Pipeline inner wall wiping and sampling device operated at single end

The technology of sampling device and pipeline is applied in the field of survey sampling device for inner wall of pipeline to achieve the effect of enhancing wiping effect, balancing frictional resistance and facilitating wiping and sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

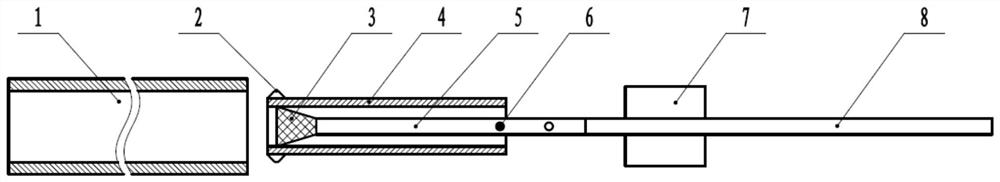

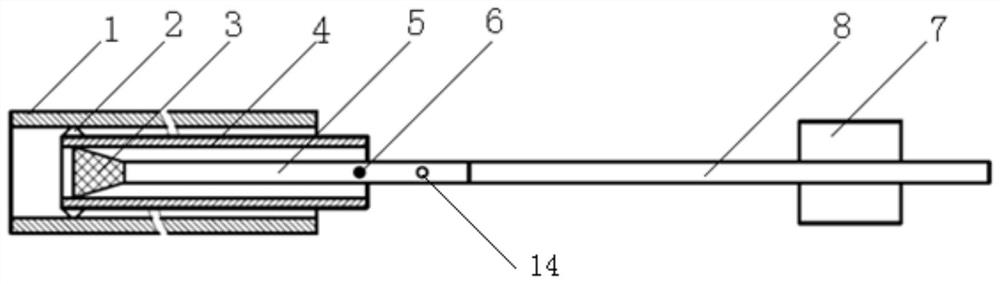

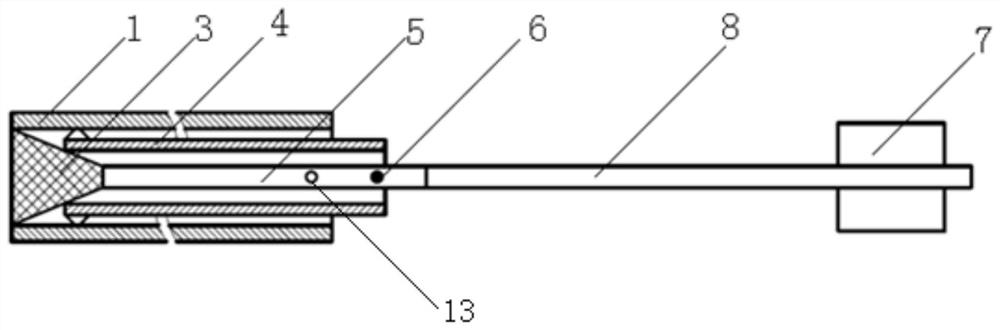

[0047] like figure 1 As shown, the present invention is a single-end operated pipe inner wall wiping sampling device, comprising a support assembly 2, an elastic body 3, an operating mechanism and a driving mechanism connected with the operating mechanism; the driving mechanism is used to drive the operating mechanism to move in the axial direction;

[0048] The operating mechanism includes an inner push rod 5, a restraint assembly 4 sleeved on the inner push rod 5, and a positioning assembly 6; an accommodation cavity is formed between the inner push rod 5 and the restraint assembly 4; one end of the inner push rod 5 is connected to the The elastic body 3 is connected, and the other end is connected with the driving mechanism; the other end of the inner push rod 5 is provided with a first positioning hole 13 and a second positioning hole 14; the end of the restraint assembly 4 close to the inner push rod 5 is provided with a third positioning hole The positioning assembly 6 p...

Embodiment 2

[0060] like Figure 7 As shown, the difference between this embodiment and the first embodiment is that the constraining assembly 4 includes a constraining cylinder 15 sleeved on the inner push rod 5, a ring assembly 11 and a connecting pipe 12; one end of the connecting pipe 12 is connected to the constraining cylinder 15, The other end is connected with the ring assembly 11; the third positioning hole is arranged on the ring assembly 11;

[0061] An accommodating cavity is formed between the inner push rod 5 and the restraining cylinder 15 ; the support assembly 2 is arranged on the outer wall of the restraining cylinder 15 . The ring assembly 11 and the connecting pipe 12 used in this embodiment can reduce the weight of the restraint assembly 4, thereby reducing the weight of the operating mechanism, making the wiping and sampling operation more convenient.

[0062] The rest of this embodiment is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com