A kind of polypropylene composite material for air conditioner wind wheel and preparation method thereof

A composite material, polypropylene technology, applied in the field of materials, can solve the problems of low impact strength, large shrinkage, poor toughness, etc., and achieve the effect of good low temperature resistance, reduced shrinkage, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

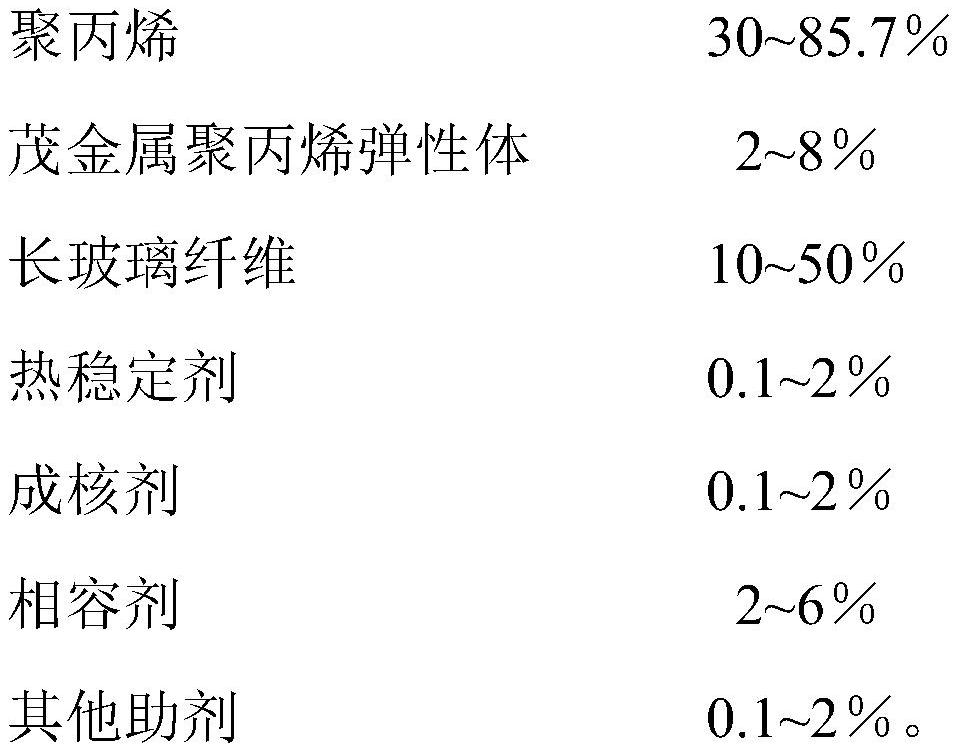

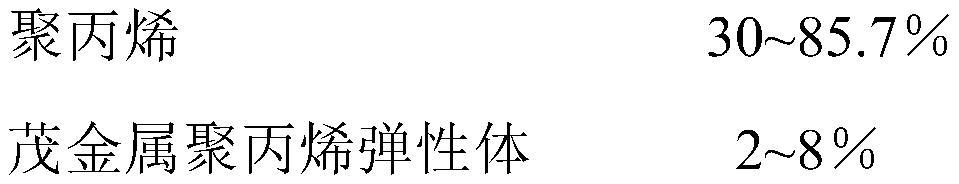

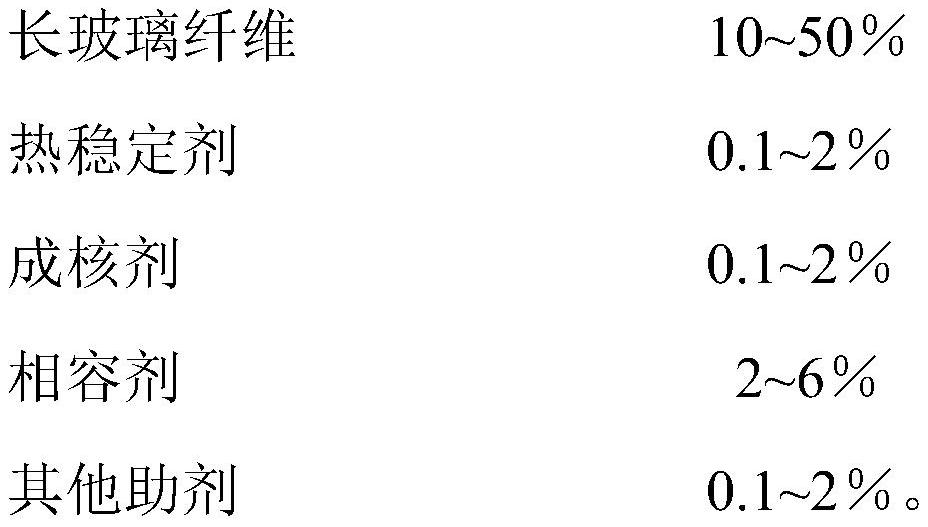

Method used

Image

Examples

preparation example Construction

[0034] Correspondingly, the embodiment of the present invention also provides a method for preparing a polypropylene composite material for an air conditioner wind wheel. The method comprises the steps of:

[0035] S01. take each component respectively by the polypropylene composite material that above-mentioned a kind of air-conditioning wind wheel is used;

[0036] S02. Put the weighed polypropylene, the metallocene polypropylene elastomer, the heat stabilizer, the auxiliary agent, the nucleating agent and the compatibilizer into a mixer and mix well , and transferred to a twin-screw extruder for melt mixing and dispersion, and output to the dipping head to obtain the first mixture;

[0037] S03. The long glass fiber is stretched and straightened by the long glass fiber auxiliary equipment machine, and evenly opened, and then enters the soaking head and is coated and mixed with the first mixture to obtain the second mixture;

[0038] S04. The second mixture is pulled out, ...

Embodiment 1

[0045] A polypropylene composite material for an air-conditioning wind wheel, the components of the polypropylene composite material are as follows: the polypropylene is selected from high-melt polypropylene M60T, the metallocene polypropylene elastomer is selected from VM6202, and the heat stabilizer is selected from phenolic thermally stable Mixture of agent 1790, phosphite heat stabilizer 168 and thioester heat stabilizer DLTDP, phenolic heat stabilizer 1790, phosphite heat stabilizer 168, thioester heat stabilizer DLTDP, additives EBS is selected, the nucleating agent is TMP-5, and the compatibilizer is maleic anhydride grafted polypropylene.

[0046] The preparation method of the polypropylene composite material is as follows: 72.7% high melting point polypropylene M60T, 3% metallocene polypropylene elastomer VM6202, 0.2% phenolic heat stabilizer 1790, 0.3% phosphite heat stabilizer 168 , 0.3% thioester heat stabilizer DLTDP, 0.3% auxiliary agent EBS, 0.2% nucleating agen...

Embodiment 2

[0048] A polypropylene composite material for an air-conditioning wind wheel, the components of the polypropylene composite material are as follows: the polypropylene is selected from high-melt polypropylene M60T, the metallocene polypropylene elastomer is selected from VM6202, and the heat stabilizer is selected from phenolic thermally stable Mixture of agent 1790, phosphite heat stabilizer 168 and thioester heat stabilizer DLTDP, phenolic heat stabilizer 1790, phosphite heat stabilizer 168, thioester heat stabilizer DLTDP, additives EBS is selected, the nucleating agent is TMP-5, and the compatibilizer is maleic anhydride grafted polypropylene.

[0049] The preparation method of the polypropylene composite material is as follows: 60.7% high melting point polypropylene M60T, 4% metallocene polypropylene elastomer VM6202, 0.2% phenolic heat stabilizer 1790, 0.3% phosphite heat stabilizer 168 , 0.3% thioester heat stabilizer DLTDP, 0.3% auxiliary agent EBS, 0.2% nucleating agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com