High-rate lithium iron phosphate positive electrode material, preparation method thereof, positive electrode of high-rate lithium iron phosphate positive electrode material and battery

A technology of lithium iron phosphate and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low temperature and rate performance defects, and achieve uniform primary particle size, excellent rate and low temperature performance, and low input cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Ferrous gluconate, tributyl phosphate and lithium acetate were mixed, and the mixture was uniformly stirred at a high speed of 400 r / min at 55° C. to obtain a paste. Wherein, in the ferrous gluconate, phosphate and lithium acetate, the molar ratio of Fe, P and Li is 1:1:1.04.

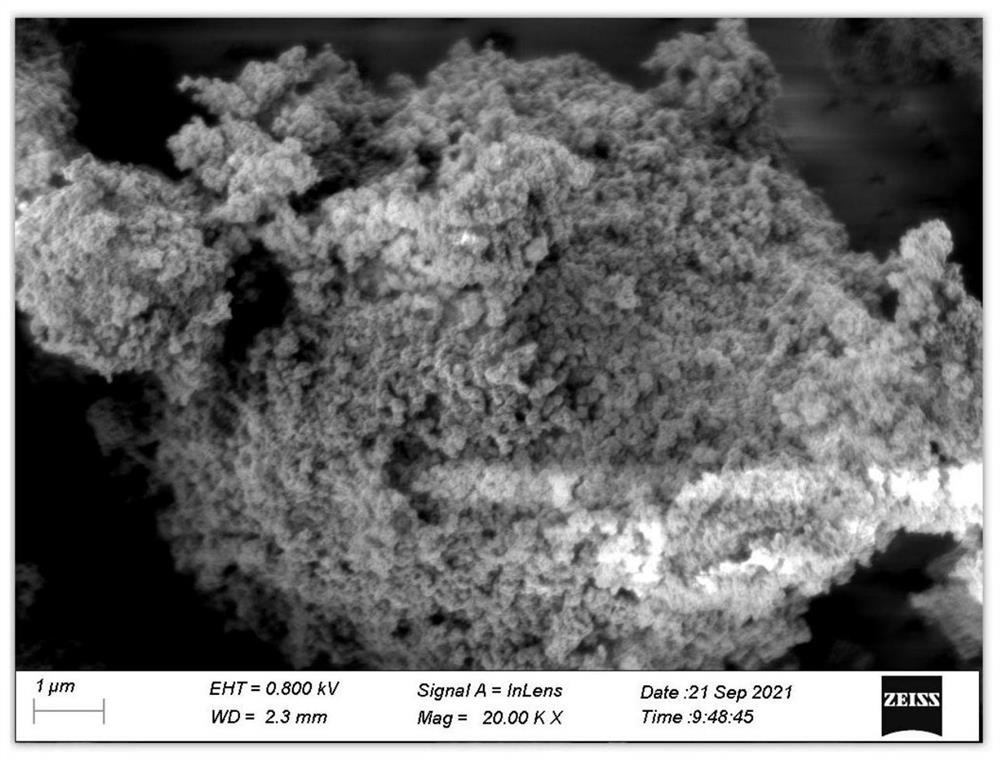

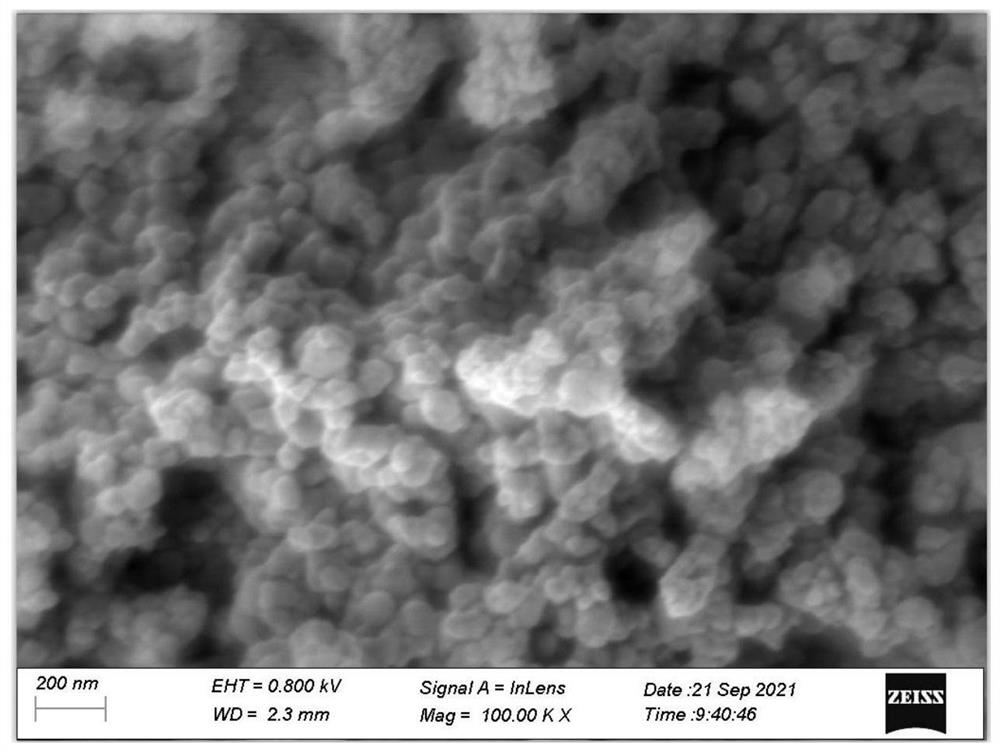

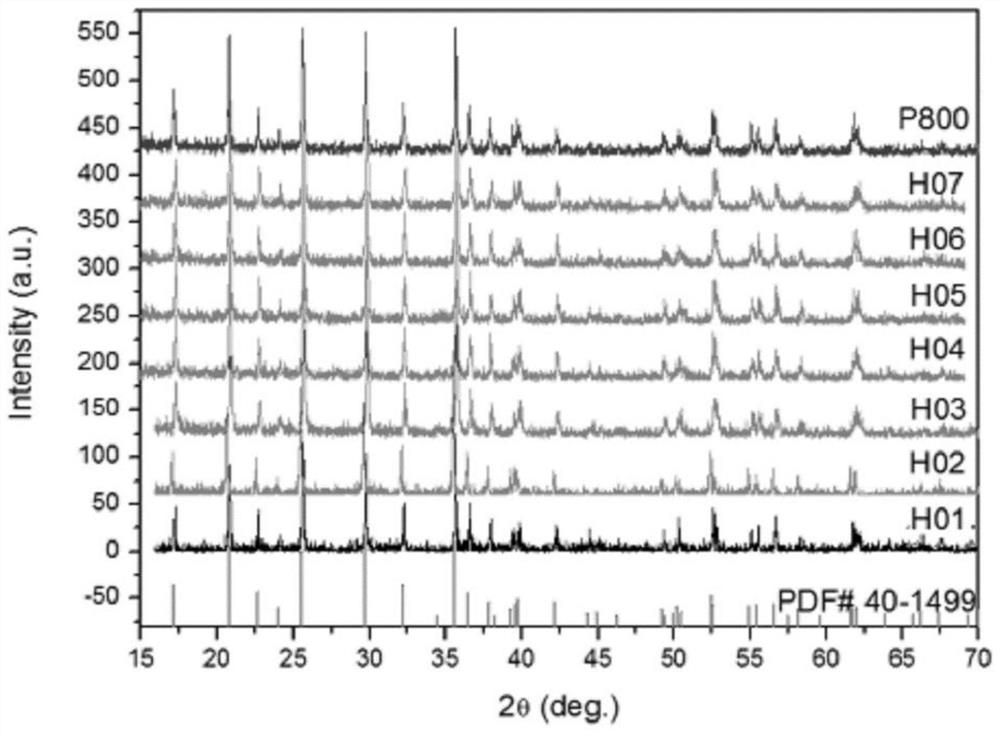

[0031] The paste obtained above is extruded and granulated and then sent into a saggar. The saggar is put into a roller furnace and calcined under nitrogen protection. The roller furnace includes a first heating section, a first heating section and a first Insulation section, second heating section, second insulation section and cooling section, the paste is heated to 320 °C at a heating rate of 65 °C / h in the first heating section, and kept at 320 °C for 3 hours in the first heating section; Continue to heat up to 690°C at a heating rate of 120°C / h in the second heating section, keep at 690°C for 5 hours in the second holding section, and then cool down to ≤60°C in the cooling section to obtain ...

Embodiment 2

[0049] Ferrous citrate, trioctyl phosphate and lithium acetate were mixed, and the mixture was uniformly stirred at a high speed of 400 r / min at 55° C. to obtain a paste. Wherein, in the ferrous citrate, trioctyl phosphate and lithium acetate, the molar ratio of Fe, P and Li is 1:1:1.07.

[0050] The paste obtained above is extruded and granulated and then sent into a saggar. The saggar is put into a roller furnace and calcined under nitrogen protection. The roller furnace includes a first heating section, a first heating section and a first In the heat preservation section, the second temperature increase section, the second heat preservation section and the cooling section, the paste is heated to 370 °C at a heating rate of 78 °C / h in the first heating section, and kept at 370 °C for 5 hours in the first heat preservation section; Continue to heat up to 790°C at a heating rate of 145°C / h in the second heating section, keep at 790°C for 10h in the second holding section, and ...

Embodiment 3

[0060] Ferrous acetate, tributyl phosphate and lithium citrate were mixed, and the mixture was uniformly stirred at a high speed of 400 r / min at 55° C. to obtain a paste. Wherein, in the ferrous gluconate, phosphate and lithium acetate, the molar ratio of Fe, P and Li is 1:1:1.05.

[0061] The paste obtained above is extruded and granulated and then sent into a saggar. The saggar is put into a roller furnace and calcined under nitrogen protection. The roller furnace includes a first heating section, a first heating section and a first In the heat preservation section, the second temperature increase section, the second heat preservation section and the cooling section, the paste is heated to 320 °C at a heating rate of 60 °C / h in the first heating section, and kept at 320 °C for 4 hours in the first heat preservation section; Continue to heat up to 690°C at a heating rate of 120°C / h in the second heating section, hold at 690°C for 4 hours in the second holding section, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com