Lithium ion battery formation method

A lithium-ion battery and formation method technology, which is applied in the field of lithium-ion battery formation, can solve the problems of wasting cost and process time, time and many operators, complicated process, etc., and achieve consistent thickness, improved cycle performance, and consistent capacity performance, good interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

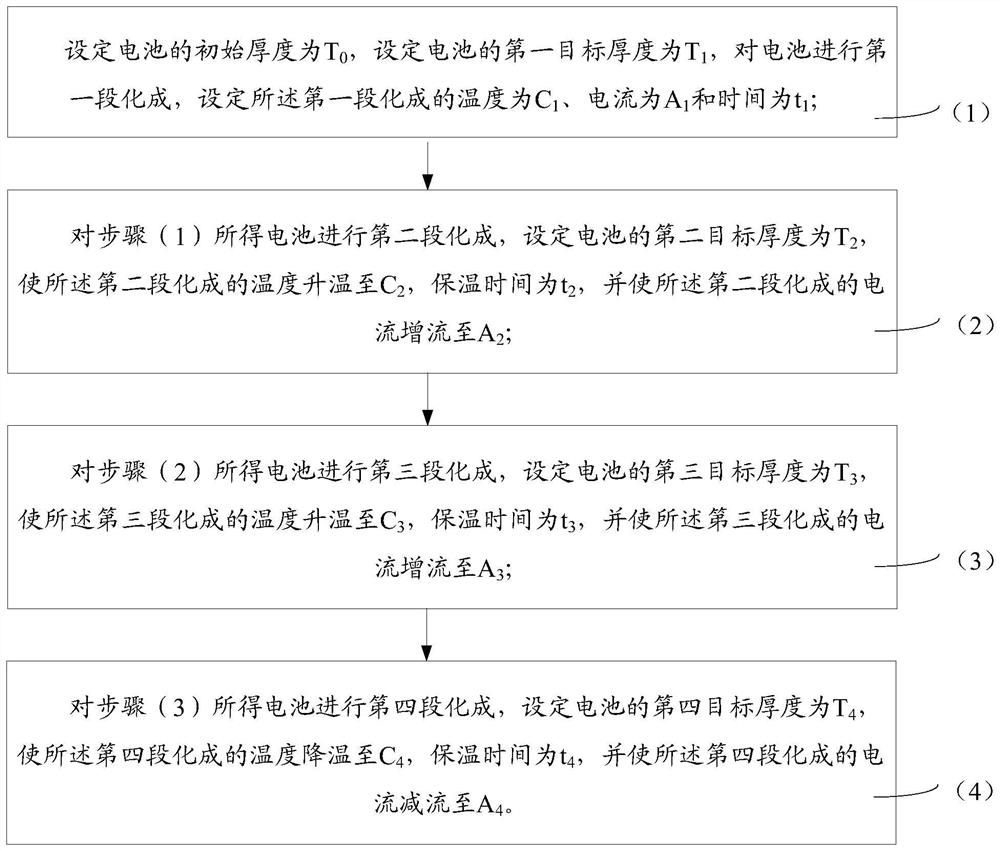

[0029] The lithium-ion battery formation method includes the following steps:

[0030] (1) Set the initial thickness of the battery as T 0 , set the first target thickness of the battery as T 1 , carry out the first-stage formation of the battery, and set the temperature of the first-stage formation as C 1 , the current is A 1 and time t 1 ;

[0031] (2) The second-stage formation is performed on the battery obtained in step (1), and the second target thickness of the battery is set as T 2 , the temperature of the second section is heated to C 2 , the holding time is t 2 , and increase the current formed by the second section to A 2 ;

[0032] (3) The third stage of formation is performed on the battery obtained in step (2), and the third target thickness of the battery is set as T 3 , so that the temperature of the third-stage formation is raised to C 3 , the holding time is t 3 , and increase the current formed by the third stage to A 3 ;

[0033] (4) The fourth...

Embodiment 2

[0039] The lithium-ion battery formation method includes the following steps:

[0040] (1) Set the initial thickness of the battery as T 0 , set the first target thickness of the battery as T 1 , carry out the first-stage formation of the battery, and set the temperature of the first-stage formation as C 1 , the current is A 1 and time t 1 ;

[0041] (2) The second-stage formation is performed on the battery obtained in step (1), and the second target thickness of the battery is set as T 2 , the temperature of the second section is heated to C 2 , the holding time is t 2 , and increase the current formed by the second section to A 2 ;

[0042] (3) The third stage of formation is performed on the battery obtained in step (2), and the third target thickness of the battery is set as T 3 , so that the temperature of the third-stage formation is raised to C 3 , the holding time is t 3 , and increase the current formed by the third stage to A 3 ;

[0043] (4) The fourth...

Embodiment 3

[0049] The lithium-ion battery formation method includes the following steps:

[0050] (1) Set the initial thickness of the battery as T 0 , set the first target thickness of the battery as T 1 , carry out the first-stage formation of the battery, and set the temperature of the first-stage formation as C 1 , the current is A 1 and time t 1 ;

[0051] (2) The second-stage formation is performed on the battery obtained in step (1), and the second target thickness of the battery is set as T 2 , the temperature of the second section is heated to C2 , the holding time is t 2 , and increase the current formed by the second section to A 2 ;

[0052] (3) The third stage of formation is performed on the battery obtained in step (2), and the third target thickness of the battery is set as T 3 , so that the temperature of the third-stage formation is raised to C 3 , the holding time is t 3 , and increase the current formed by the third stage to A 3 ;

[0053] (4) The fourth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com