Production method of formula type multifunctional liquid milk

A production method and multi-functional technology, applied in the fields of milk preparations, dairy products, applications, etc., can solve the problems of large workshop space, repeated purchase of equipment, and high production costs, and achieve the benefits of equipment, saving equipment redundancy, and facilitating streamlining. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

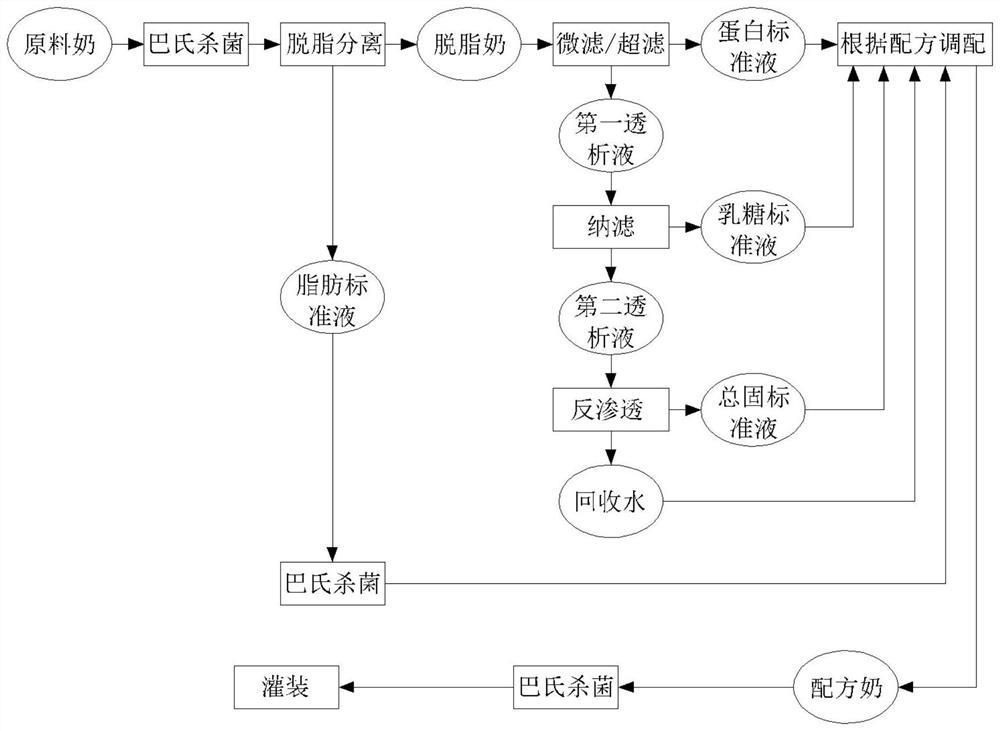

[0026] like figure 1 As shown, the present invention discloses a formula-type multifunctional liquid milk production method, which comprises the following steps:

[0027] S0: Pasteurize the raw milk. During the sterilization process, the heating temperature is above 50°C, and the heating time is 30 to 40 minutes. Sterilization treatment is carried out from the beginning of raw milk processing to ensure the hygiene of the milk source for subsequent processing, and at the same time to avoid bacteria and other residues in equipment or pipelines.

[0028] S1: Skim the sterilized raw milk by a skim separator to obtain skim milk and a fat standard solution. Fat standards can be temporarily stored in special containers for later use.

[0029] S2: Select microfiltration membrane or ultrafiltration membrane for dialysis treatment of skim milk, preferably ultrafiltration membrane, and obtain protein standard solution (ultrafiltration concentrate) and first dialysate through dialysis t...

Embodiment 2

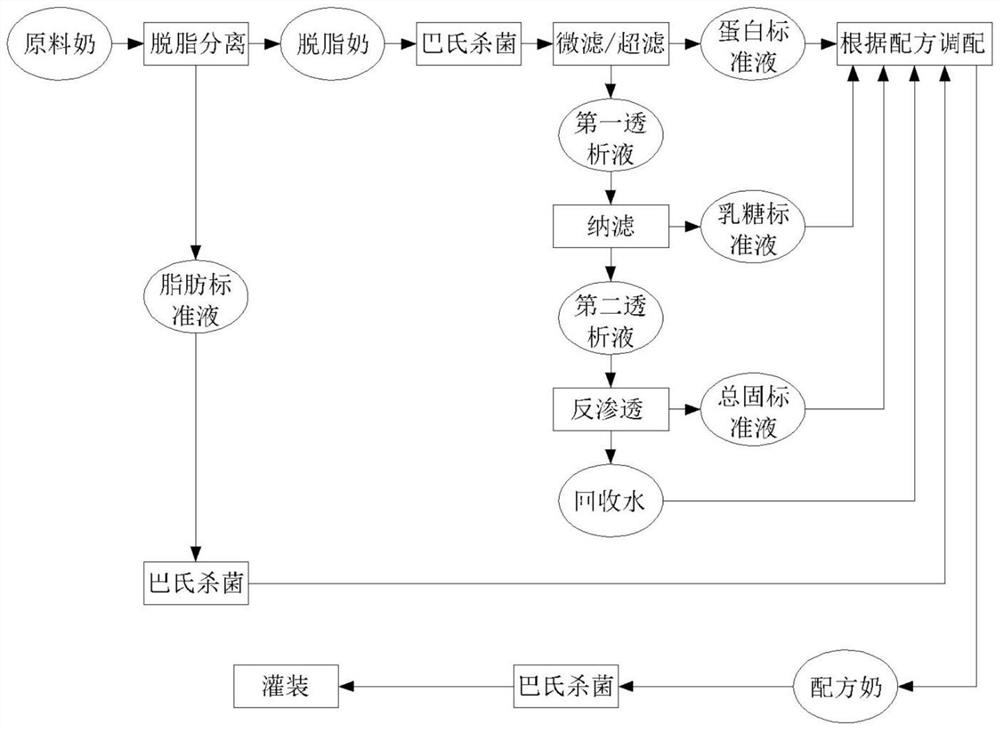

[0035] The difference between this embodiment and the first embodiment is that step S0 is removed, the raw milk is directly skimmed first, the obtained skim milk is pasteurized first (ie, step S11 ), and the sterilized skim milk is then processed in step S2 . In step S11, the heating temperature is above 50°C, and the heating time is 30-40 min.

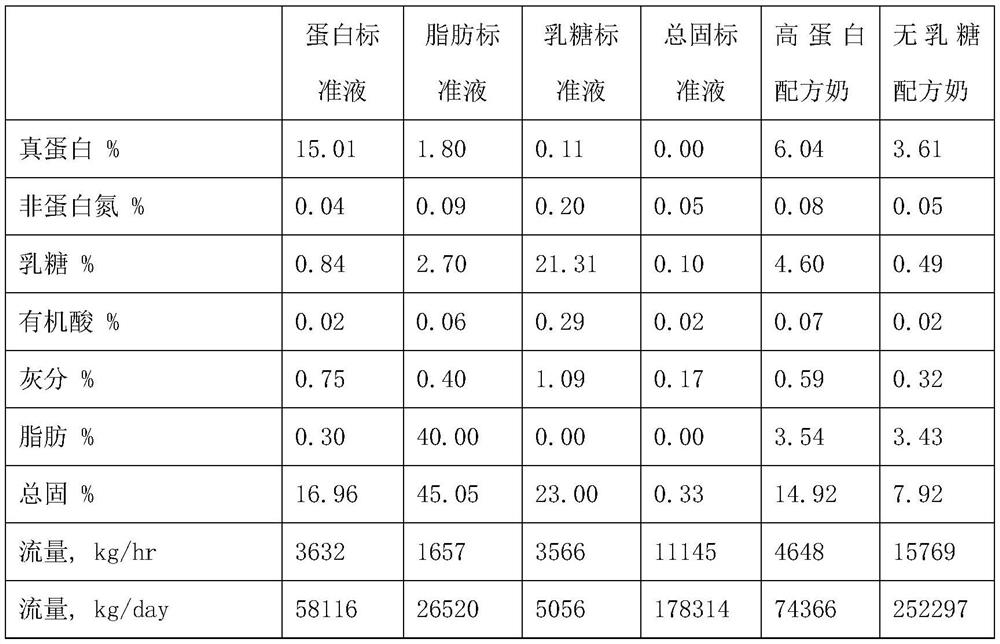

[0036] In the following, description will be given by formulating three different formulas, which are high-protein formula, lactose-free formula and high-protein yogurt. The contents of each component in the fat standard solution, protein standard solution, lactose standard solution and total solid standard solution obtained from the raw milk through the above steps are shown in Table 1 and Table 2. The composition requirements of high-protein formula milk and lactose-free formula milk, as well as the mixing ratio of fat standard solution, protein standard solution, lactose standard solution and total solid standard solution are show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com