Silica-alumina composites for hydrotreating applications

A silica and hydrotreating technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., can solve problems such as difficult to control pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Representative amorphous silica-alumina according to the present invention are used in the examples shown in Table 1, each of which is commercially available:

[0064] Table 1 - Amorphous silica-alumina used in the examples

[0065]

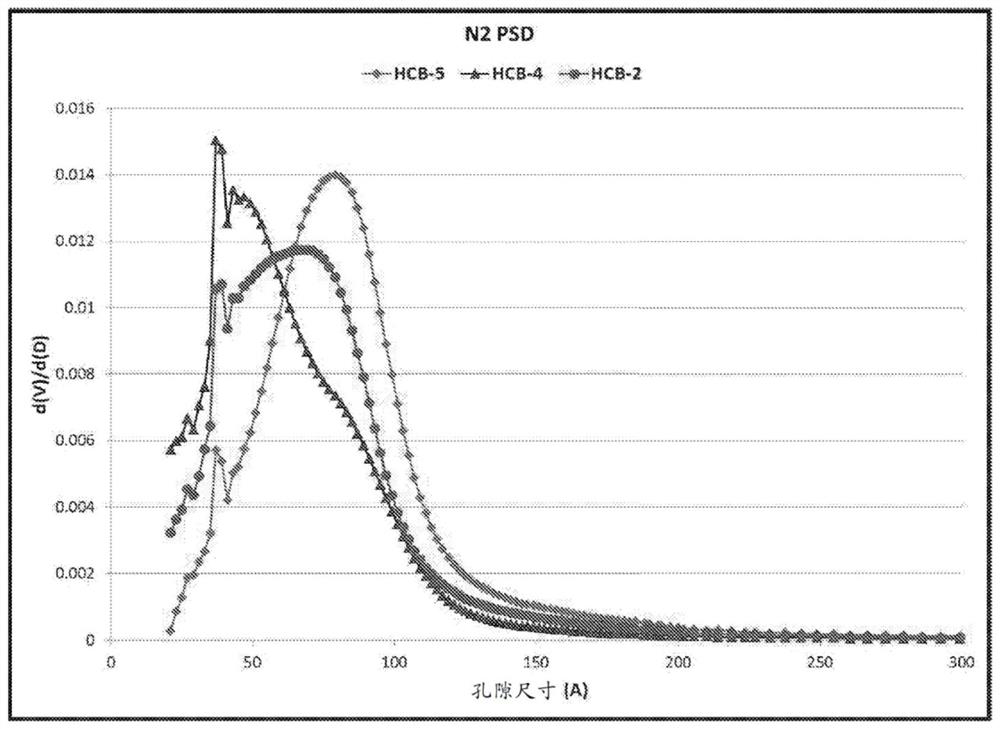

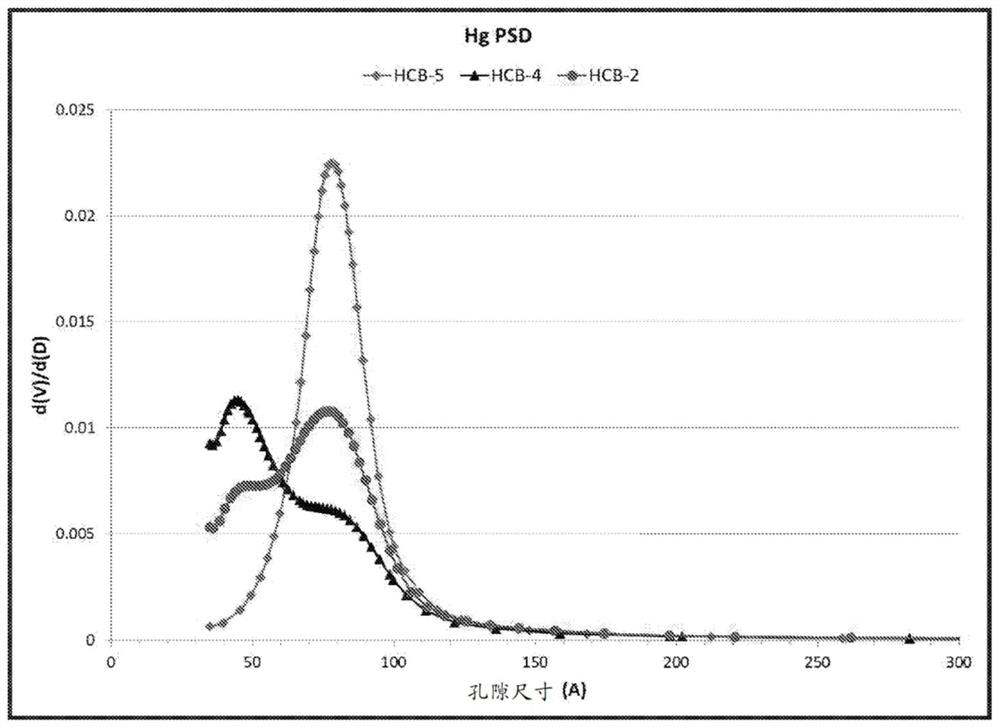

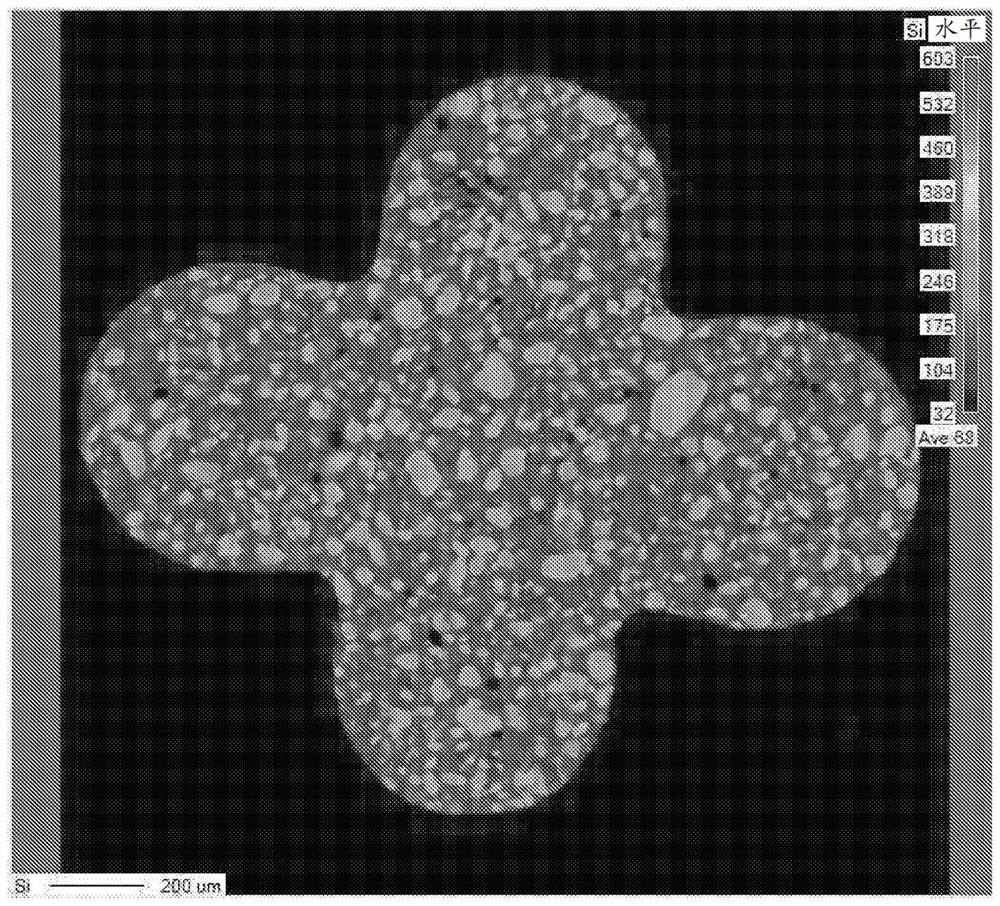

[0066] According to the present invention, the amounts of amorphous silica-alumina and nitric acid shown in Table 2 were used to prepare hydroprocessing catalyst substrates HCB-1 to HCB-7. The synthesis and characterization of each HCB sample is described below.

[0067] Table 2 - Formulations of Hydrotreating Catalyst Substrates HCB-1 to HCB-7

[0068]

[0069]

[0070] *25wt% pseudo-boehmite alumina powder balanced by 8wt% USY zeolite (SAR=50-150)

[0071] Synthesis and Characterization of Hydrotreating Catalyst Base-1 (HCB-1)

[0072] Hydrotreating catalyst substrate-1 was prepared as follows: 37 parts by weight of silica-alumina sample-1, 30 parts by weight of silica-alumina sample-5, 25 parts by weight of pseudo-boehmite a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com