Transverse linear motor structure

A linear motor, horizontal technology, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems affecting the absolute K value of the vibration system, affecting the natural frequency of the product, affecting the stress concentration of shrapnel, etc., to achieve improvement Effect of directional drop feasibility, improvement of drop feasibility, and reduction of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

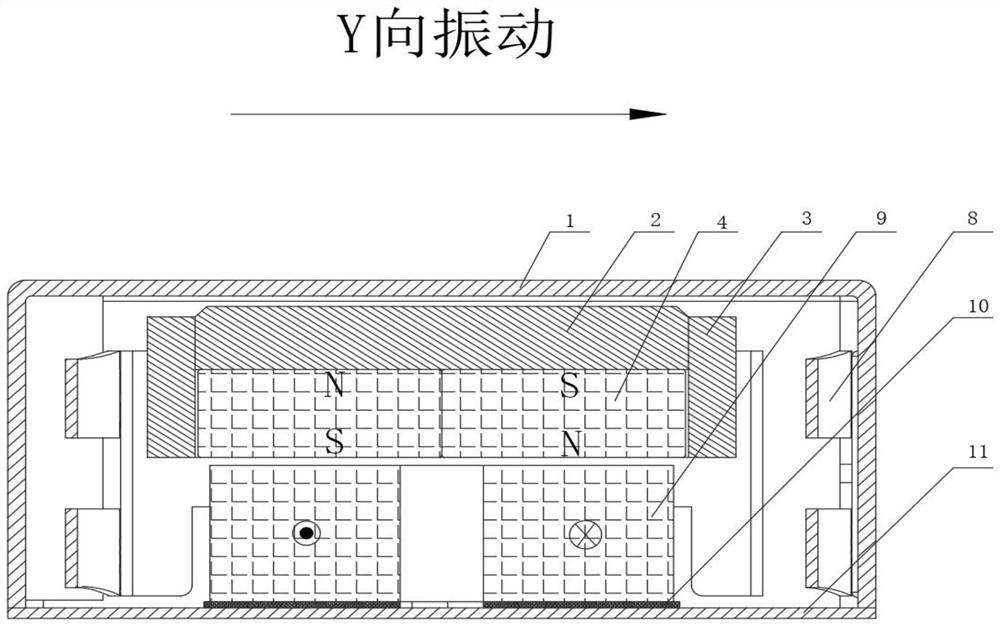

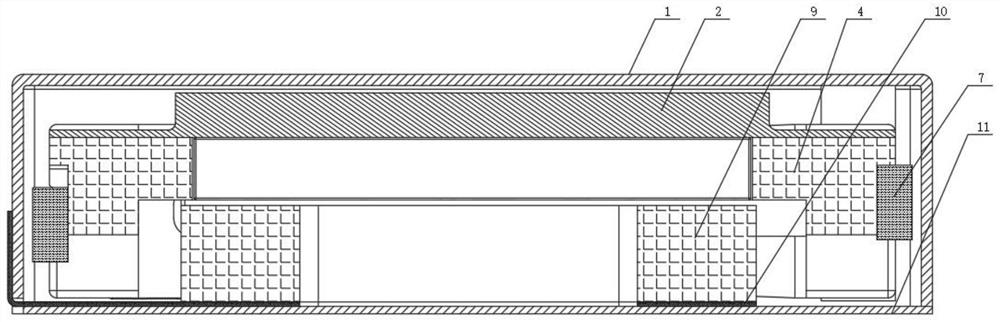

[0029] A horizontal linear motor structure, comprising a lower casing 11, an upper casing 1, a circuit board 10, a coil 9, a weight portion and an elastic sheet 8, a circuit board is arranged on the upper surface of the lower casing, and the coil is arranged on the circuit board In the upper part, the lower casing, the circuit board and the coil constitute the stator; the upper casing is empty inside, forming the outer contour of the vibration device, the weight part includes a magnetic slot assembly, and the magnetic slot assembly includes a mass block 5 , a magnetic guide plate 1 2 and a magnetic guide plate 2 3, the two sides of the magnetic guide plate 2 are symmetrically fixed with mass blocks to form a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com