Uniform preparation device for physical foaming material

A technology of physical foaming and preparation device, which is applied in the field of uniform preparation devices for physical foam materials, can solve the problems of reducing the stirring efficiency and stirring uniformity of the device, affecting the service life of the device, reducing the production quality of products, etc., so as to increase the convenience , Improve the service life and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

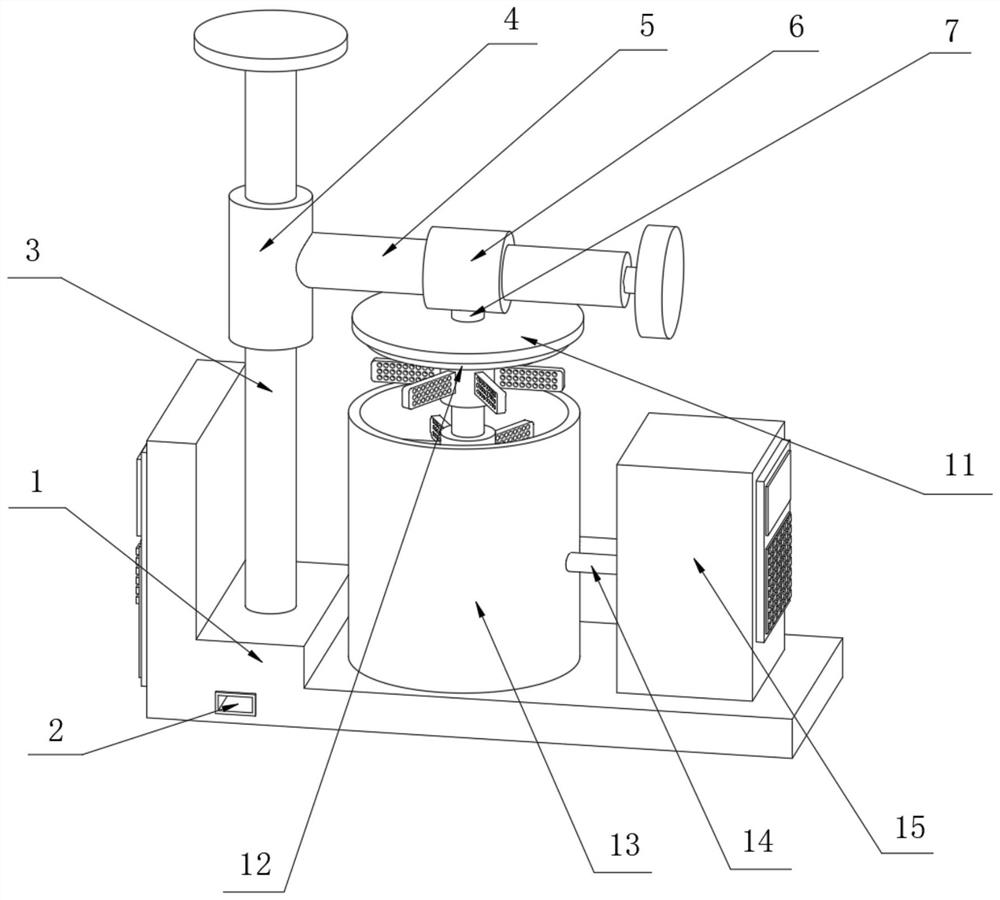

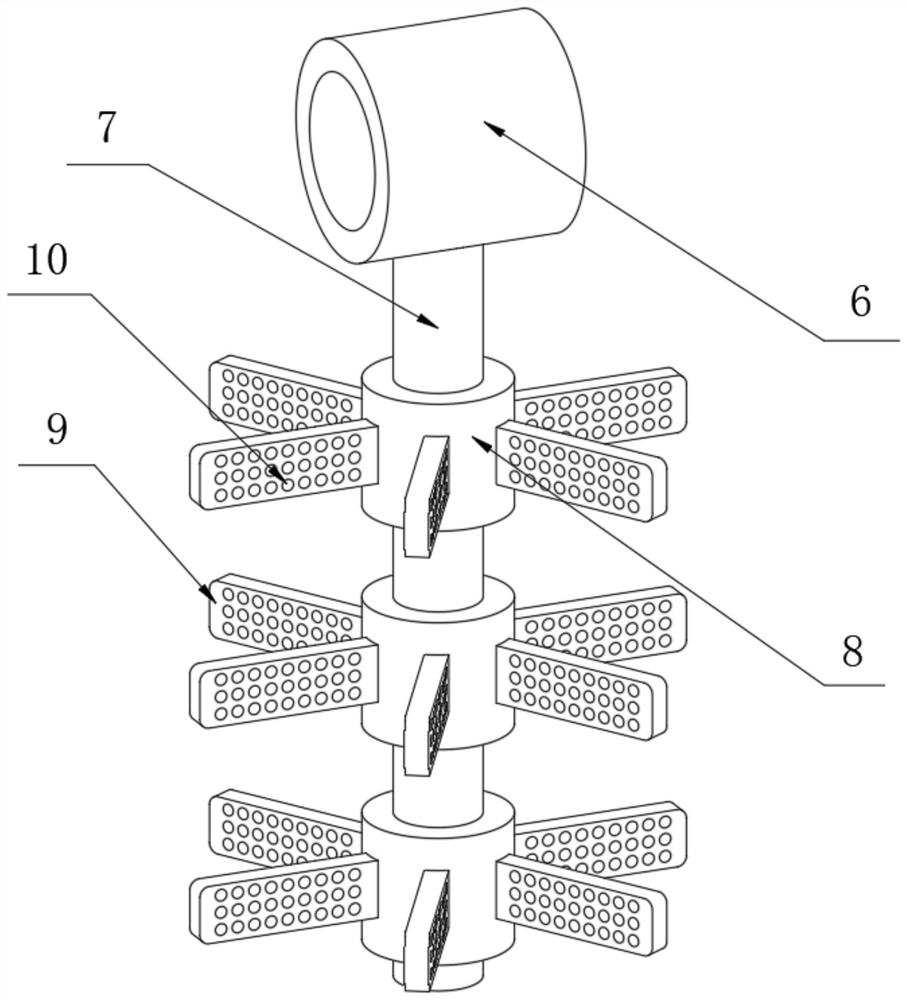

[0027] see Figure 1-6 , the present invention provides a technical solution: a uniform preparation device for physical foaming materials, comprising a power base 1, a power connection slot 2 is opened on the top of one side of the power base 1, and a support column 3 is fixedly installed on the top of the power base 1 , one side of the support column 3 is detachably installed with a sliding lifting regulator 4, the top of the sliding lifting regulator 4 side is fixedly connected with a transverse connecting rod 5, and one side of the transverse connecting rod 5 is detachably installed with a movable rod 6, which can move The bottom end of the rod 6 is fixedly connected with an installation connecting rod 7, one side of the installation connecting rod 7 is detachably installed with a power rotating shaft 8, one side of the power rotating shaft 8 is fixedly connected with a stirring blade 9, and the surface of the stirring blade 9 is provided with In the convection tank 10, the...

Embodiment 2

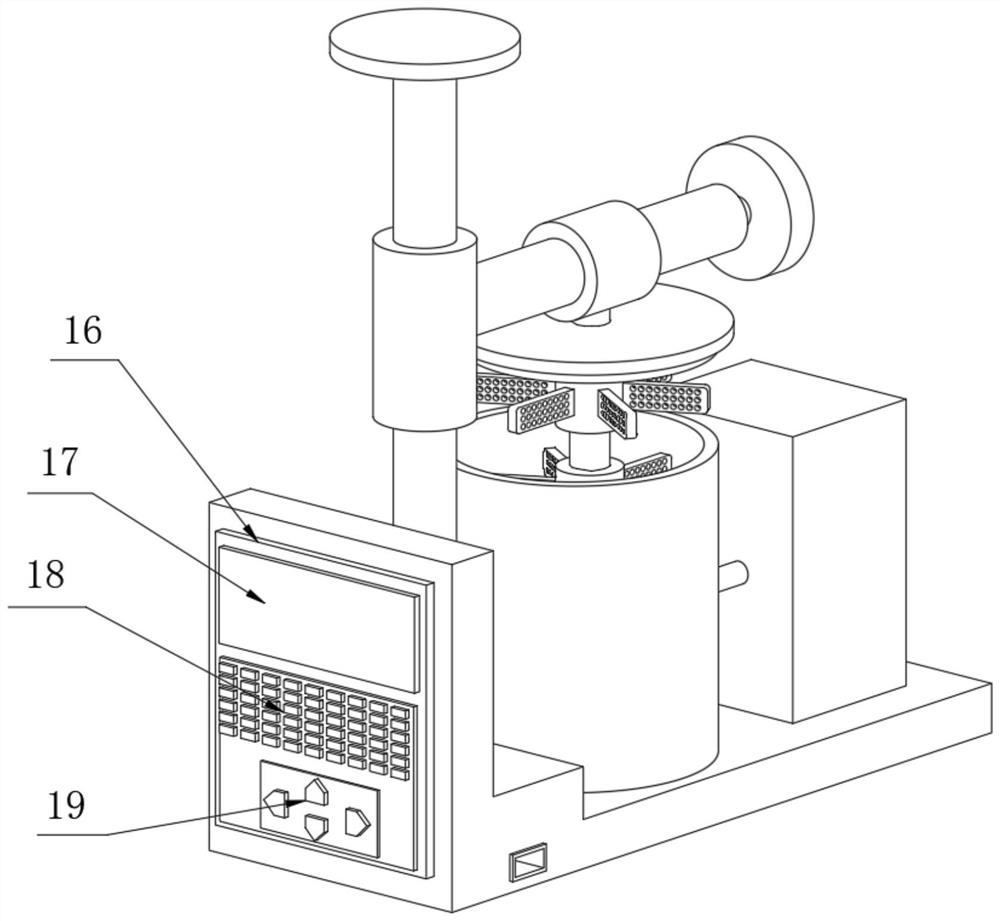

[0030] see Figure 1-6 As shown, on the basis of the first embodiment, the present invention provides a technical solution: a first main control panel 16 is fixedly installed on the top of one side of the power base 1 , and a display is fixedly installed on the front side of the first main control panel 16 17. A temperature setting disk 18 is detachably installed on one side of the display 17, a position adjusting disk 19 is detachably installed on one side of the temperature setting disk 18, and a first limit disk 20 is fixedly installed on the top of one side of the support column 3. A second limit plate 21 is fixedly installed on the top of one side of the connecting rod 5 , a second main control plate 22 is fixedly installed on the top of the gas controller 15 , and a gas is fixedly installed on the top of the front side of the second main control plate 22 A flow display screen 23, a gas flow setting plate 24 is detachably installed on one side of the gas flow display scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com