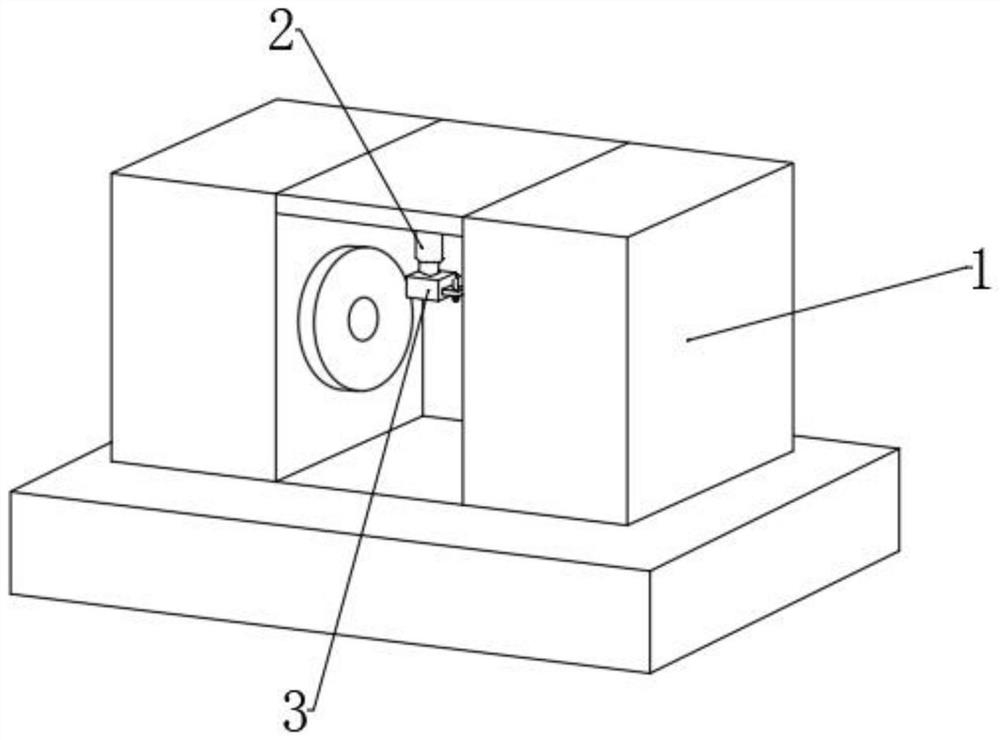

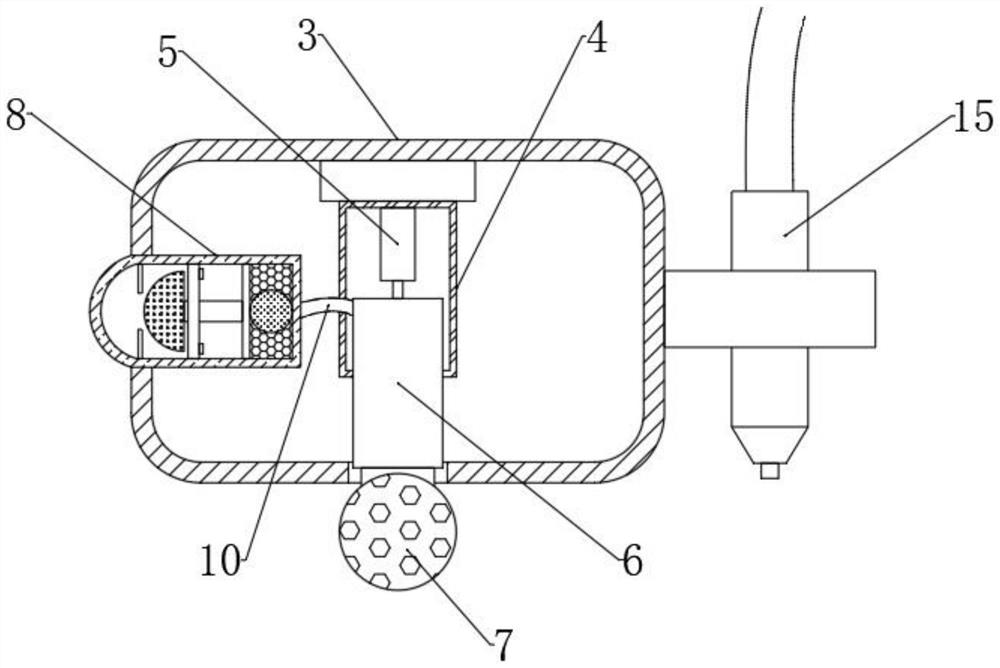

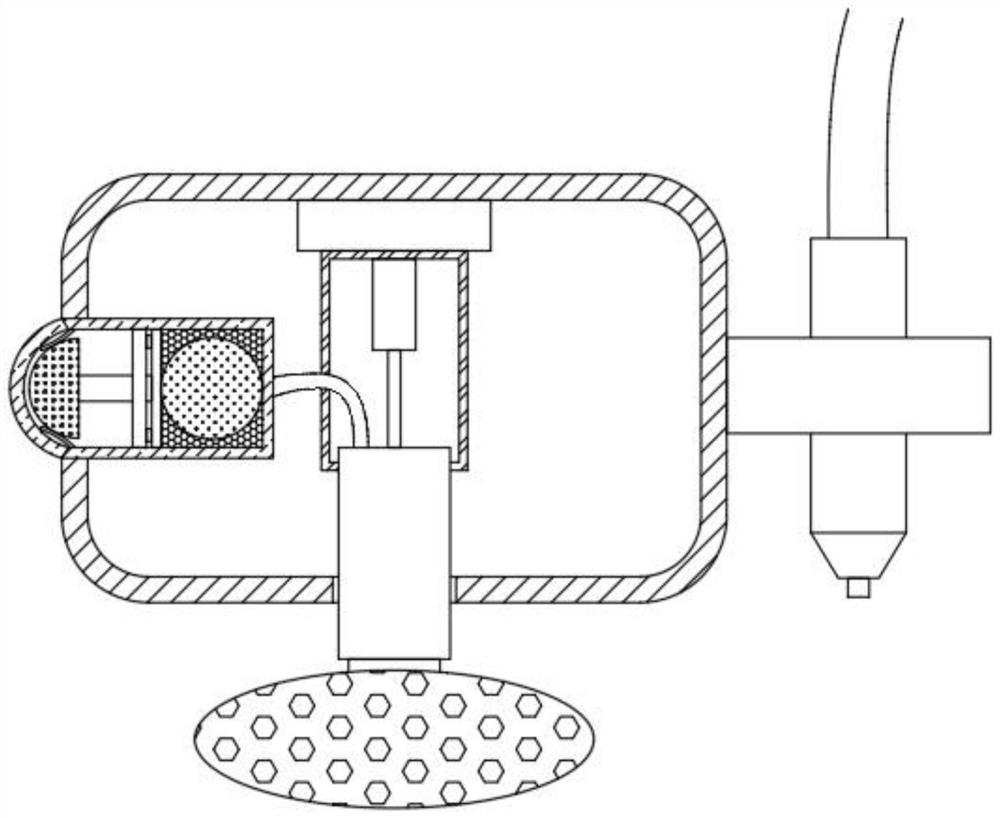

[0046] see Figure 1-8 , a CNC machining machine with error self-correction function, see figure 1 , 2 , 8, including the CNC machine tool body 1, the CNC machine tool body 1 includes a thermal deformation correction processor, the thermal deformation correction processor includes a heat detection module and a cooling module, and the heat detection module includes a starter telescopic rod slidably connected to the top of the CNC machine tool body 1 One 2, and the lower end of the start-up telescopic rod one 2 is fixedly connected with the outer heat insulation shell 3, the upper end inner wall of the outer heat insulation shell 3 is fixedly connected with the inner heat insulation shell 4, and the upper end inner wall of the inner heat insulation shell 4 is fixedly connected with the A start-up telescopic rod 25 electrically connected to the heat detection module;

[0047] see figure 2 , 3 , 4, 5, the output end of the start-up telescopic rod 5 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com