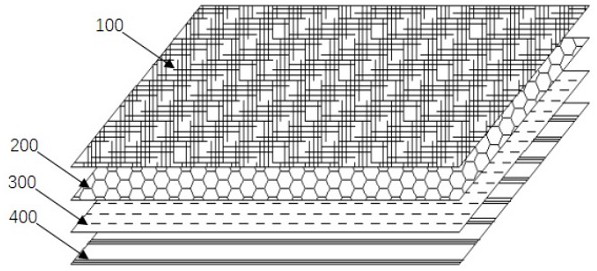

Nanofiber thermal insulation material and preparation method thereof

A nanofiber and thermal insulation layer technology, applied in the field of nanocomposite fabrics and their preparation, can solve the problems of poor thermal insulation performance, lack of far-infrared self-heating function, complicated preparation process of aerogel, etc., and achieves high moisture permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

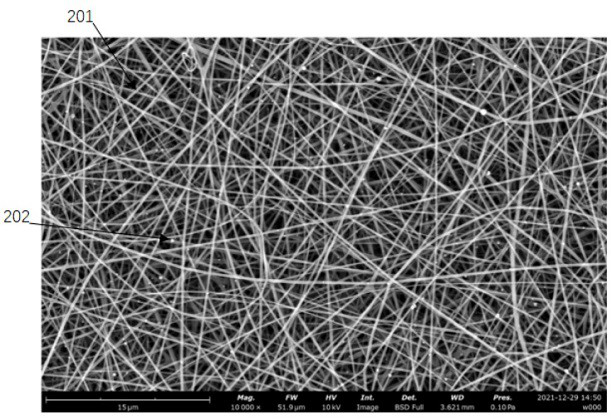

[0037] Polyurethane with a molecular weight of 200k was dissolved in DMF and HFIP was added, wherein the concentration of polyurethane was 25wt%, the concentration of DMF was 45wt%, and the concentration of additives was 20wt%. The solution was stirred evenly and divided into 2 equal parts.

[0038] A polyurethane solution is mixed with nano-zirconia particles to prepare a polyurethane-zirconia emulsion. The average diameter of the zirconia nanoparticles is 10 nm, and the solid content of the particles in the emulsion is 1 wt%.

[0039]The polyurethane-zirconia emulsion was spun with needle electrospinning equipment to prepare nanofiber waterproof and moisture-permeable porous membrane with far-infrared function. The film thickness is 15μm, the gram weight is 6gsm, and the moisture permeability is 20000g / m 2 / 24h or more, the hydrostatic pressure resistance performance is more than 10m.

[0040] Another part of the polyurethane solution was taken as the shell solution of coa...

example 2

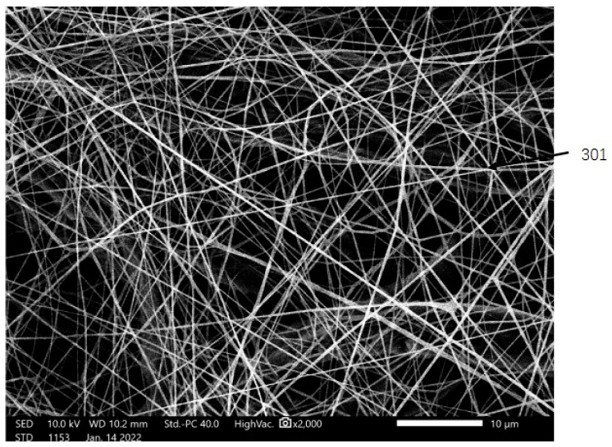

[0047] A high molecular weight polyurethane with a molecular weight of 800k was dissolved in DMF and HFIP was added, wherein the concentration of polyurethane was 8wt%, the concentration of DMF was 88wt%, and the concentration of additives was 4wt%. The solution was stirred evenly and divided into 2 equal parts.

[0048] A polyurethane solution was mixed with nano-zirconia particles to prepare a polyurethane-zirconia emulsion. The average diameter of the zirconia nanoparticles was 300 nm, and the solid content of the particles in the emulsion was 10 wt%.

[0049] The polyurethane-zirconia emulsion was spun with needle electrospinning equipment to prepare nanofiber waterproof and moisture-permeable porous membrane with far-infrared function. The film thickness is 20μm, the gram weight is 15gsm, and the moisture permeability is 10000g / m 2 / 24h or more, the hydrostatic pressure resistance is more than 20m.

[0050] Another part of the polyurethane solution was taken as the shel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com