High-rotating-speed and high-power hydraulic coupler speed regulating device capable of sucking back hydraulic oil

A technology of hydraulic coupling and speed regulating device, which is applied in the direction of fluid pressure actuating device, clutch, fluid clutch, etc., can solve the problem of lack of hydraulic oil suction mechanism, affecting the service life of hydraulic coupling, and shortening the internal key components. Service life and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

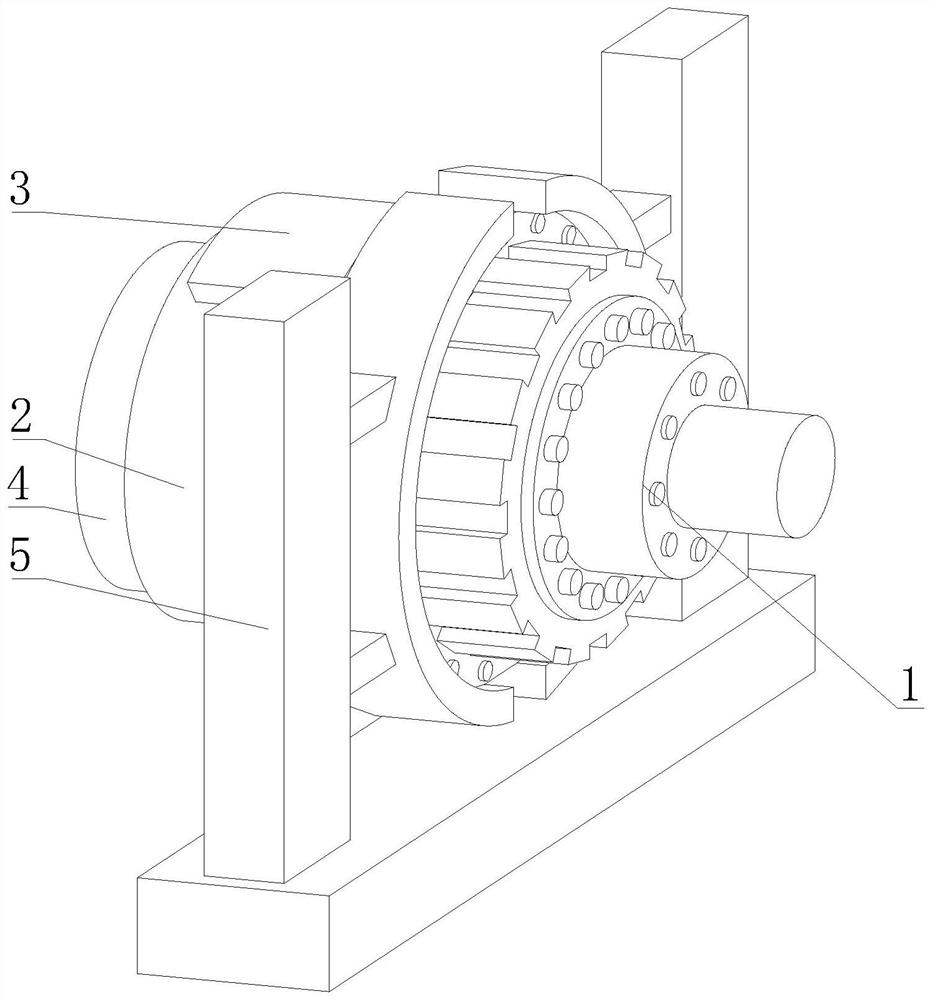

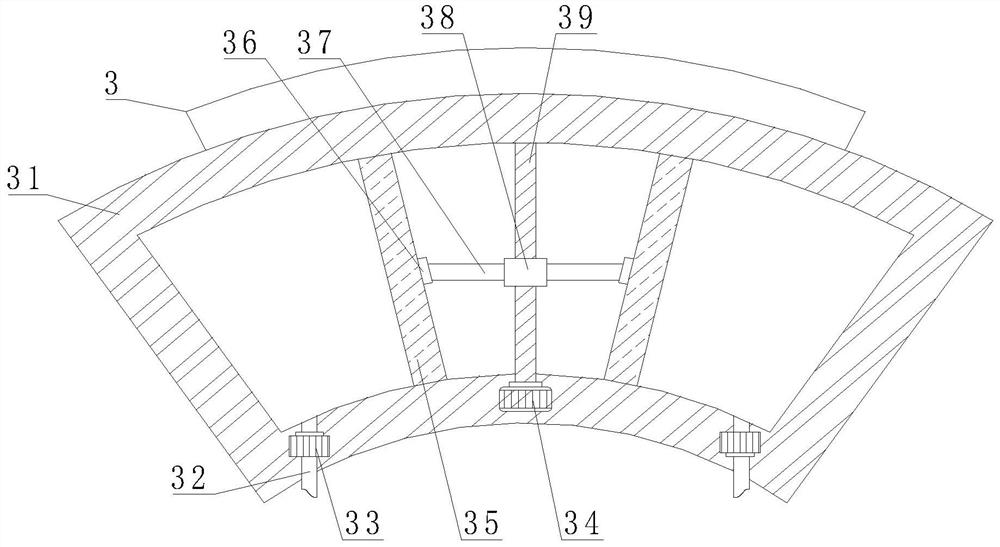

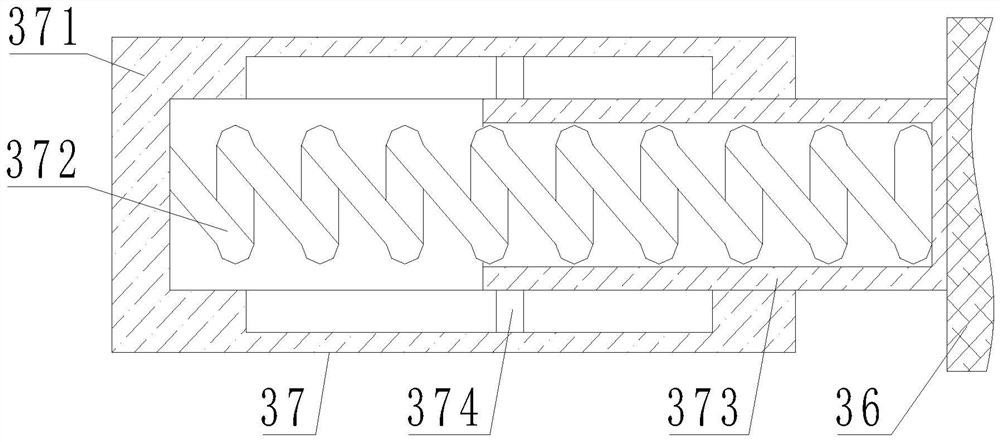

[0041] like Figure 1-7As shown in the figure, the present invention provides a high-speed and high-power hydraulic coupling speed regulating device that can suck back hydraulic oil, including a hydraulic coupling 1, and a speed regulating device 2 is arranged on the left side of the hydraulic coupling 1. The top of the speed device 2 is provided with a back suction mechanism 3, the left side of the speed control device 2 is provided with a cooling mechanism 4, the surface of the hydraulic coupler 1 is provided with a limit mechanism 5, and the back suction mechanism 3 includes a back suction shell 31. A filter plate 35 is fixedly connected to the inner wall of the casing 31 , a No. 1 motor 34 is arranged inside the suction casing 31 , an output end of the No. 1 motor 34 is fixedly connected to a No. 1 threaded rod 39 , and the top of the No. 1 threaded rod 39 is connected to the suction casing 31 . The top of the inner wall is movably connected, the surface of the No. 1 threa...

Embodiment 2

[0044] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the cooling mechanism 4 includes a cooling casing 41, the top of the cooling casing 41 is provided with a water tank 42, and the surface of the water tank 42 is provided with a cooling sheet 43, The bottom of the water tank 42 is fixedly connected with a water pipe 45, the surface of the water pipe 45 is provided with a water pump 44, the bottom of the water pipe 45 extends to the inner cavity of the cooling shell 41 and is provided with a water distributor 46, and the bottom of the inner wall of the cooling shell 41 is fixedly connected with a water storage tank 491 A return pipe 492 is fixedly connected to the interior of the water storage tank 491, and the other end of the return pipe 492 extends to the interior of the water tank 42. The surface of the return pipe 492 is provided with a return water pump 493 outside the cooling shell 41. The bottom...

Embodiment 3

[0047] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the limiting mechanism 5 includes a shock-absorbing disk 57, and the shock-absorbing disk 57 includes an extrusion shell 571, and the inner wall of the extrusion shell 571 is fixedly connected The limit rod 572 is movably sleeved with a displacement plate 574 on the surface of the limit rod 572 , and a return spring 573 is fixedly connected to the surface of the displacement plate 574 and located outside the limit rod 572 . The inner wall is fixedly connected, the surface of the displacement plate 574 is fixedly connected with a connecting column 575, one end of the connecting column 575 is extended to the outside of the extrusion shell 571 and is fixedly connected with an elastic plate 576, and the surface of the extrusion shell 571 is fixedly connected with a fixed column 56, fixed The other end of the column 56 is fixedly connected with a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com