Crystallizing tank for extracting hyodeoxycholic acid

A technology of hyodeoxycholic acid and crystallization tank, which is applied in the directions of crystallization separation, solution crystallization, separation method, etc., can solve the problems of increased preparation efficiency, reduced crystallization steps, complicated extraction operation steps, etc., and achieves convenient extraction and reduced crystallization extraction. The effect of the steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

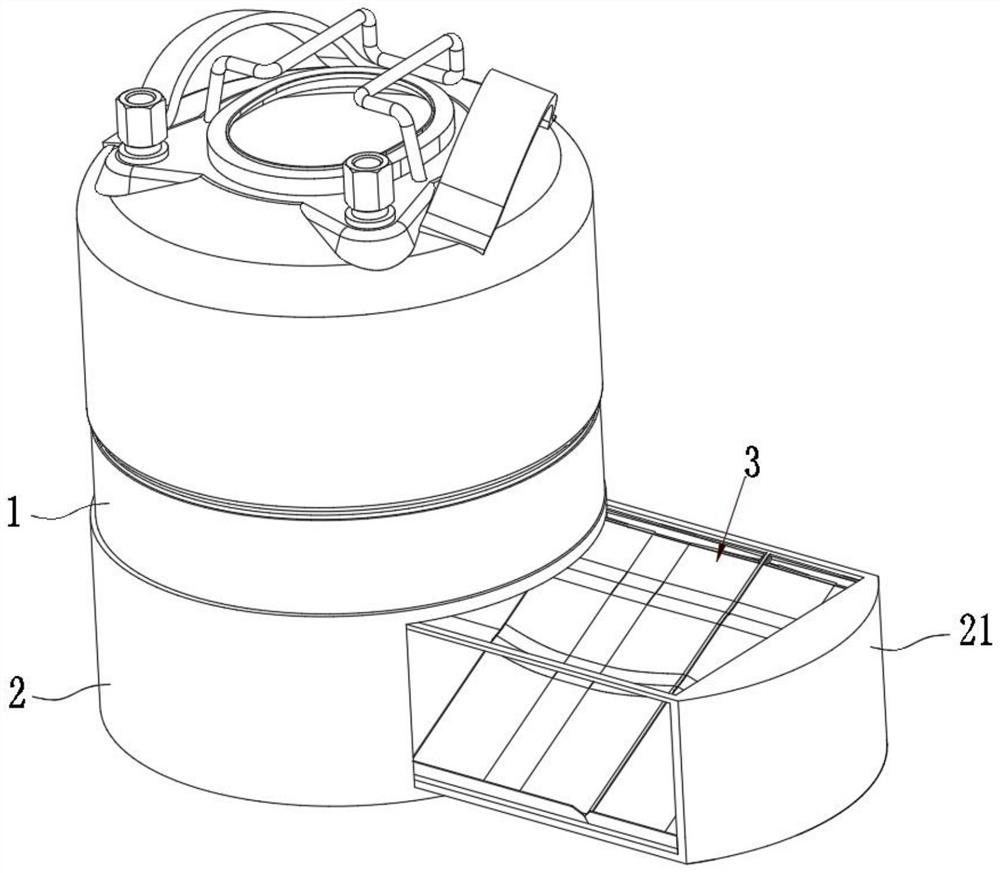

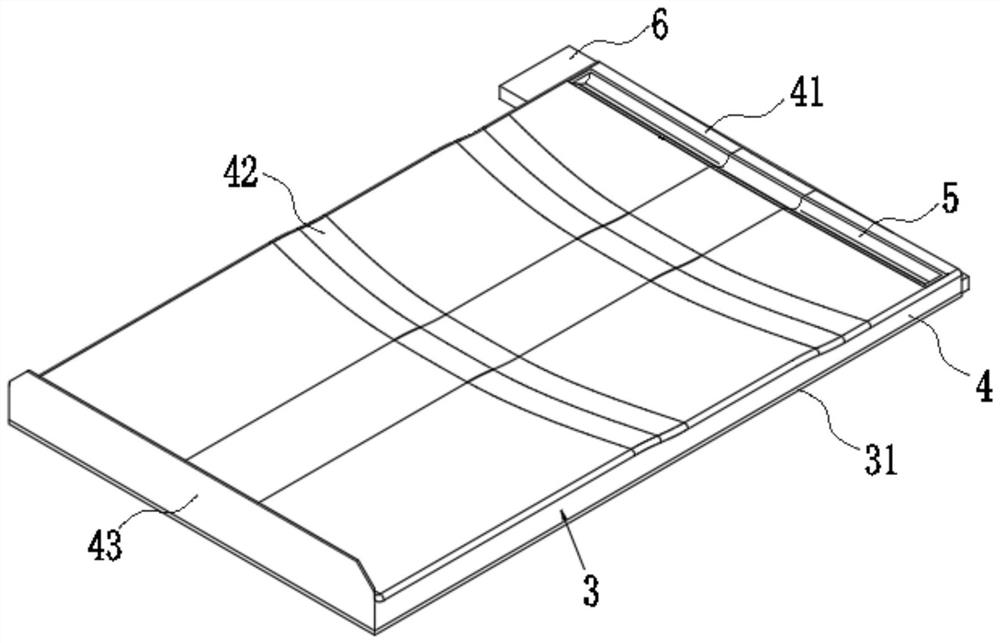

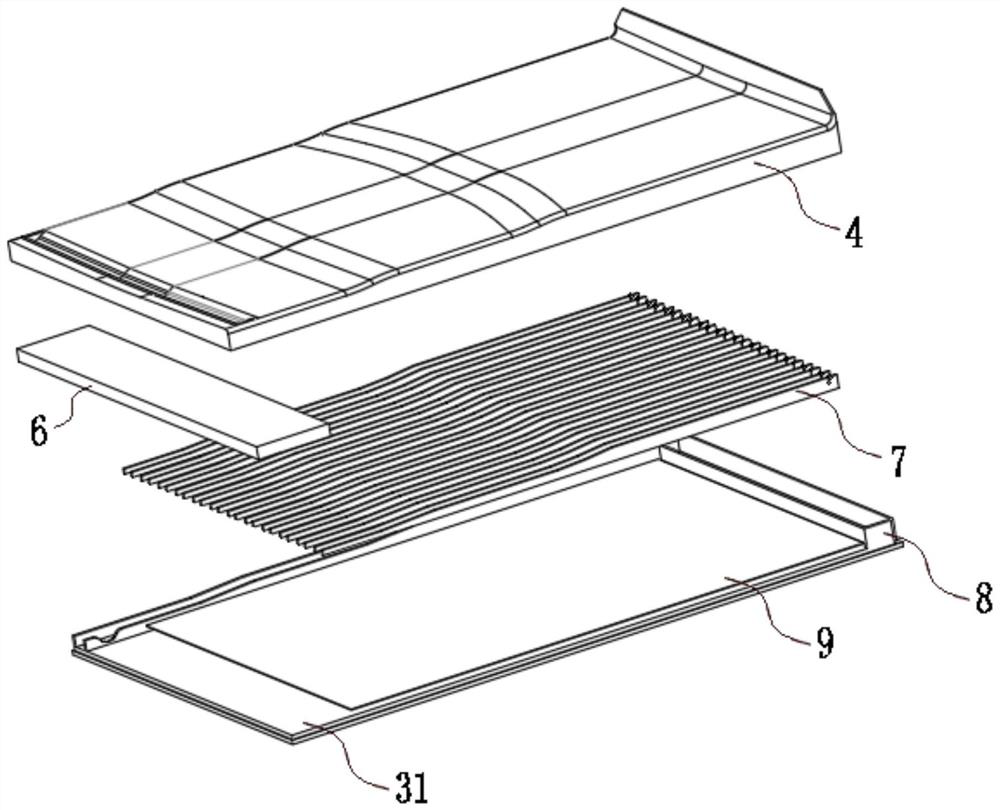

[0029] like figure 1 Shown in 7, a hyodeoxycholic acid extraction crystallizer comprises reaction tank 1 and the crystallization chamber 2 installed below the reaction tank 1, and a plurality of crystallization plates 3 are inclined in the crystallization chamber 2, and the reaction tank 1 discharges hot gas After being transferred to the crystallizing plate 3 after secondary heating, the reaction tank 1 discharges the liquid in the form of a water curtain, and the liquid flows along the inclined direction of the crystallizing plate 3 and is heated to evaporate and crystallize.

[0030] Specifically, in the above embodiment, the reaction tank 1 includes a tank body, a heating mechanism, a stirring mechanism, a feeding pipeline system and a quantitative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com