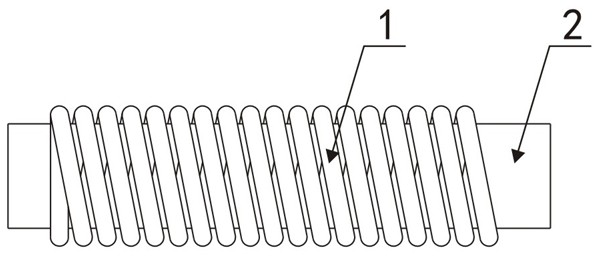

Manufacturing method and forming tool of high-precision resistor body for multi-circle angular displacement potentiometer

A technology of forming tooling and manufacturing methods, which is applied in the direction of winding resistance elements, manufacturing packaged/housing resistors, etc., can solve the problems of reduced service life of brushes, low service life of resistors, and difficulty in raising the service life to a higher level. , to achieve the effect of improving service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings:

[0028] The method for making a high-precision resistor body for a multi-turn angular displacement potentiometer according to the present invention includes the following steps:

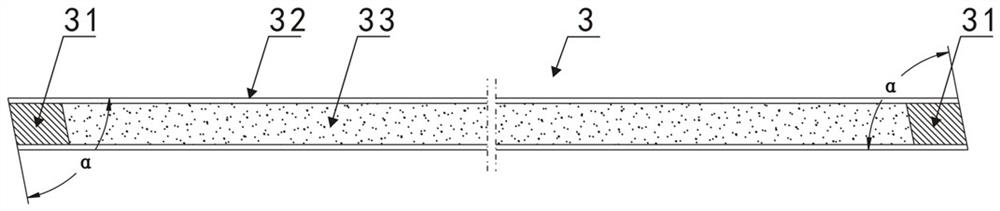

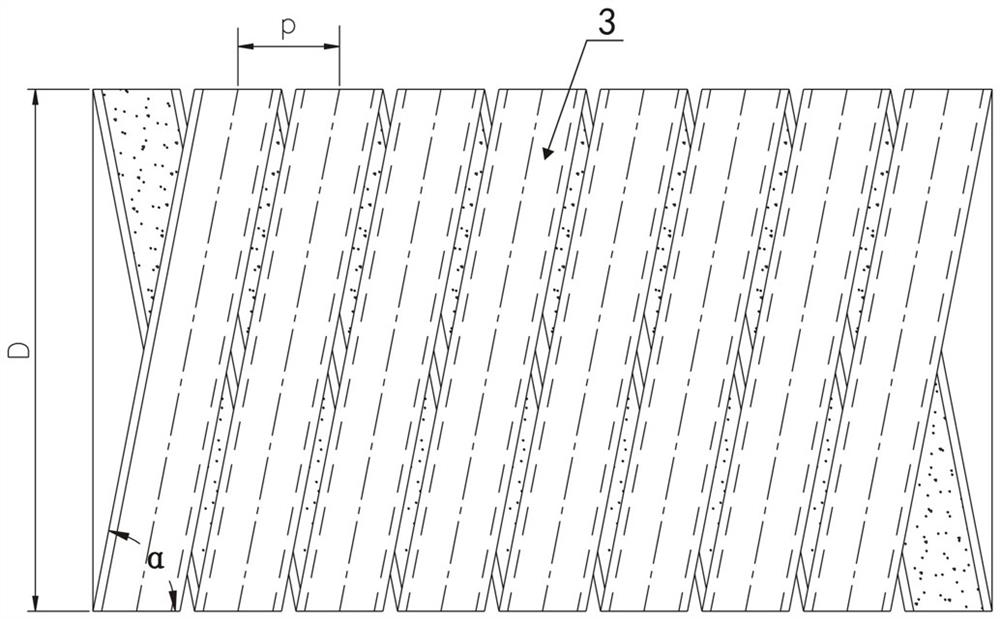

[0029] Step 1. Make the resistance band 3: as figure 2 As shown, the conductive plastic in paste state is arranged on the surface of the long strip-shaped polyimide film 32 by printing or molding, and electrodes are respectively printed on the polyimide film 32 at the positions outside the two ends of the conductive plastic. 31. The electrode 31 is a silver paste electrode. The electrode 31 and the conductive plastic are connected to each other. After the conductive plastic is solidified, a conductive plastic resistance film 33 is formed. After the conductive plastic and the electrode 31 are solidified, the resistance band 3 is formed together with the polyimide film 32. , wherein, the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com