Automatic high-frequency quenching device for thin-wall short bushing

A high-frequency quenching and bushing technology, which is applied in the direction of quenching devices, energy efficiency, and process efficiency, can solve problems such as low production efficiency, high labor intensity, and health hazards for operators, so as to improve production efficiency and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

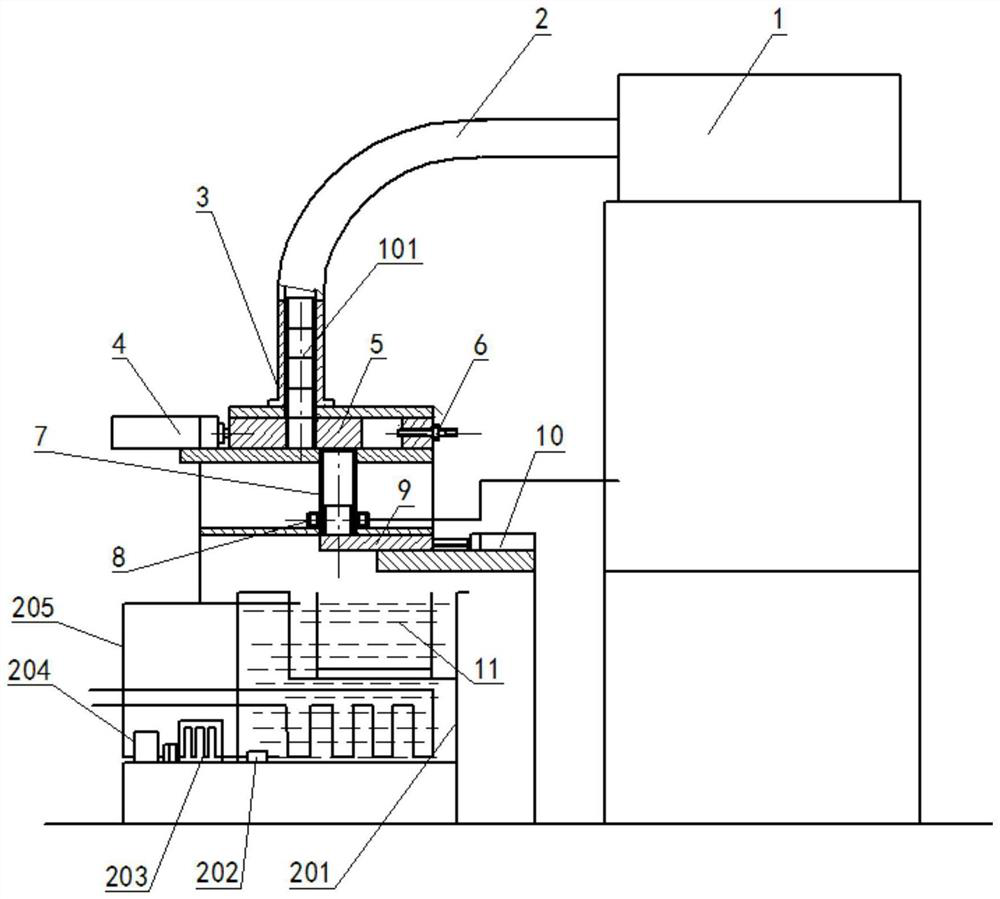

[0011] like figure 1 As shown in the figure, an automatic high-frequency diathermy and quenching cooling device for thin-walled short bushings includes a bed, a vibrating material distribution plate, a material pushing and closing mechanism, a high-frequency induction diathermy mechanism, a quenching liquid cooling mechanism and a PLC;

[0012] The vibrating material distribution plate 1 is composed of a material guide pipe 2 and an installation sleeve 3. One end of the material guide pipe 2 is installed at the material distribution port of the vibration material distribution plate 1, and the other end is connected with the installation sleeve 3 to the pusher in the material pusher mechanism. The feeding port opened above the material closure.

[0013] In the material pushing mechanism, a material pushing cylinder 4 is installed on the end face of the bed on the side of the material pushing mechanism. The middle position is provided with a circular hole slightly larger than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com