Irradiation crosslinking low-smoke halogen-free flame-retardant insulating material for thin-wall ship cable as well as preparation method and application thereof

A technology for flame-retardant insulating materials and ships, which is applied in the field of irradiation cross-linked low-smoke halogen-free flame-retardant insulating materials and their preparation, which can solve the problems of poor scratching performance and heat aging performance of insulating materials, and achieve processing Good performance, excellent scratch resistance, excellent electrical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 6

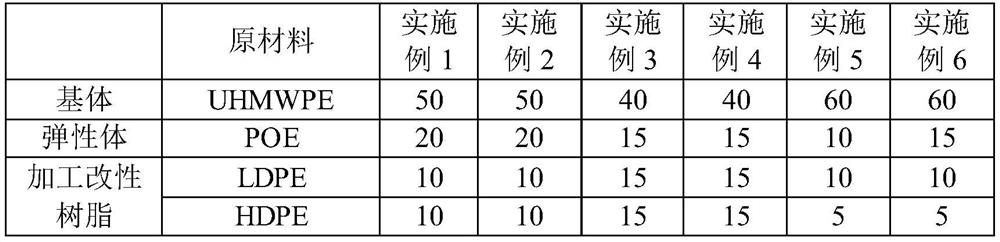

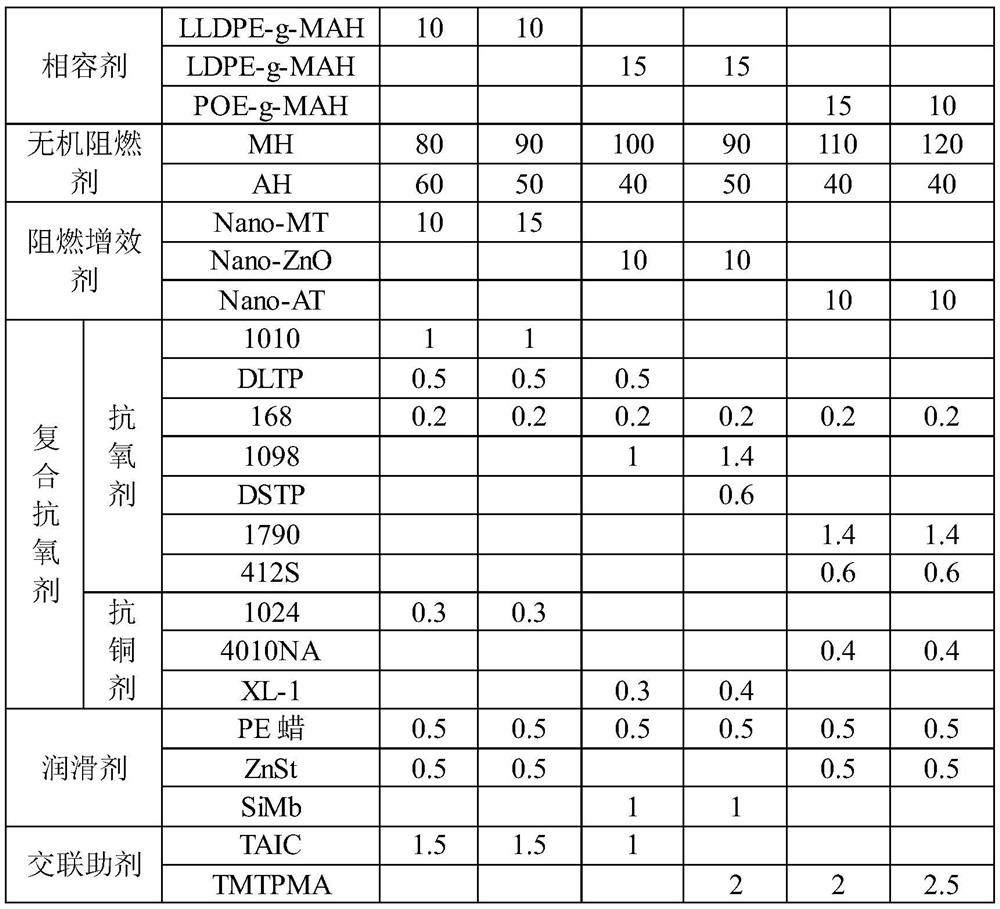

[0037] See Table 1 for the formulation of the irradiation cross-linked low-smoke halogen-free flame-retardant insulating material used in the thin-walled ship cables of Examples 1 to 6. English abbreviation or the implication of trade mark in following embodiment:

[0038] UHMWPE ultra-high molecular weight polyethylene;

[0039] POE ethylene-octene copolymer;

[0040] LDPE low-density polyethylene, HDPE high-density polyethylene; melt index is 20g / 10min~50g / 10min.

[0041] LLDPE-g-MAH linear low density polyethylene grafted with maleic anhydride,

[0042] LDPE-g-MAH low density polyethylene grafted maleic anhydride,

[0043] POE-g-MAH ethylene-octene copolymer grafted with maleic anhydride;

[0044] MH magnesium hydroxide, AH aluminum hydroxide;

[0045] Nano-MT nano montmorillonite, Nano-ZnO nano zinc oxide, Nano-AT nano attapulgite;

[0046] 1010 Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester,

[0047] DLTP dilauryl thiodipropionate, ...

Embodiment 7

[0068] The preparation method of the radiation cross-linked low-smoke halogen-free flame-retardant insulating material for the thin-walled ship cable of the above embodiment is as follows: ultra-high molecular weight polyethylene, polyolefin elastomer, processing modified resin, compatibilizer, Inorganic flame retardants, flame retardant synergists, composite antioxidants, lubricants and cross-linking aids are prepared according to the proportions of the examples in Table 1, then put into a high-speed mixer for premixing, and stir at room temperature Mix evenly for 3-5 minutes, then add the internal mixer for internal mixing to obtain the masterbatch, and add the twin-screw extruder through the double-cone forced feeder to extrude and granulate. The section is 190°C~200°C, the melting section is 180°C~190°C, and the head is 170°C~180°C.

[0069] The preparation method of the insulating material of Comparative Examples 1-3 is the same as that of this embodiment.

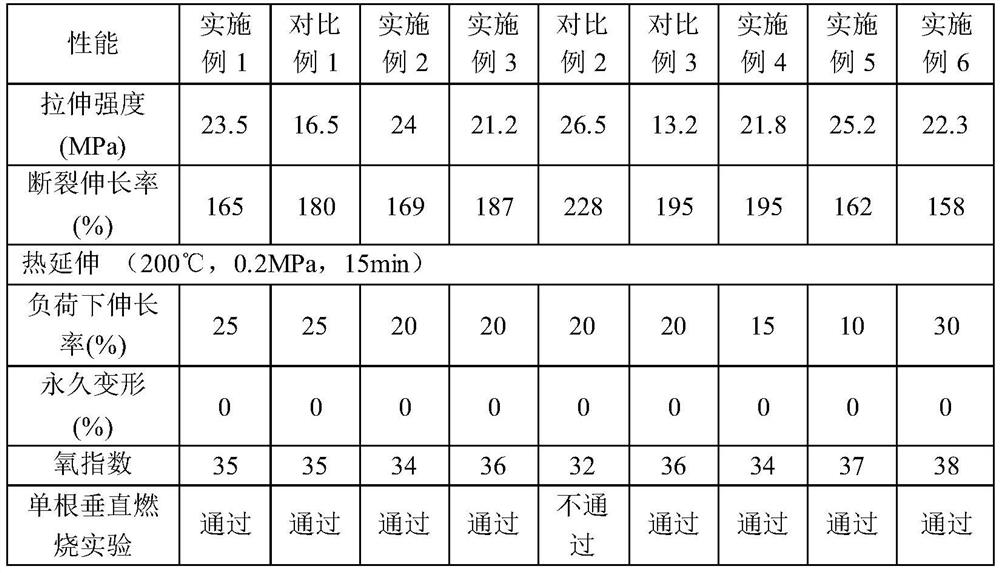

Embodiment 8

[0071] According to the preparation method in Example 7, the irradiation cross-linked low-smoke halogen-free flame-retardant insulation material for the thin-walled ship cables corresponding to the proportions of Examples 1-6 was extruded by a single-screw extruder and coated on the conductor The outer layer is used as an insulating layer, and after being irradiated and cross-linked by an electron accelerator (the radiation dose is controlled by thermal extension, and the thermal extension is controlled within 100%), thin-walled ship cables with different ratios of insulating layers (or insulation Core).

[0072] The method for preparing cables using the insulating materials of Comparative Examples 1-3 as the insulating layer is the same as that of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com