Heat transfer analysis model for medium-deep layer buried pipe heat exchanger

An analysis model and heat exchanger technology, applied in geothermal power generation, instrumentation, design optimization/simulation, etc., can solve problems such as a single heat extraction scenario, achieve optimal control and energy-saving operation, efficient simulation calculation, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] In order to make those skilled in the art better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings.

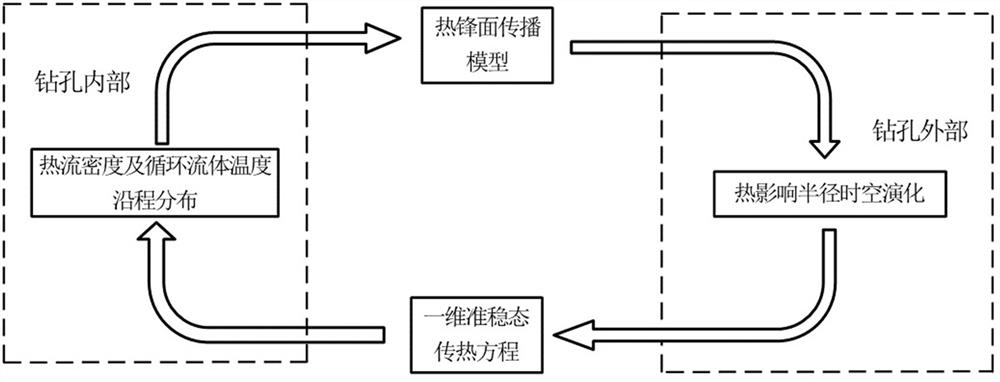

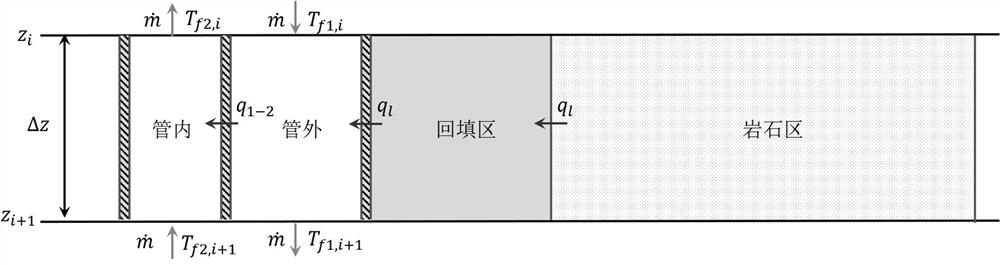

[0114] The analysis method of the heat transfer analysis model of medium-deep borehole heat exchangers based on thermal front propagation and extended finite-length line heat source model proposed in this scheme includes the following steps:

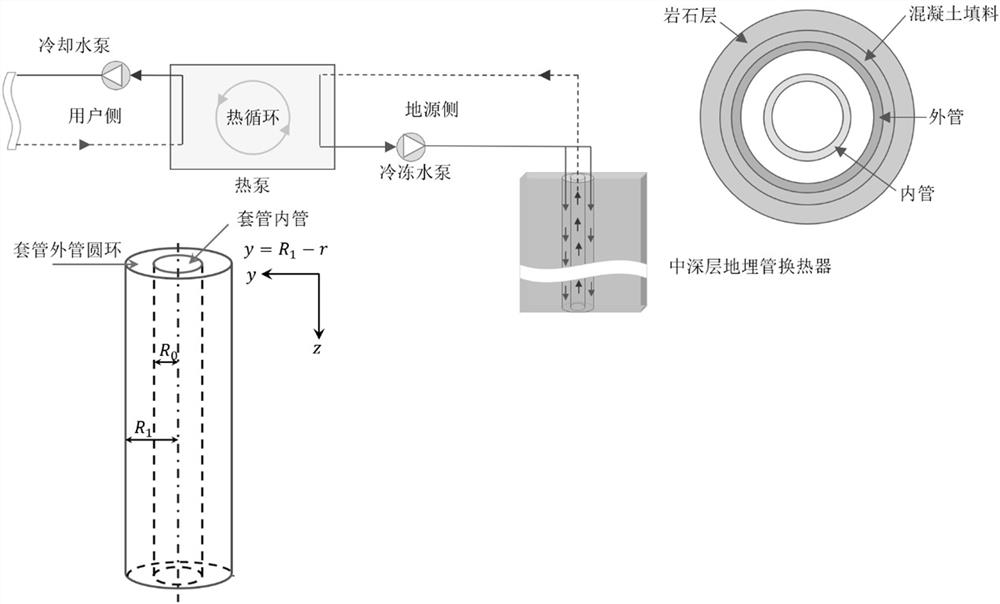

[0115] S1: as figure 1 , according to the geothermal exploration data and rock thermal property test data in the area where the actual geothermal well is located, combined with the actual operation of the middle-deep ground source heat pump system to determine the geological parameters of the heat transfer problem of the middle-deep buried tube heat exchanger; Heater structural parameters, including: borehole diameter, well depth, casing inner diameter and outer diameter; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com