Welding device for extremely simple cover plate

A welding device and cover plate technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve problems such as burns to workers and damage to workers' personal health, and achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

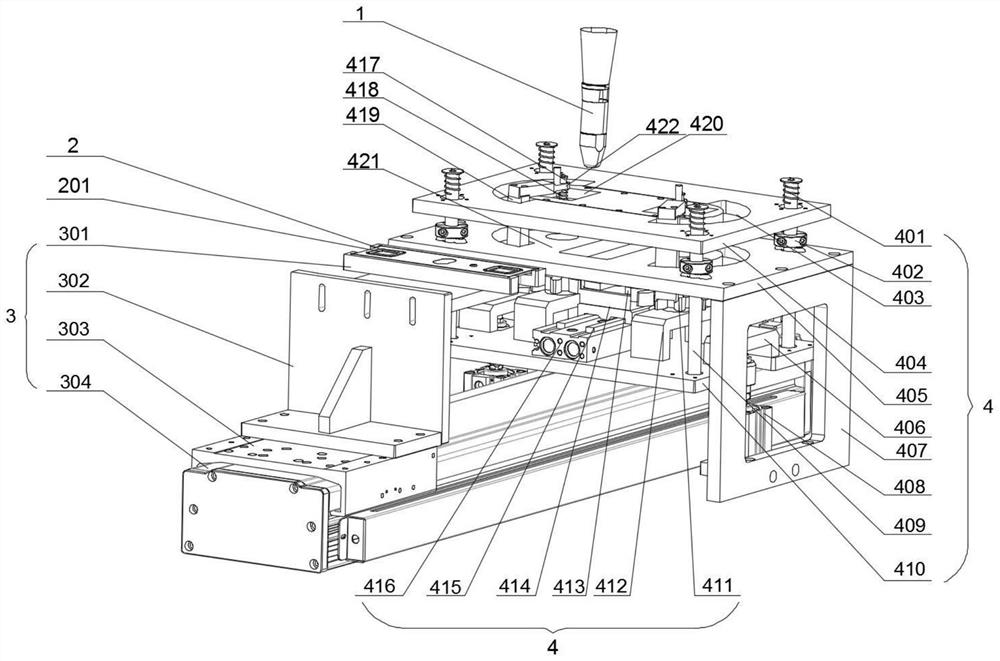

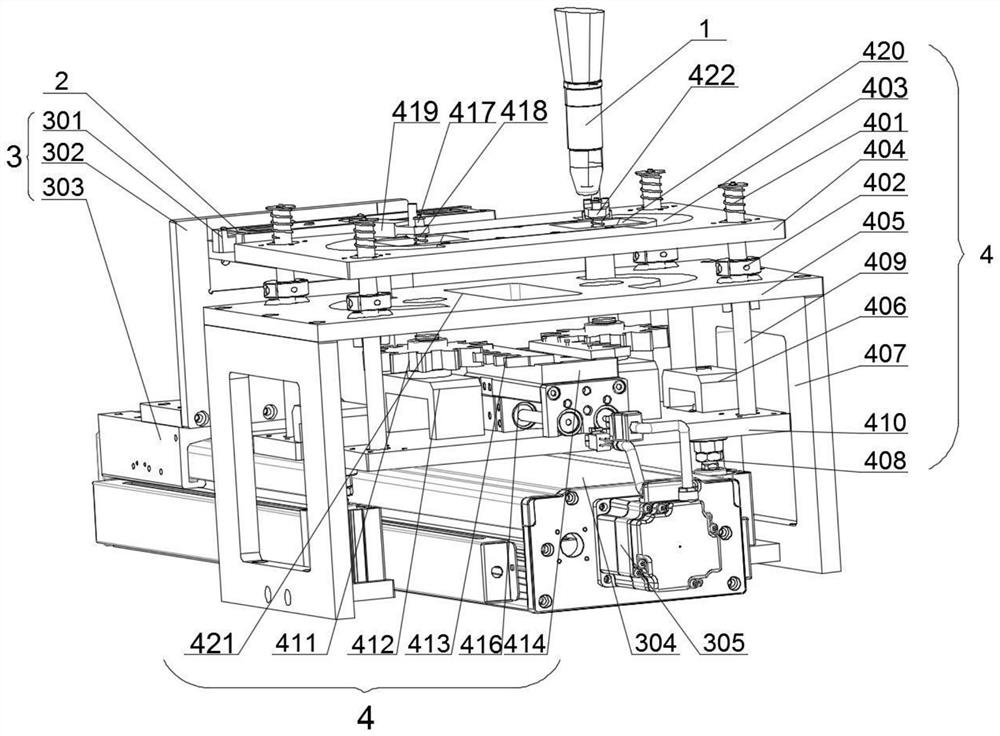

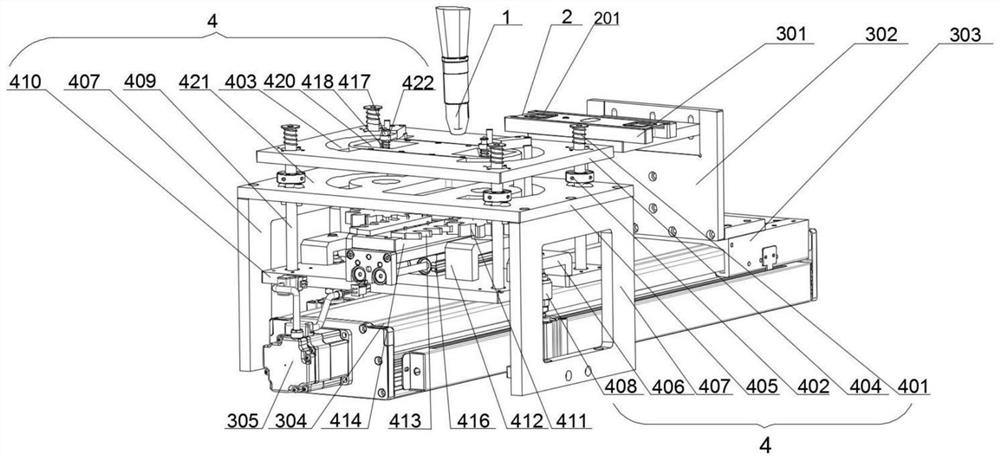

[0025] like figure 1 and figure 2 As shown, a welding device for a minimalist cover plate of the present invention includes a working platform placed on the ground, a welding mechanism 1 , a feeding mechanism 3 and a clamp 4 arranged on the working platform.

[0026] like figure 1 and figure 2 As shown, the feeding mechanism 3 is used to position the minimalist cover plate 2 installed with the positive and negative poles 201 and transfer it into the fixture 4 so that the welding mechanism 1 welds the positive and negative poles 201 to the minimalist cover plate 2. On the top, the feeding mechanism 3 includes a slide rail 304 fixed on the working platform and distributed along the width direction of the working platform. The slide rail 304 is provided with a lead screw distributed along the length direction of the slide rail 304, and a slider is installed on the lead screw in a sliding fit. 303. The shape of the slider 303 is a zigzag shape, and the slider 303 is connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap