Polyolefin master batch as well as preparation method and application thereof

A technology of polyolefin and olefin master is applied in the fields of long-term heat aging resistant ABS composite material and its preparation, polyolefin master batch and its preparation field, which can solve the problems of poor long-term heat aging resistance and poor appearance, and achieve good appearance, The effect of improving long-term aging resistance and excellent long-term thermal aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

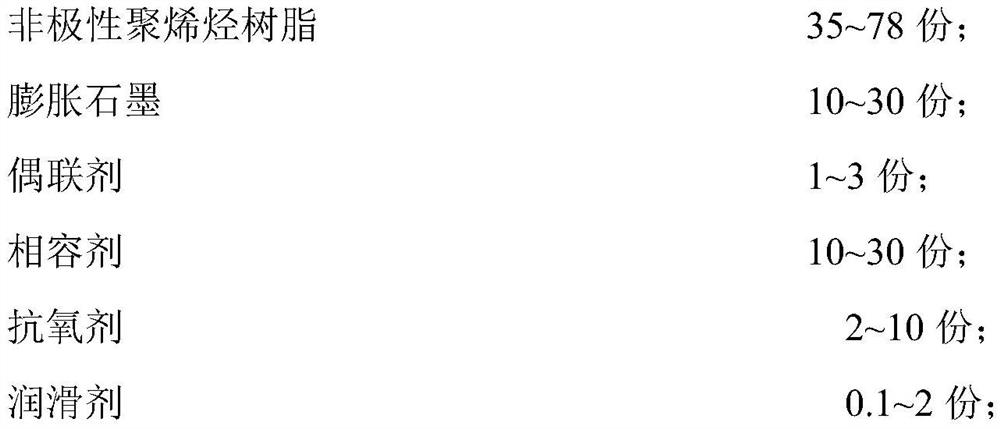

[0070] A polyolefin masterbatch, in parts by weight, comprises the following components:

[0071] Non-polar polyolefin resin; expanded graphite; coupling agent; compatibilizer; antioxidant; lubricant

[0072] The specific content of each component is shown in Table 1 below.

[0073] The composition of polyolefin masterbatch of each embodiment of table 1 (in parts by weight)

[0074] 1 2 3 Non-polar polyolefin resin 1 57.6 35 78 Expanded Graphite 1 20 30 10 coupling agent 2 3 1 Compatibilizer 20 30 10 Antioxidant 4 10 2 lubricant 0.2 0.2 0.2

[0075] Continued from Table 1

[0076] 4 5 6 7 8 9 Non-polar polyolefin resin 1 57.6 57.6 57.6 Non-polar polyolefin resin 2 57.6 Non-polar polyolefin resin 3 57.6 Non-polar polyolefin resin 4 57.6 Expanded Graphite 1 20 20 20 Expanded graphite 2 20 Expanded grap...

Embodiment 10

[0080] A long-term heat aging-resistant ABS composite material, in parts by weight, comprising the following components:

[0081] 90 parts of ABS resin; 10 parts of masterbatch; 0.4 part of weathering agent; 0.2 part of lubricant;

[0082] Described master batch is the polyolefin master batch in embodiment 1;

[0083] The preparation method of the long-term heat aging resistant ABS composite material is as follows:

[0084] The components are mixed uniformly, melted and extruded through a twin-screw extruder at 200-240° C., granulated, and dried to obtain the long-term heat aging-resistant ABS composite material.

Embodiment 11~18

[0086] A long-term heat-aging resistant ABS composite material, which is different from Example 8 in that the masterbatch is the polyolefin masterbatch in Examples 2 to 9;

[0087] The rest are the same as those in Embodiment 10, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com