Rapid cooling method for precision heat treatment steel belt

A heat treatment steel and rapid cooling technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low cooling efficiency and effect, reduced heat conduction efficiency, and fast cooling liquid temperature rise, achieving strong functionality and improving work efficiency , good automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

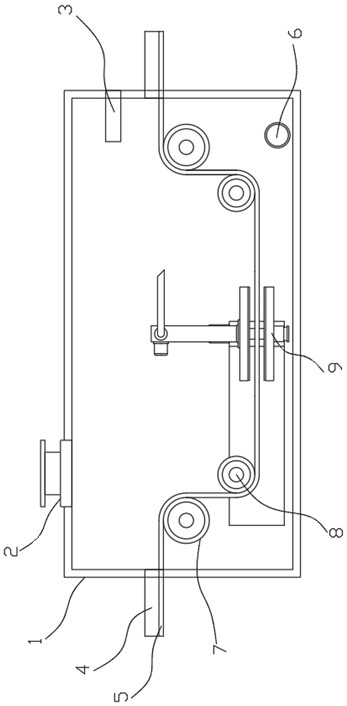

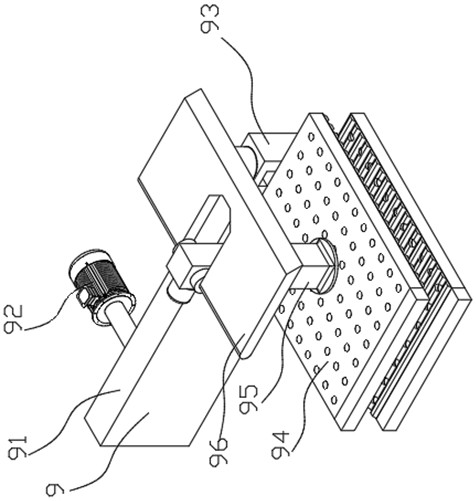

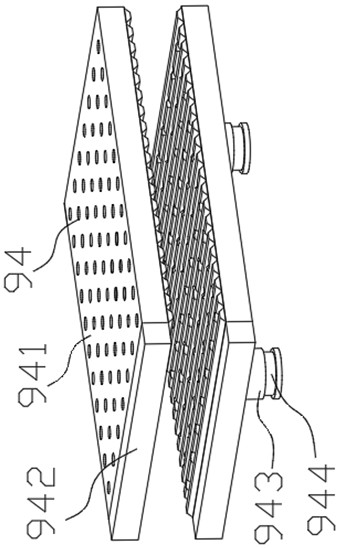

[0038] see figure 1 , the present invention provides a rapid cooling method for precision heat-treated steel strips, comprising a cooling bin 1, an injection pipe 2 is installed at the top left end of the cooling bin 1, a lead-out part 3 is fixed at the upper right end of the cooling bin 1, and the left and right ends of the cooling bin 1 are A connecting pipe 4 is fixed, the two sets of connecting pipes 4 are penetrated by the steel belt 5, and the steel belt 5 enters the cooling bin 1. The left and right ends of the cooling bin 1 are provided with upper guide rollers 7, and lower guide rollers are installed below the upper guide roller 7. 8. The steel belt 5 moves along the outer sides of the upper guide roller 7 and the lower guide roller 8. A drain pipe 6 is provided at the lower right end of the cooling chamber 1, and an auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com