Magnetic slurry capsule system for repairing concrete cracks and construction process

A concrete and concrete structure technology, which is applied in the field of crack repair, can solve the problems of shortening the service life of building structures, harsh living conditions for microorganisms, and short-term repair, and achieve the effect of untimely repair, dense molecular structure, and small volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

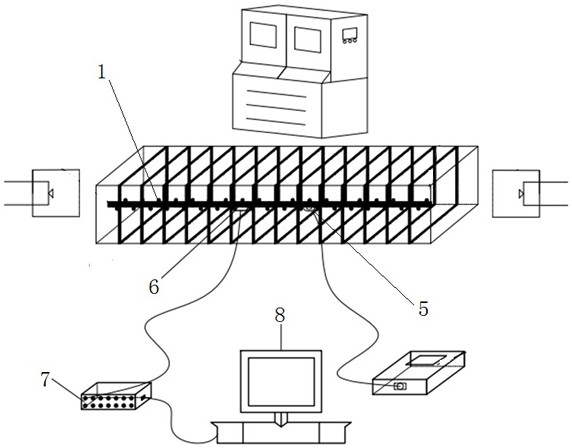

Method used

Image

Examples

Embodiment Construction

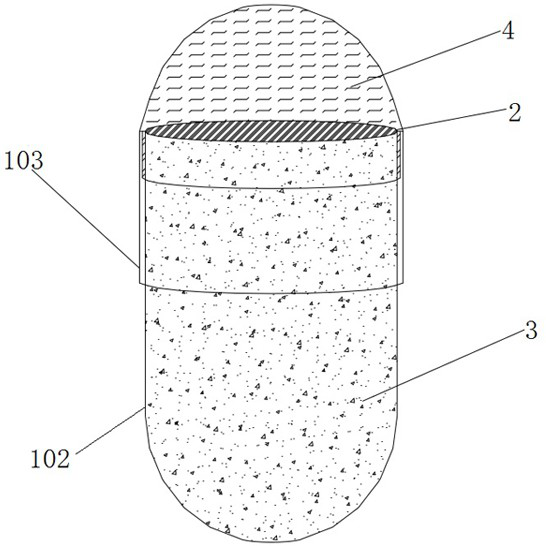

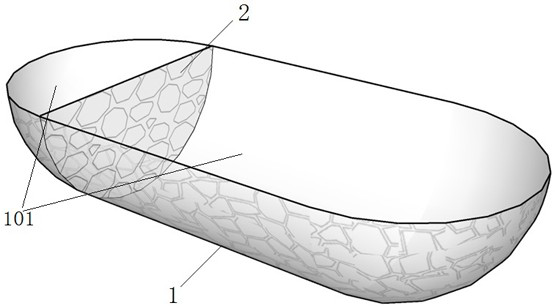

[0033] like figure 1 As shown, a magnetic slurry capsule system for repairing concrete cracks includes a repairing capsule, the repairing capsule includes a capsule shell 1, and a separator 2 is arranged in the capsule shell 1 to separate the capsule shell 1 into two cavities 101, two The space size ratio of the cavity 101 is 4:1, and the magnetic slurry 3 and the curing agent 4 are respectively arranged in the cavity 101 .

[0034] The capsule shell 1 includes a first half-shell 102 and a second half-shell 103, the separator 2 and the second half-shell 103 are sequentially buckled on the open end of the first half-shell 102, and the separator 2 is a cover-like structure.

[0035] In specific use, the capsule shell 1 is designed with a double locking system. First, the magnetic slurry 3 is placed in the first half shell 102, and the separator 2 is set for pre-locking, and the curing agent 4 is placed in the second half shell 103. The second half shell 103 and the first half s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com