In-plane rod sliding mechanism

A sliding mechanism and plane technology, applied in processing drive devices, additive processing, etc., can solve problems such as difficult synchronous operation of two sets of motors, increased consumption of 3D printing equipment, and unstable operation of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

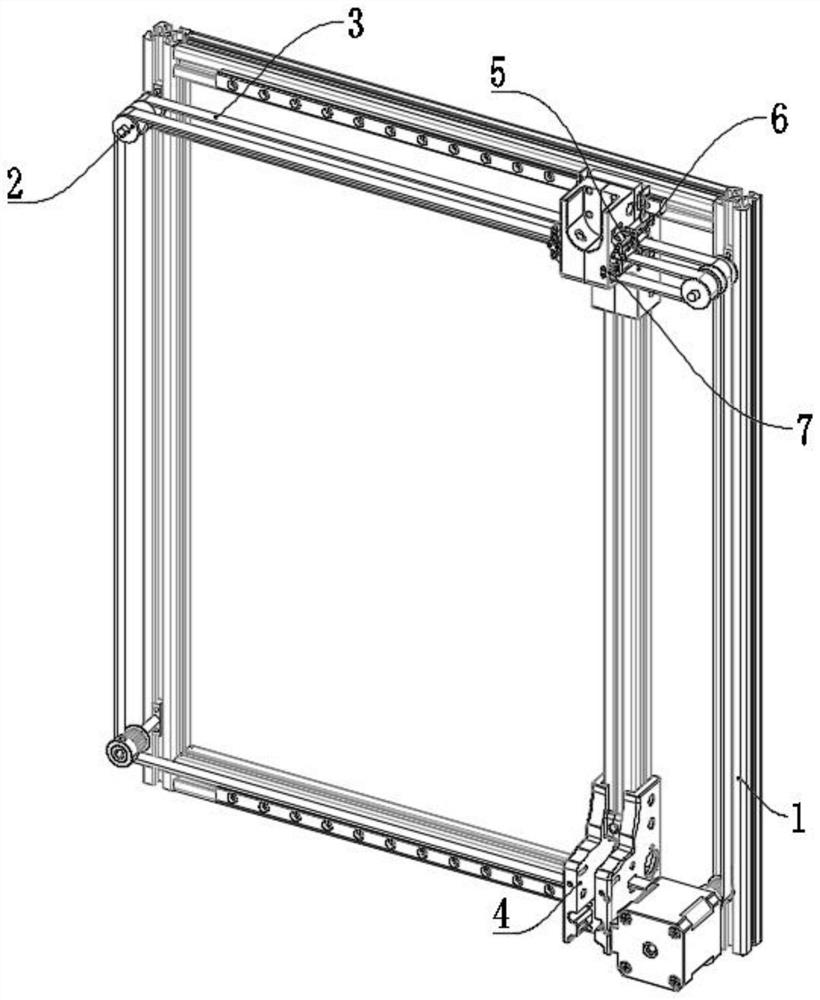

[0035] Example: please refer to Figure 1 to Figure 9 :

[0036] The present invention proposes an in-plane rod sliding mechanism, comprising: a main frame assembly 1 ; a guide wheel component 2 is rotatably mounted on the main frame assembly 1 .

[0037] In addition, according to the embodiment of the present invention, the main frame assembly 1 includes: an installation frame 101, the installation frame 101 is formed of a frame structure by fixing rods, and four sets of installation columns 102 are arranged on the outer side of the installation frame 101, and each group is installed The column 102 is stably fixed by screws, and the mounting column 102 is set to be fixed on the mounting frame 101 by two sets of screws, which can not only adjust the corresponding position of the mounting column 102, but also make the mounting column 102 more stable after fixing. 102 has a "T"-shaped structure, and the installation column 102 is set to a "T"-shaped structure, so that the insta...

Embodiment 2

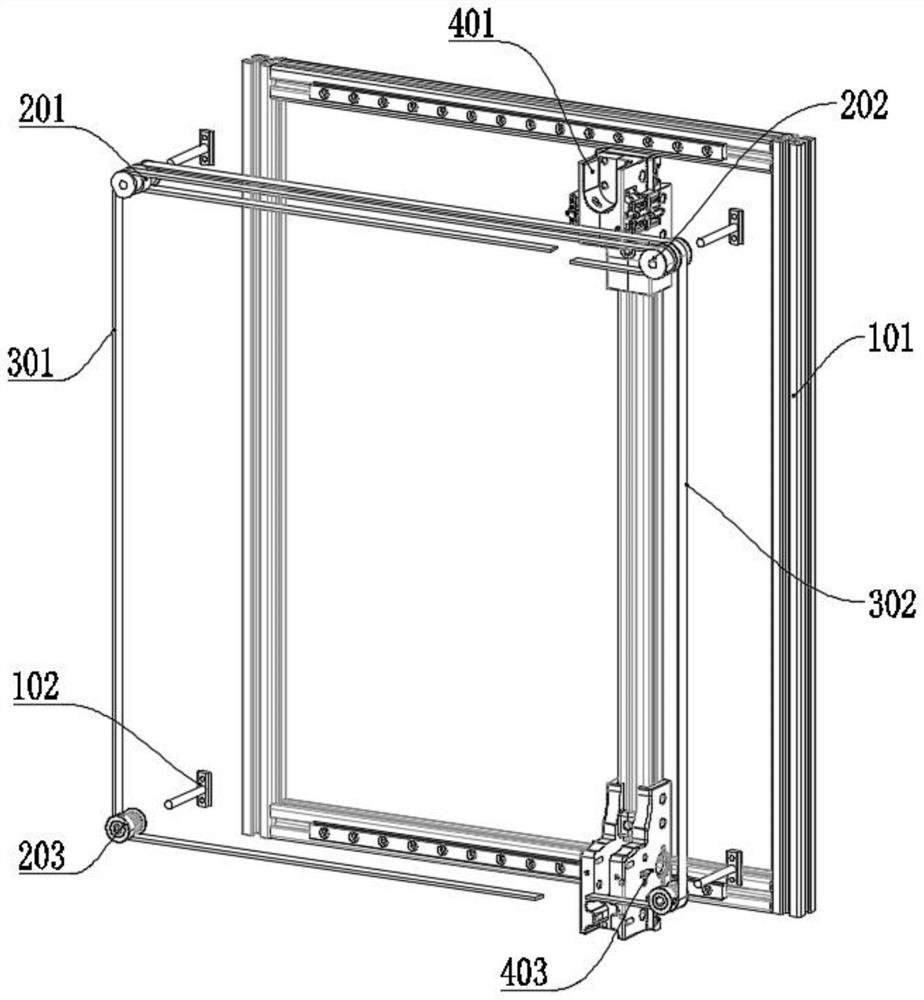

[0041] It includes: a transmission part 3 is wound and installed on the guide wheel part 2 , and a sliding part 4 is slidably installed on the main frame assembly 1 .

[0042] In addition, according to the embodiment of the present invention, the transmission member 3 includes: an outer timing belt 301, the outer timing belt 301 is wound on the guide wheel member 2 at the outer end portion, and the end of the outer timing belt 301 is connected with the sliding member 4, The inner synchronous belt 302 is wound on the guide wheel member 2 at the inner end position, and the ends of the same inner synchronous belt 302 are connected with the sliding member 4, and the outer synchronous belt 301 and the inner synchronous belt 302 are wound on the guide wheel member 2, and The ends of the inner synchronous belt 302 and the outer synchronous belt 301 are both connected to the sliding member 4, so that the outer synchronous belt 301 and the inner synchronous belt 302 form a closed frame ...

Embodiment 3

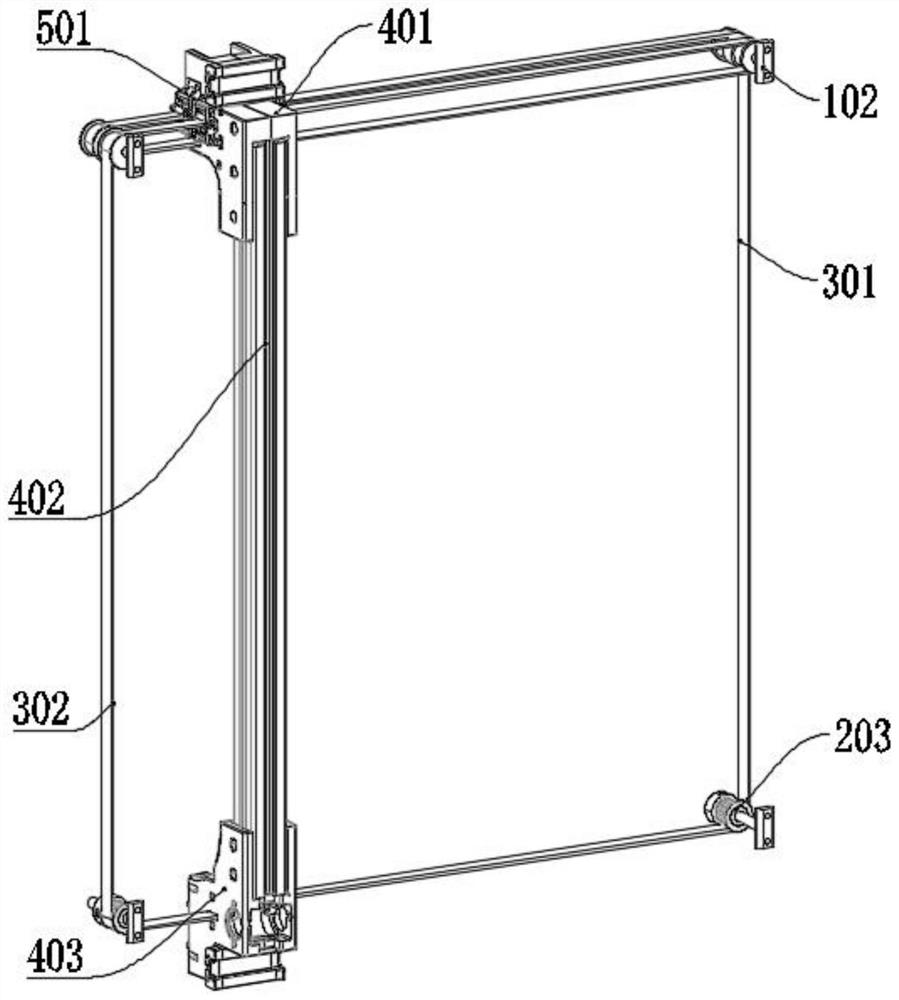

[0046] Including: the position of the sliding part 4 is provided with the installation part 5, the buffer assembly 6 is slidably installed on the installation part 5, the sliding part 4 is installed with the tensioning assembly 7 through the adjusting assembly 8, and the transmission part 3 is installed on the sliding part through the tensioning assembly 7. 4 on.

[0047] In addition, according to the embodiment of the present invention, the installation part 5 includes: an installation block 501, the installation block 501 is fixed on the outer wall of the sliding part 4, and the installation block 501 has two structures of inclination and vertical. 501 is set in two structures of inclination and vertical, so that the buffer assembly 6 can be more stably installed on the subsequent installation block 501. The front and rear positions of the top of the installation block 501 are provided with protruding heads 502, and the protruding heads 502 are arranged on the installation bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com