Aluminum veneer machining surface grinding equipment facilitating feeding

An aluminum veneer and equipment technology, applied in the field of surface grinding equipment for aluminum veneer processing, can solve the problems of easily punctured workers, burrs, and low efficiency of grinding operations, so as to expand the scope of grinding, improve grinding efficiency, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

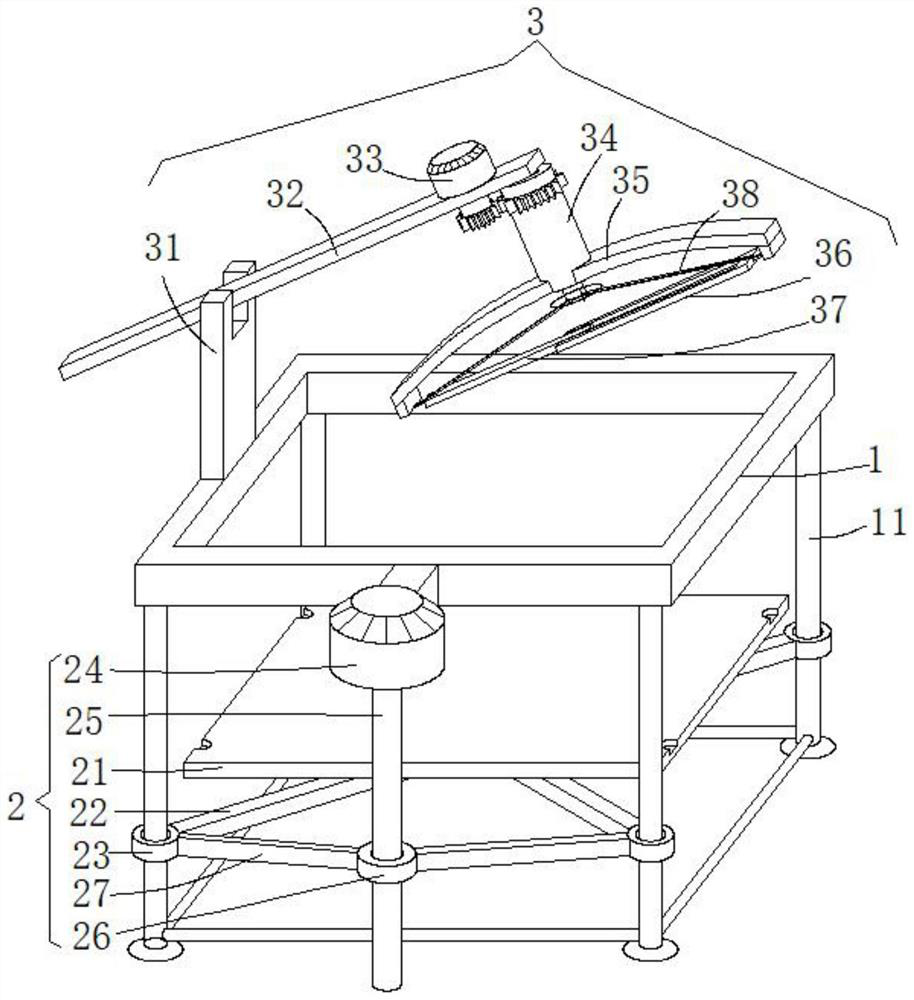

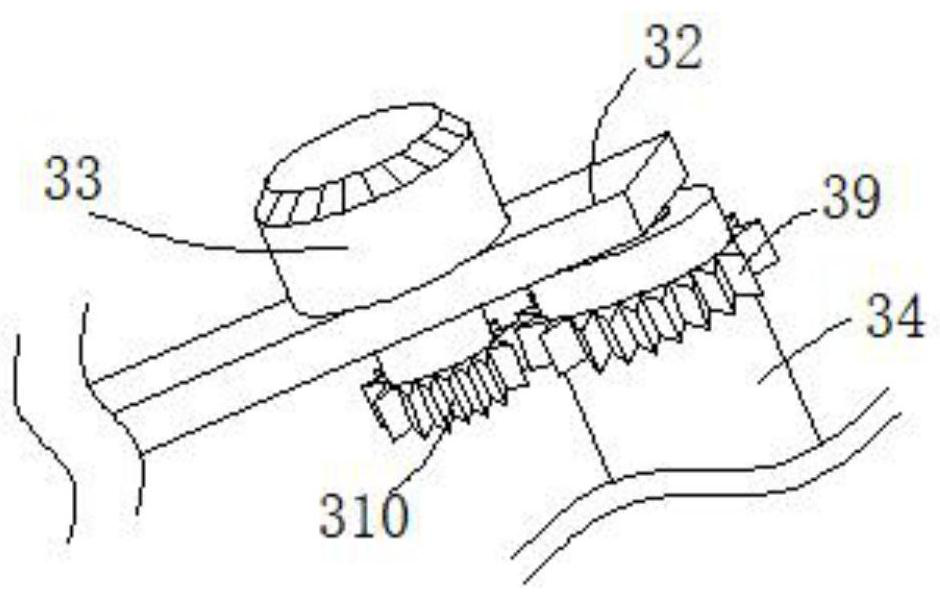

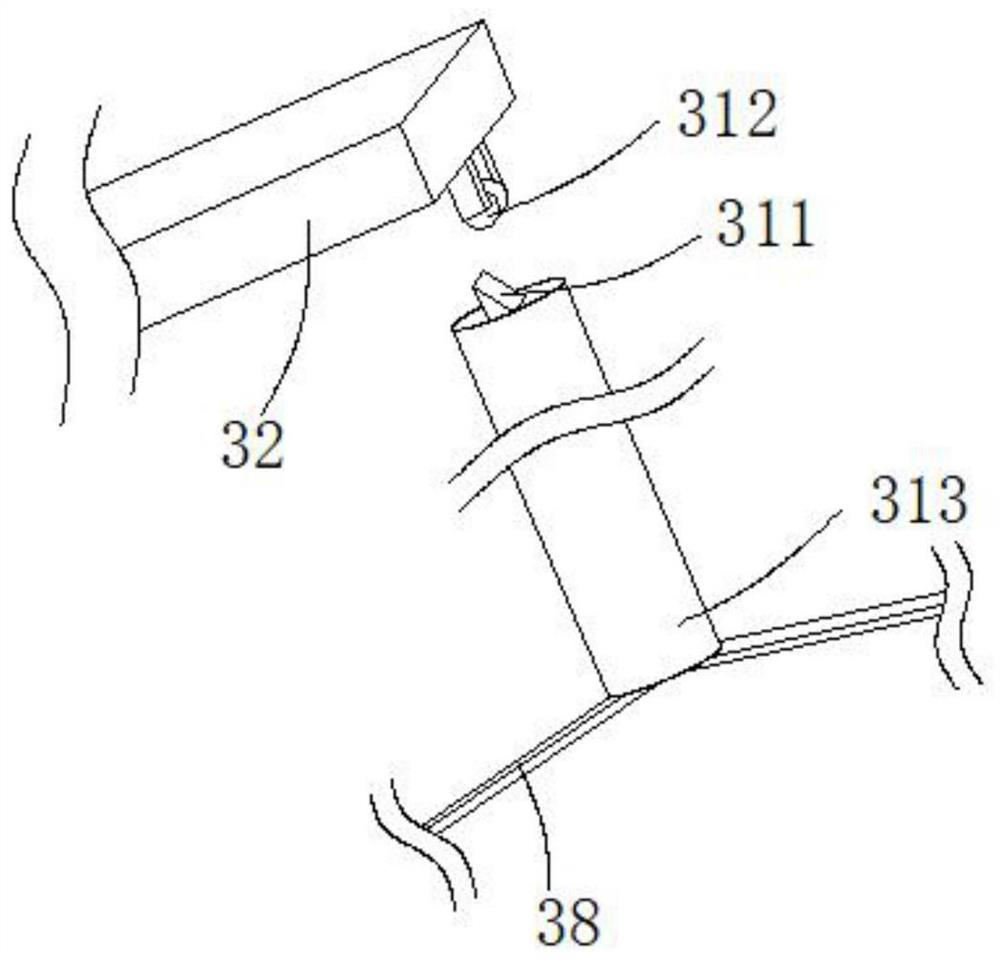

[0034] see Figure 1-4 and Image 6 , this embodiment provides a surface grinding equipment for aluminum veneer processing that is easy to load, including a support frame 1, a support mechanism 2 and a grinding mechanism 3, and the bottom end corners of the support frame 1 are vertically fixed with support legs. 11. The support legs 11 can vacate the support frame 1 and use it as a support frame for grinding.

[0035] The support mechanism 2 includes a servo motor 24, a support base plate 21, an X-shaped bracket 22 and four sliding sleeves 23. The central position of the X-shaped bracket 22 is vertically fixed with a vertical column 28, and the support base plate 21 is located between the four support legs 11. The four sliding sleeves 23 are respectively fixed on the four corner positions of the X-shaped bracket 22. The sliding sleeves 23 are slidably sleeved with the outer wall of the support leg 11, and the X-shaped bracket 22 passes through the column. 28 The support base...

Embodiment 2

[0049] see figure 1 , Figure 5 and Figure 7 , made further improvements on the basis of Example 1:

[0050] During the grinding process of the second grinding block 37 and the first grinding block 36, only one side of the aluminum veneer can be ground, and the aluminum veneer needs to be manually lifted to turn the aluminum veneer, which affects the grinding efficiency of the aluminum veneer. Affecting the production efficiency of the finished aluminum veneer, a flipping mechanism 4 is provided inside the support frame 1, and the flipping mechanism 4 is used to flip the aluminum veneer that has been polished on one side, so as to facilitate the grinding operation for the other one and improve the performance of the aluminum veneer. Grinding efficiency.

[0051] The overturning mechanism 4 includes two longitudinal support rods 41 and two butt transverse plates 42. The two butt transverse plates 42 are distributed in front and back facing each other, and are rotatably conn...

Embodiment 3

[0054] see figure 1 , Figure 5 , Figure 7 , Figure 8 and Figure 9 , made further improvements on the basis of Example 2:

[0055] In order to enhance the stability of the overturning mechanism 4 overturning the aluminum veneer and avoid the phenomenon that the aluminum veneer falls from between the two longitudinal support rods 41 , an adjustment cavity is provided inside the longitudinal support rod 41 , and the inside of the adjustment cavity is provided with a limiter. The positioning mechanism 5 is used to limit the position of the aluminum veneer during the overturning process, so as to ensure the effective overturning operation, and finally improve the grinding efficiency of the aluminum veneer.

[0056] The limit mechanism 5 includes a top rod 51, a hinge rod 53 and several limit blocks 52. The upper and lower side walls of the longitudinal support rod 41 are provided with rectangular adjustment holes 46 that communicate with the inside of the adjustment cavity. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com