Large-span single-arch subway station, large-section tunnel, underground structure and construction method thereof

A technology for subway stations and stations, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of large waste of initial support, small application ratio of underground excavation stations, and difficult organization and coordination, so as to reduce the number of transitions and the number of configurations, speeding up the construction progress of the whole line, and exerting the effect of shield operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

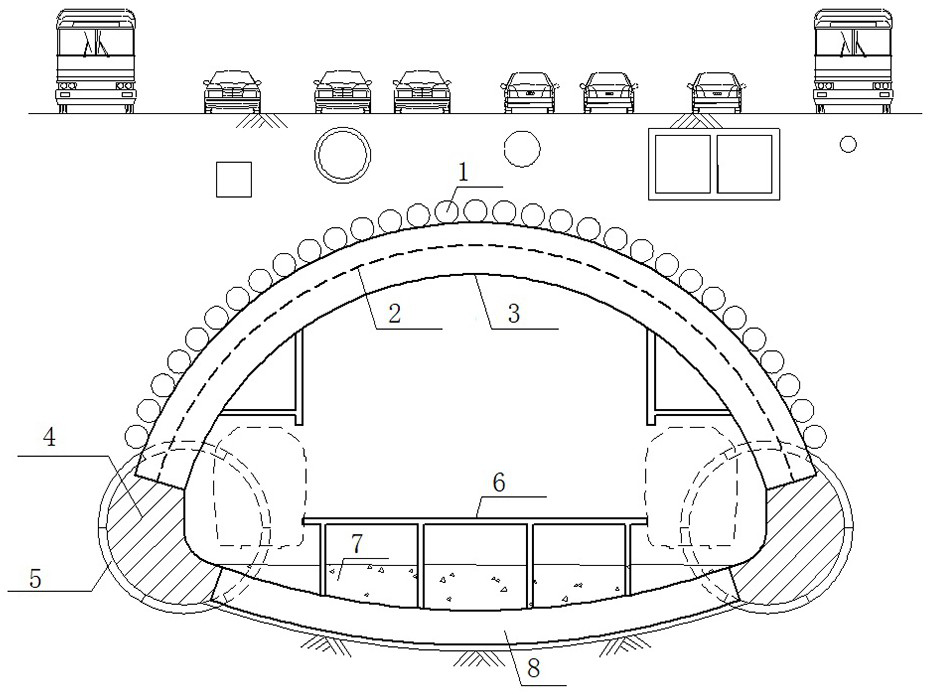

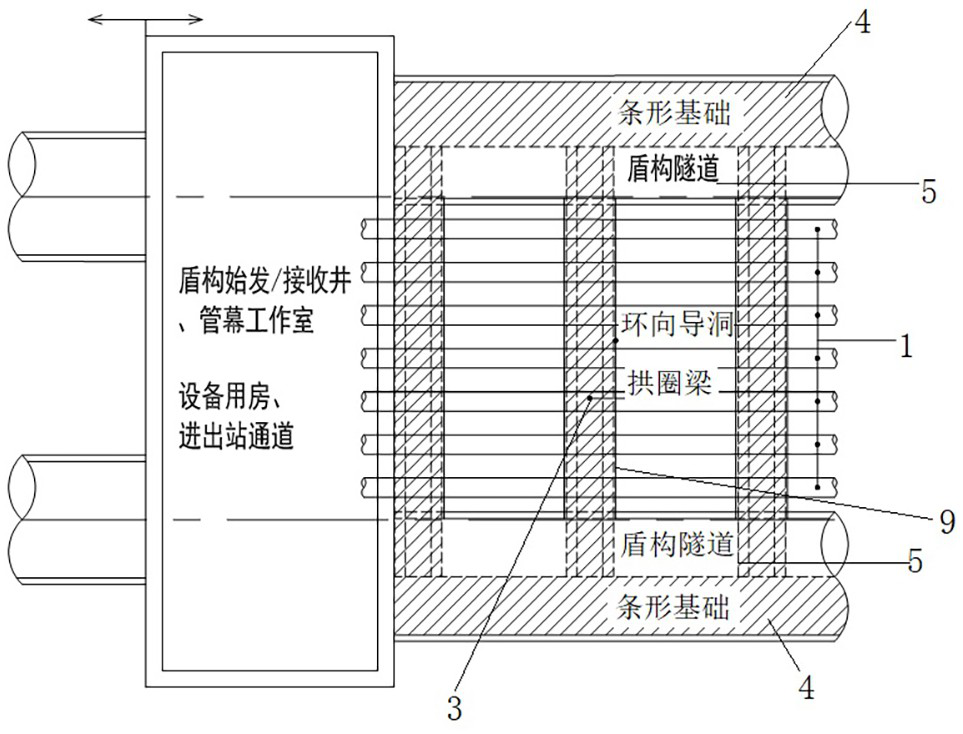

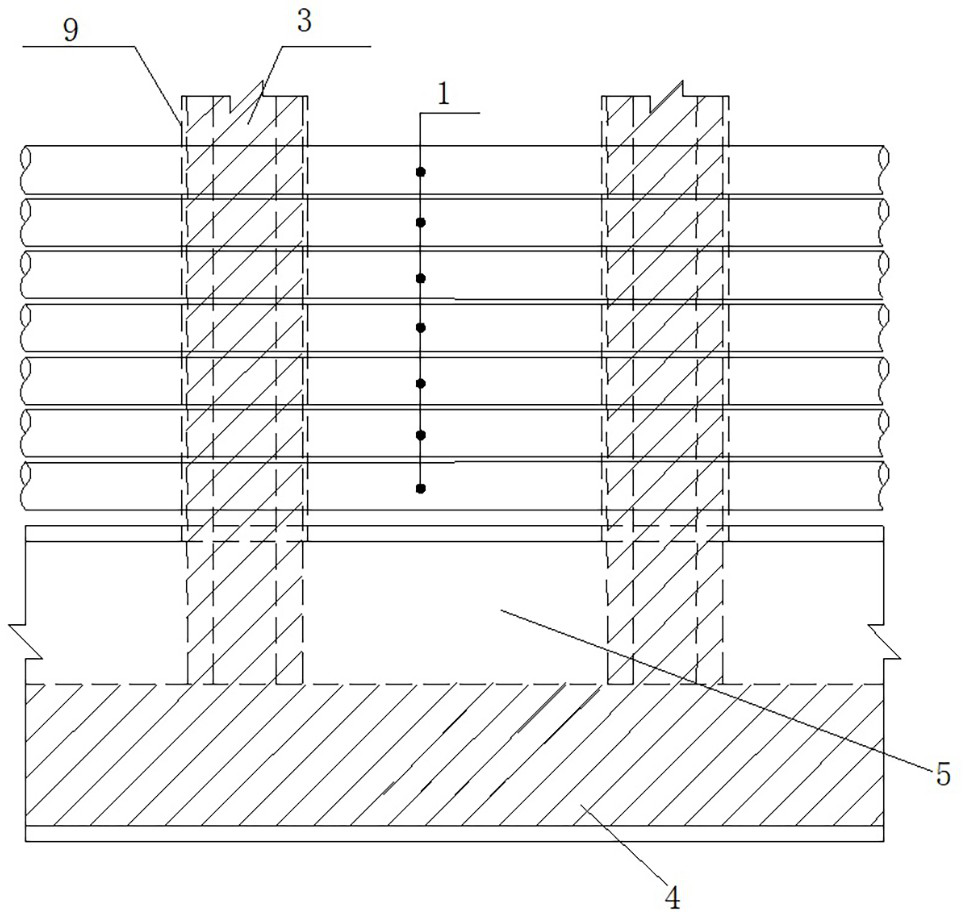

[0060] Take a standard-span single-arch single-story subway station as an example, see Figure 1~Figure 5 , the station adopts the single-arch type. The large-span single-arch subway station includes: tube curtain 1, arch ring plate 2, arch ring beam 3, strip foundation 4, shield tunnel 5, platform plate 6, backfill layer 7, The arch 8, the ring guide hole 9 and the middle plate 10.

[0061] The specific implementation is as follows:

[0062] like image 3 and Image 6 As shown in the figure, a shaft structure is set at the end of the station. After the construction of the section shield is completed, after the shaft is received, it will be translated and two longitudinal shield tunnels will be constructed along the arch foot of the station. After the shield tunnel continues the construction section, the tunnel is supported by segment lining. The longitudinal tube curtain 1 shall be constructed along the outer contour of the station arch ring, and the diameter of the tube ...

Embodiment 2

[0069] like Figure 12 As shown in the figure, the curvature of the arch ring can be adjusted according to the needs, the station can be made into a double layer, the platform layer of the double-layer station can be set with a single column or without a column, and the bottom surface of the middle plate 10 of the station without a column can be arched into a variable cross-section form. 10 The thickness is the largest on both sides and thins towards the middle.

[0070] Figure 1~Figure 12 It is a typical example of the construction method of the present invention, and these embodiments are only used to further illustrate the details and effects of the method of the present invention, and do not limit the present invention. Ordinary technicians in the industry can carry out corresponding derivation according to the external environmental conditions of the project, combined with the engineering geological and hydrogeological conditions in the implementation of the project.

...

Embodiment 3

[0073] like Figure 13 As shown, the method for constructing a large-span single-arch subway station by underground excavation provided by the embodiment of the present invention includes:

[0074] S101, two longitudinal shield tunnels 5 are constructed along the arch foot of the station by shield, and the shield tunnel 5 is supported by segment lining; the longitudinal pipe curtain 1 is constructed along the outer contour of the arch ring beam 3 of the station, and the pipe curtain 1 is poured inside Self-compacting concrete.

[0075] S102, cast the reinforced concrete strip foundation 4 in the shield tunnel 5 through the length, and reserve the connecting bars of the arch ring plate 2, the arch ring beam 3 and the inverted arch 8 on the strip foundation 4.

[0076] S103, excavate annular guide holes 9 in the shield tunnel 5 vertically and closely adhere to the longitudinal pipe curtain 1 at intervals, and construct an arch ring beam 3 in the annular guide hole 9, and the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com