Diaphragm compression type linear compressor system for high-frequency pulse tube refrigerator

A linear compressor and high-frequency pulse technology, which is applied in refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problems of high cost and high processing/assembly precision requirements, and achieve cost reduction, high-precision processing and assembly Requirement, development and positive promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

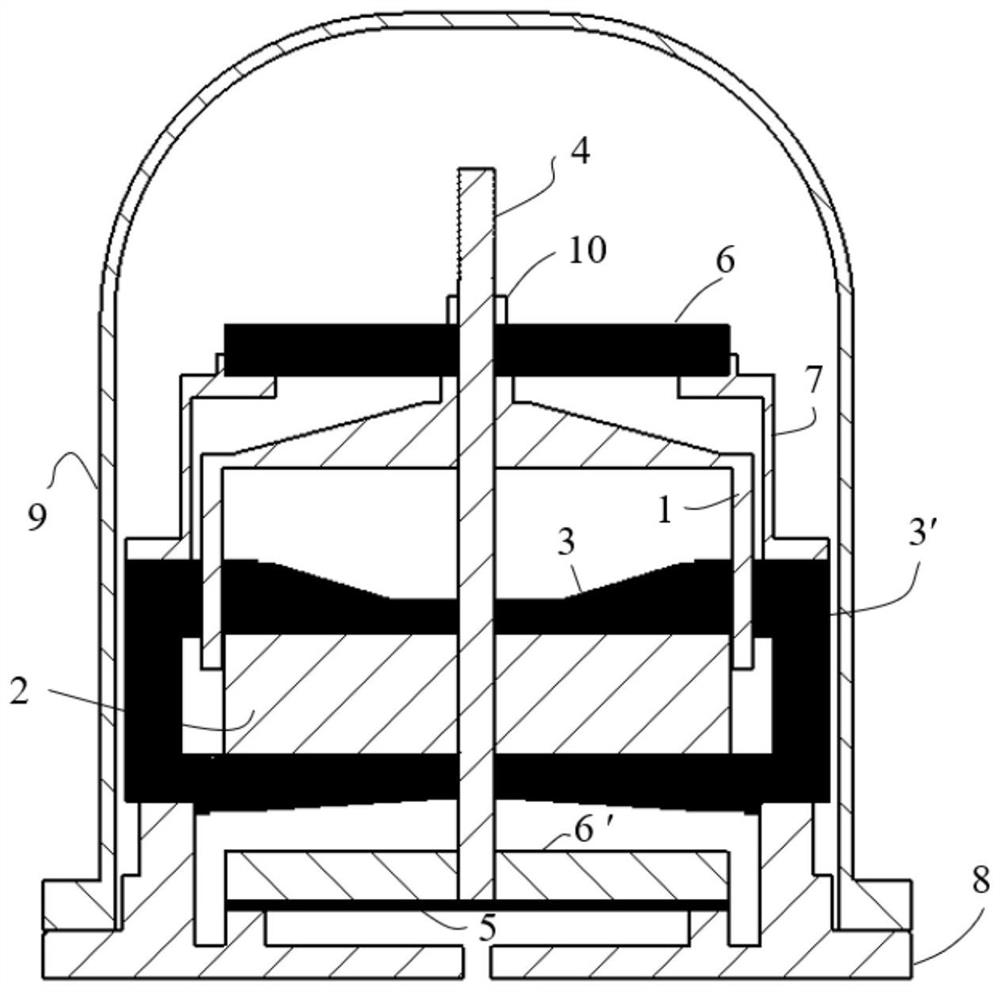

[0030] A diaphragm compression linear compressor system for a high-frequency pulse tube refrigerator, such as figure 1 As shown, it includes coil 1, permanent magnet 2, upper yoke 3, lower yoke 3', push rod 4, diaphragm 5, upper leaf spring 6, lower leaf spring 6', leaf spring support frame 7, cylinder 8, housing 9 and lock nut 10;

[0031] The push rod 4 and the diaphragm 5, the lower leaf spring 6', the coil 1, the upper leaf spring 6 and the lock nut 10 pass through the push rod 4 in turn through the central positioning hole, and pass through the thread at the tail of the push rod 4 and the lock nut 10 The screw is mechanically fixed to form a mover component; the diaphragm 5 and the lower leaf spring 6' are fixed to the lower boss (ie the low boss) of the cylinder 8 through a set of screws, and the lower yoke 3' is fixed to the cylinder through a set of screws. 8. The upper boss (that is, the high boss, the high boss and the low boss are coaxial and the high boss is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com