Composite integral heat-insulation assembled large wallboard and manufacturing method thereof

A technology of thermal insulation boards and wall panels, which is applied in the field of building wall panels, can solve the problems that the size of prefabricated wall panels is difficult to achieve the overall wall surface assembly, difficult to deal with construction gaps, and loss of prefabricated buildings, etc., to achieve enhanced waterproof and water-stop effects , The wall structure is stable and not easily deformed or damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

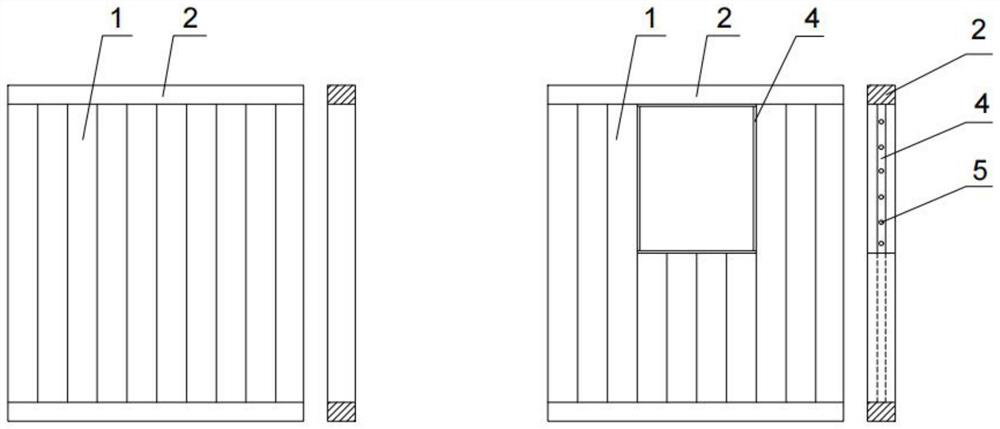

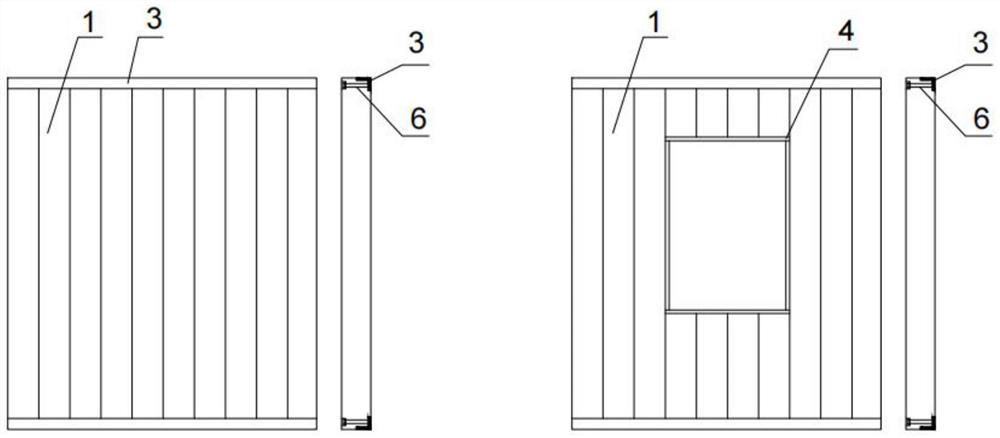

[0064] refer to Figure 1-6 A composite overall thermal insulation assembly large wall panel is shown, and the composite overall thermal insulation assembly large wall panel is a combined wall panel, which is assembled from a plurality of lightweight concrete strips 1; and a plurality of the lightweight concrete strips are assembled. The upper and lower ends of 1 are all poured with reinforced concrete connecting beams 2 or angle steel 3; the four peripheries of the door and window openings reserved on the composite overall thermal insulation assembly large wall panel are fixedly provided with flat steel 4;

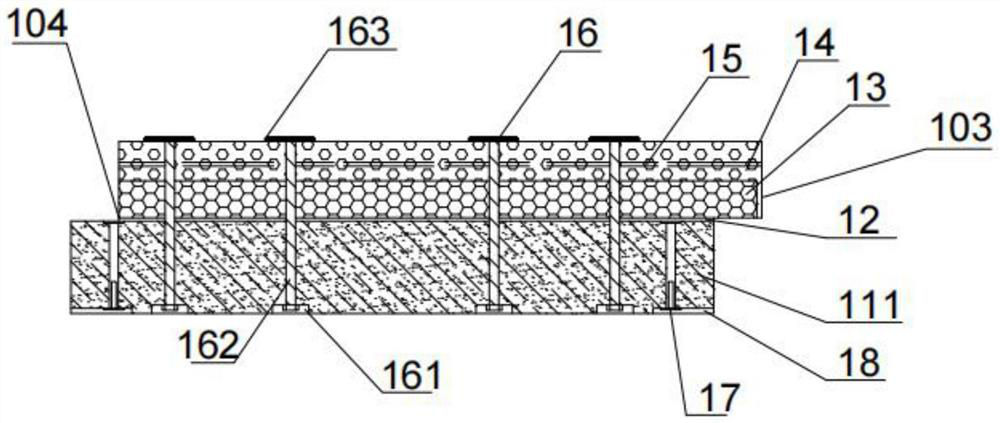

[0065] The lightweight concrete wall panel 1 includes a base board 11 , an adhesive layer 12 , a thermal insulation board 13 and a protective layer 14 ; the upper side of the base board 11 is bonded to the lower side of the thermal insulation board 13 through the adhesive layer 12 . ; The upper side and the side surface of the insulation board 13 are cast with the protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com