Oxygen-enriched ladle baking device and ladle baking method thereof

An oxygen-enriched, baking bun technology, applied in the field of metallurgy, can solve the problems of short service life of the reversing valve, hidden dangers in safety production, insufficient combustion, etc., and achieve the effects of increasing the flame spray pressure, improving the safety factor, and improving the quality of the baking bun.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

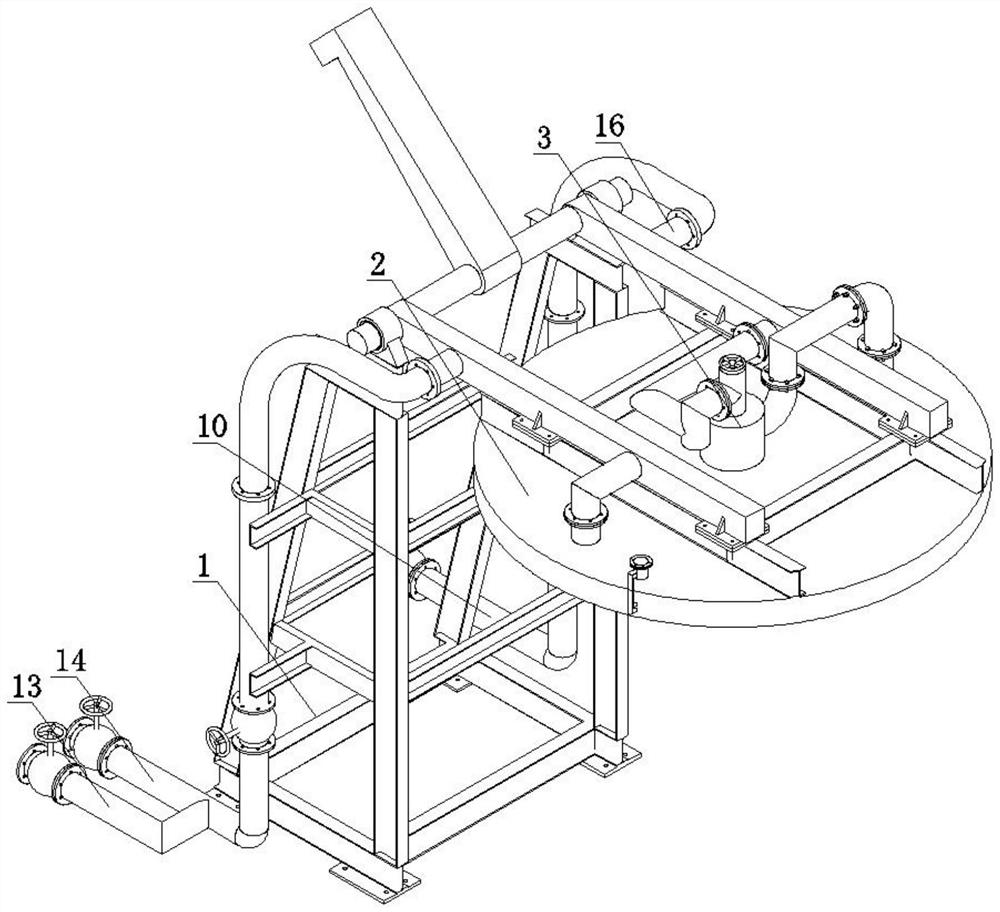

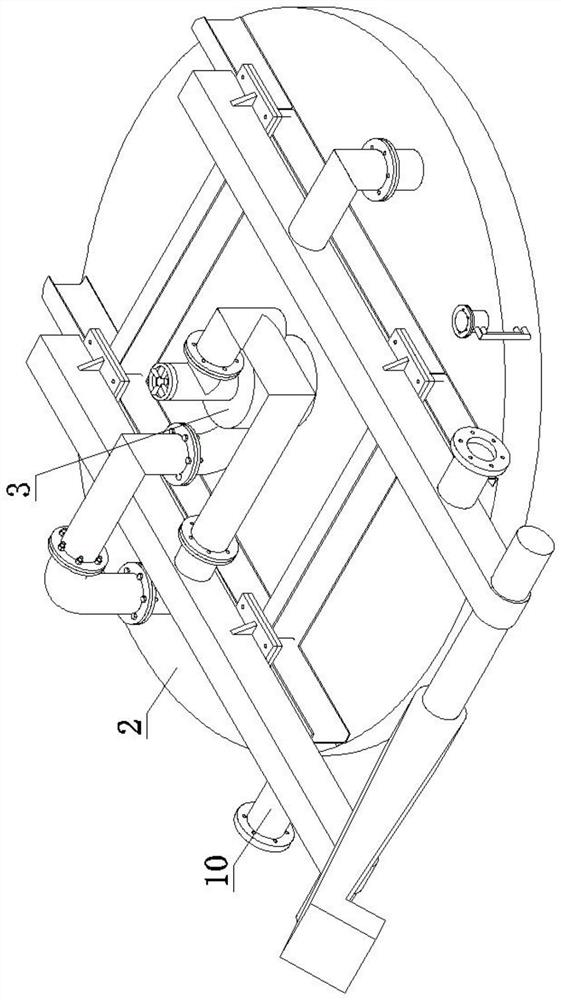

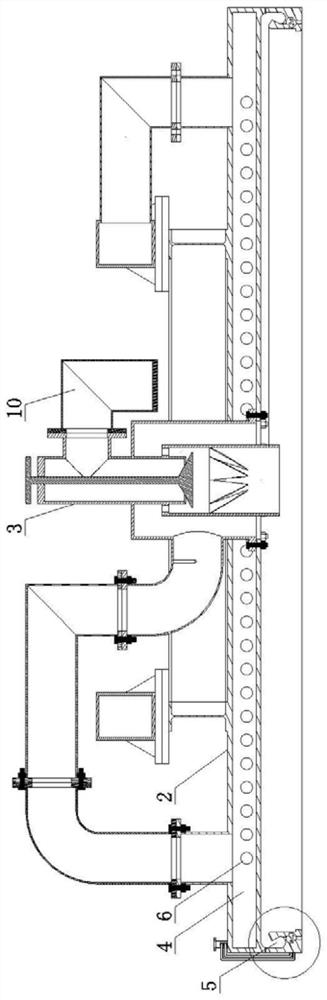

[0037] Example 1, refer to Figure 1-5 , an oxygen-enriched baking bag device, comprising a rack 1 and a cover 2 installed on the rack 1 for covering the mouth of the ladle, the rack 1 can be constructed from profiles, and the rack 1 can be configured with a lifting cover 2 hoist and work with it, the cover 2 is installed with a burner 3, the burner 3 can be selected according to the needs of the existing technology, and the specific material can be 0Cr25Ni20 stainless steel, which can operate at a high temperature of 1200 degrees for a long time. It includes a gas pipeline 4 and an oxygen-enriched gas pipeline that is connected to the burner 3 on the rack 1 and the cover 2, and the cover 2 has a function for improving the combustion of the oxygen-enriched baking bun. A high-rate oxygen-enriched gas heating chamber 4 and a tempering tank 5 for treating the open flame between the cover 2 and the ladle mouth;

[0038] The oxygen-enriched gas heating chamber 4 is provided with a...

Embodiment 2

[0040] Embodiment 2, the oxygen-enriched baking bag device described in Embodiment 1, the gas pipeline includes a gas pipe 10 arranged on the rack 1 and the bag cover 2, the gas pipe 10 is a DN200 pipe, and the gas pipe is The pipe 10 is provided with a stop valve, a gas electric blind valve 11, a pressure transmitter, a mechanical pressure gauge, a gas drain valve 12, a pneumatic butterfly valve and a pneumatic control valve in sequence according to the gas flow direction. The stop valve is a manual stop valve, and the mechanical pressure The table shows the specification of 0-30MPa. The oxygen-enriched gas pipeline includes a compressed air pipe 13 and an oxygen pipe 14 arranged on the frame 1 and the cover 2. The specification of the compressed air pipe 13 is DN100. According to the flow direction of the gas, a stop valve, a compressed air tank 15 with a mechanical pressure gauge, a pressure transmitter, a pneumatic stop valve, a flow regulating valve, a mechanical pressure ...

Embodiment 3

[0041] Embodiment 3, an oxygen-enriched baking bag device described in Embodiment 1, an annular mounting seat 18 is fixedly arranged on the bag cover 2 below the oxygen-enriching gas heating chamber 4, and the inner peripheral surface of the bottom of the annular mounting seat 18 is fixed. An annular nitrogen seat 19 is fixed and extended inward, and an annular guide seat 20 is fixed on the top surface of the annular nitrogen seat 19. The top surface of the annular guide seat 20 and the inner wall of the cover 2 below the oxygen-enriched gas heating chamber 4 are reserved. There is a moving port 21 for guiding the moving open flame. The space formed between the inner wall of the annular mounting seat 18, the upper part of the annular nitrogen seat 19 and the outer wall of the annular guiding seat 20 constitutes the tempering groove 5. The contact part of the inner wall of the upper end of the annular mounting seat 18 and the cover 2 has rounded corners and is set as a tempering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com