Turning type staircase formwork one-time forming and multi-time pouring construction method

A construction method and stairwell technology, which is applied in the direction of formwork/formwork/working frame, stairs, buildings, etc., can solve the problems of wrong platform, slurry leakage, rotten roots, etc., and achieve the goals of speeding up the construction progress, easy installation, and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

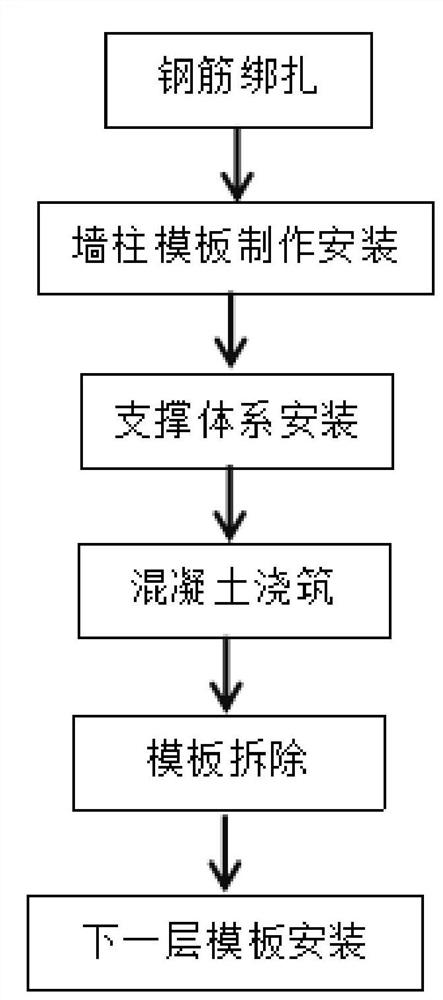

[0029] according to Figure 1-Figure 2 As shown, the present embodiment proposes a construction method for one-time forming and sub-casting of a turning-type stairwell formwork, comprising the following steps:

[0030] Step 1. Rebar binding

[0031] First, tie the steel bars of the floors and beams, and then position the steel bars of the stairwell wall panels. After the steel bars are positioned, the steel bars of the stairwell wall columns are bound. After the steel bar binding operation is completed, it is checked and accepted. , For the unqualified part, it needs to be re-bundled until it is qualified. Before the acceptance of the steel bar binding, it is necessary to deal with the construction joint of the wall, rinse it after treatment, and then accept it. The treatment is done within 3mm of the wall column edge Play another cutting line, cut with a toothless saw, the cutting depth is 10mm, after the cutting is completed, remove the weak layer of the horizontal construc...

Embodiment 2

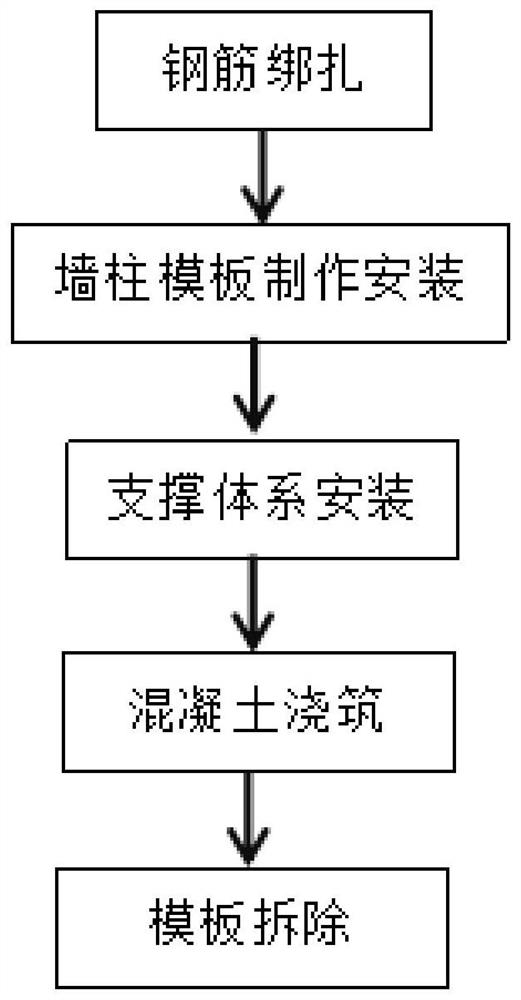

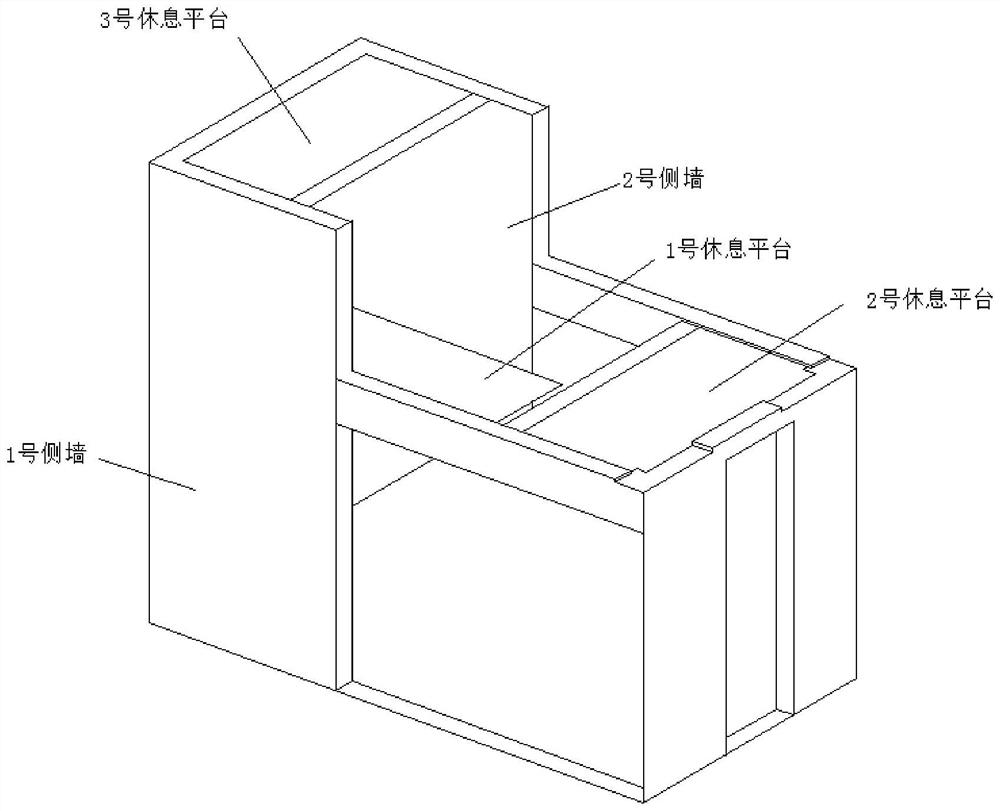

[0043] according to image 3 As shown in the figure, the present embodiment proposes a construction method of one-time molding and staged pouring of a turning-type stairwell formwork, step 1, reinforcing steel bar binding

[0044] First, tie the steel bars of the floors and beams, and then position the steel bars of the stairwell wall panels. After the steel bars are positioned, the steel bars of the stairwell wall columns are bound. After the steel bar binding operation is completed, it is checked and accepted. , For the unqualified part, it needs to be re-bundled until it is qualified. Before the acceptance of the steel bar binding, it is necessary to deal with the construction joint of the wall, rinse it after treatment, and then accept it. The treatment is done within 3mm of the wall column edge Play another cutting line, cut with a toothless saw, the cutting depth is 10mm, after the cutting is completed, remove the weak layer of the horizontal construction mortar, expose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com