A kind of halogen-free anti-aging epoxy resin composition and the method for preparing covering film with the resin composition

A technology of epoxy resin and composition, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of poor long-term aging resistance, fracture, easy cross-linking of unsaturated double bonds, etc. Effects of long-term aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

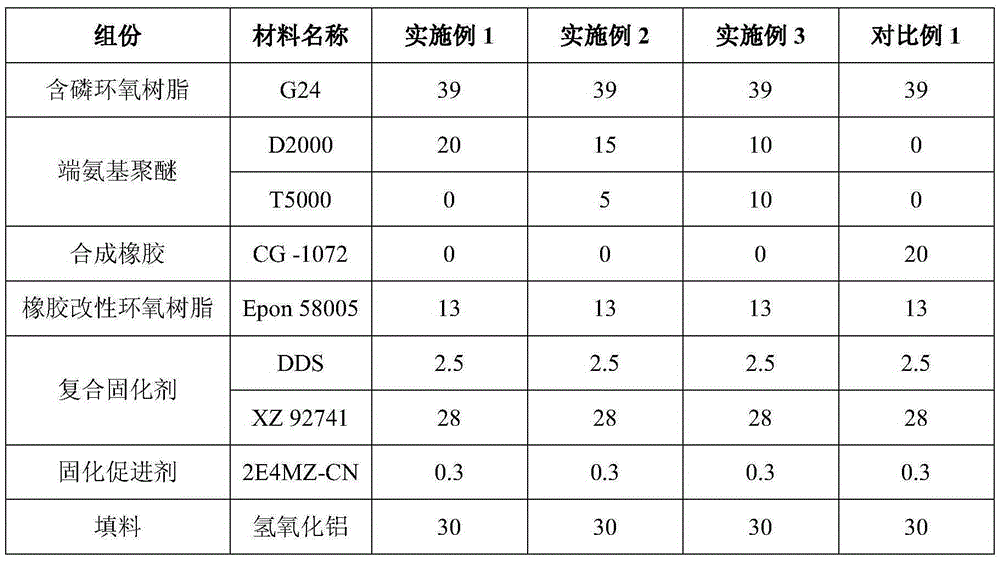

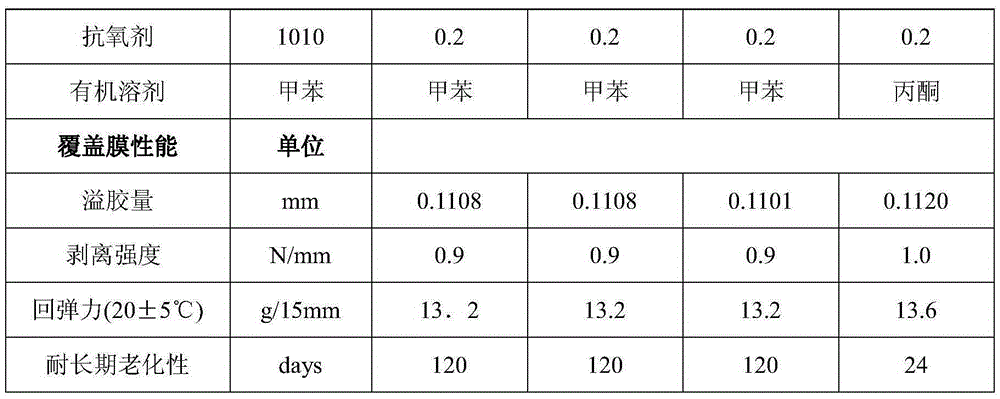

Embodiment 1

[0028]A halogen-free aging-resistant epoxy resin composition, including the following components by weight: phosphorus-containing epoxy resin (product model G-24, epoxy equivalent 340g / eq, phosphorus content 2.4% by mass, Jiangshan Jianghuan Chemical Industry Co., Ltd.) 39 parts by weight; aliphatic amino-terminated polyether D-2000 (manufactured by Huntsman Chemical Co.) 20 parts by weight; rubber-modified epoxy resin (product model EponResin58005, elastomer content 40% by weight, Manufactured by Hexion Specialty Chemicals, Inc.) 13 parts by weight; phosphorus-containing phenolic resin (product model XZ92741, phosphorus content 9% by mass, manufactured by Dow Chemical Company) 28 parts by weight; diaminodiphenyl sulfone 2.5 parts by weight; 1-cyanoethyl-2 ethyl 0.3 parts by weight of base-4 methylimidazole (2E4MZ-CN); 30.0 parts by weight of aluminum hydroxide (average particle size 1 to 5 μm, purity 99% or more); 0.20 parts by weight of antioxidant (commercial model 1010, man...

Embodiment 2

[0031] A halogen-free aging-resistant epoxy resin composition, including the following components by weight: phosphorus-containing epoxy resin (product model G-24, epoxy equivalent 340g / eq, phosphorus content 2.4% by mass, Jiangshan Jianghuan Chemical Industry Co., Ltd.) 39 parts by weight; aliphatic amino-terminated polyether D-2000 (molecular weight 2000, linear bifunctional amino polyether, manufactured by Huntsman Chemical Company) 15 parts by weight; amino-terminated polyether T-5000 ( Molecular weight 5000, trifunctional amino polyether, manufactured by Huntsman Chemical Company) 5 parts by weight; rubber modified epoxy resin (product model EponResin58005, elastomer content 40% by weight, manufactured by Hexion Specialty Chemicals, Inc.) 13 parts by weight; Phosphorus-containing phenolic resin (product model XZ92741, phosphorus content 9% by mass, manufactured by Dow Chemical Company) 28 parts by weight; diaminodiphenylsulfone 2.5 parts by weight; 1-cyanoethyl-2ethyl-4 me...

Embodiment 3

[0034] A halogen-free aging-resistant epoxy resin composition, including the following components by weight: phosphorus-containing epoxy resin (product model G-24, epoxy equivalent 340g / eq, phosphorus content 2.4% by mass, Jiangshan Jianghuan Chemical Industry Co., Ltd.) 39 parts by weight; aliphatic amino-terminated polyether D-2000 (molecular weight 2000, linear bifunctional amino polyether, manufactured by Huntsman Chemical Company) 10 parts by weight; amino-terminated polyether T-5000 ( Molecular weight 5000, trifunctional amino polyether, manufactured by Huntsman Chemical Company) 10 parts by weight; rubber modified epoxy resin (product model EponResin58005, elastomer content 40% by weight, manufactured by Hexion Specialty Chemicals, Inc.) 13 parts by weight; Phosphorus-containing phenolic resin (product model XZ92741, phosphorus content 9% by mass, manufactured by Dow Chemical Company) 28 parts by weight; diaminodiphenylsulfone 2.5 parts by weight; 1-cyanoethyl-2ethyl-4 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com