Hydraulic cylinder system, hydraulic walking beam and working method of hydraulic walking beam

A hydraulic cylinder and hydraulic source technology, applied in the field of hydraulic cylinders, can solve problems such as unbalanced power output of hydraulic pump stations, heating of hydraulic sources, and easy failure of hydraulic sources, etc., to improve energy recovery effects, meet working conditions, and maintain good performance. The effect of the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

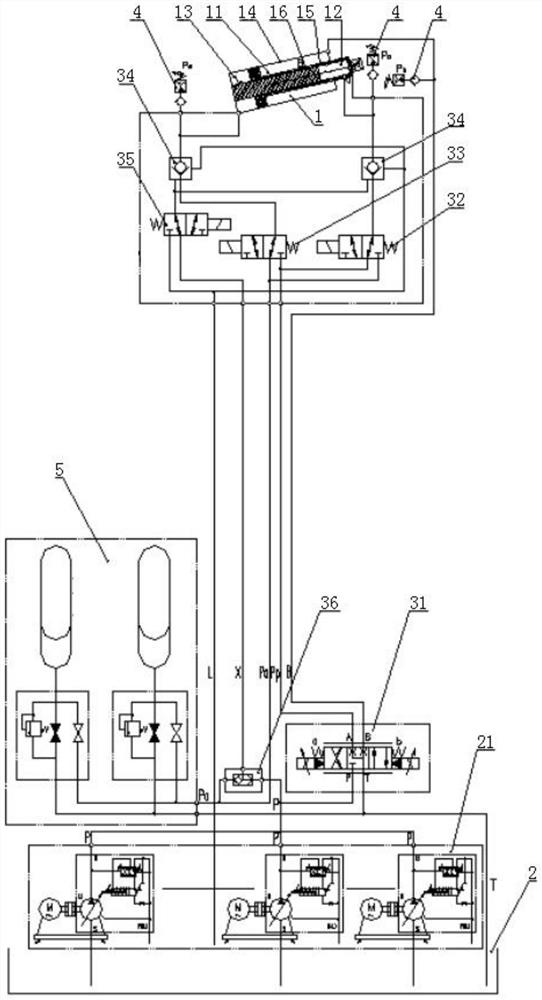

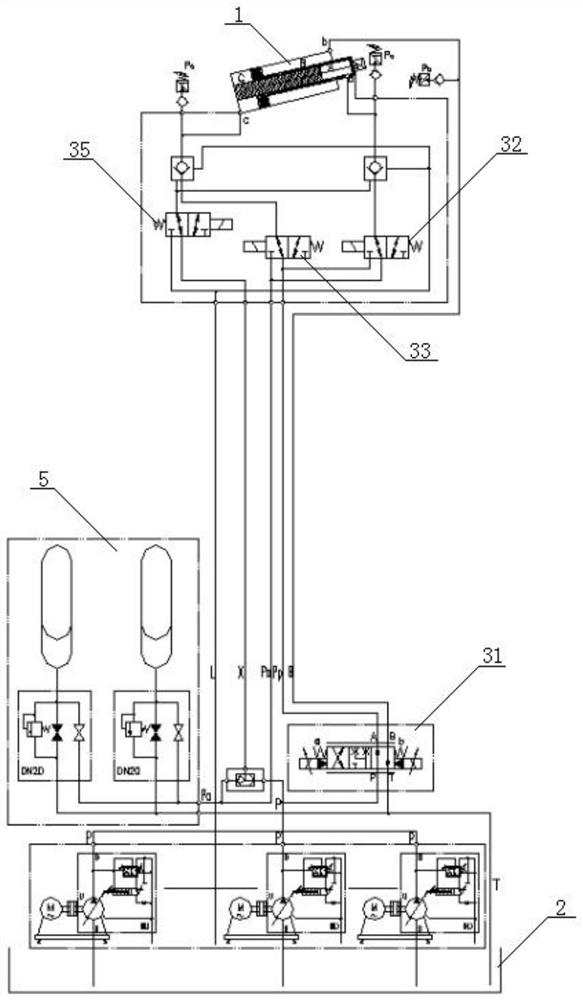

[0034] like figure 1 , Figure 3-Figure 6 , the embodiment of the present invention provides a hydraulic cylinder system, including a hydraulic cylinder 1, an accumulator 5, a valve control mechanism, and a hydraulic source 2 with an oil supply port and an oil return port.

[0035] like figure 1 , Figure 3-Figure 6 , the hydraulic cylinder 1 includes a cylinder barrel 14, a piston rod 15, and a piston connected to the piston rod 15 and slidably arranged in the cylinder barrel 14. The cylinder barrel 14 is provided with a guide column 16, and the The piston rod 15 is a hollow piece and is sleeved on the guide post 16 . The piston, the piston rod 15 and the cylinder 14 cooperate to form a rod cavity 11 , and the piston rod 15 and the The first rodless cavity 12 is formed by the guide column 16 , and the second rodless cavity 13 is formed by the piston, the guide column 16 and the cylinder 14 . Preferably, the above-mentioned piston is connected to the end of the piston rod ...

Embodiment 2

[0046] An embodiment of the present invention provides a hydraulic walking beam, comprising a walking beam body, a lifting hydraulic cylinder for driving the walking beam body to lift and lower, and a translation hydraulic cylinder for driving the walking beam body to translate. The lifting hydraulic cylinder adopts the hydraulic cylinder system provided in the first embodiment.

[0047] The present invention also relates to the working method of the above-mentioned hydraulic walking beam, and the working method includes:

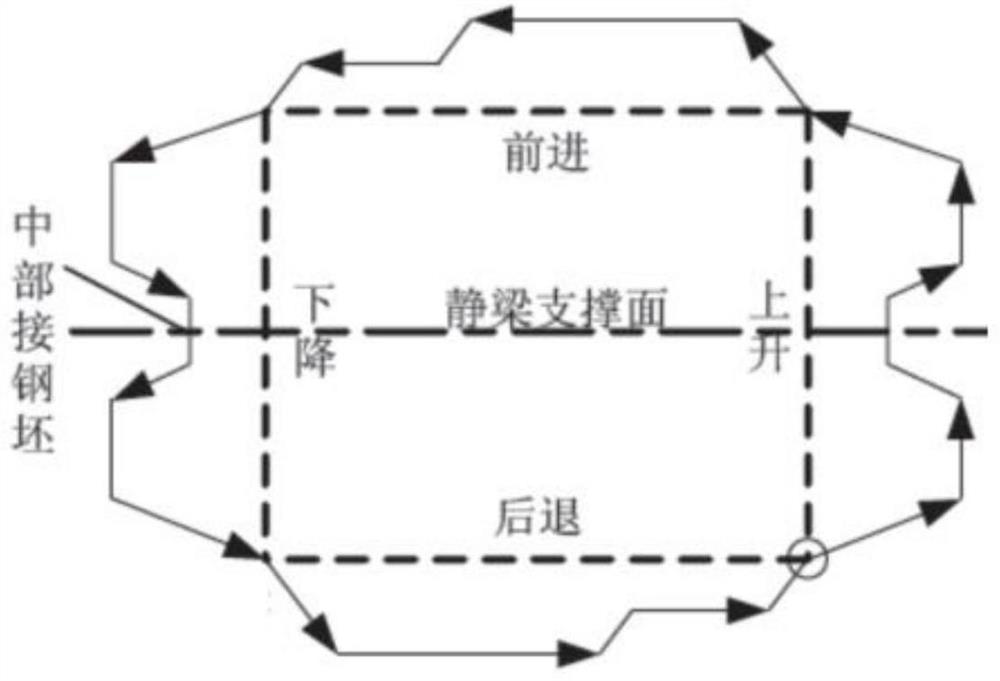

[0048] Taking the support surface of the static beam as the boundary, the actions of the walking beam above the support surface of the static beam are defined as full-load up and full-load down, respectively, and the actions of the walking beam below the static beam support surface are respectively no-load down and no-load up;

[0049] No-load ascent process: through the valve control in the hydraulic cylinder system, the accumulator 5 supplies pressure oil...

Embodiment 3

[0065] Combine the following Figure 2 to Figure 6 , for the above-mentioned specific hydraulic walking beam, its working process is roughly described as follows:

[0066] The operation of the billet in the furnace is completed by the ascending → forward → descending → backward of the walking beam body. During the rising and descending process of the billet, such as figure 2 , taking the support surface of the static beam as the boundary, the actions above the support surface of the static beam are full-load rise and full-load descent, respectively, and the actions below the static beam support surface are no-load descent and no-load rise, respectively.

[0067] No-load ascent process: such as image 3 , the second directional control valve 32 and the third directional control valve 33 are in the left position; the first directional control valve 31 is in the right position; the reversing control valve 35 is in the left position, and the two one-way valves 34 are in the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com