Velvet carpet with high and low velvet feelings

A high-low pile and carpet technology, applied in the field of velveteen carpets, can solve problems such as difficult cleaning, and achieve the effects of easy care, convenient transportation, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

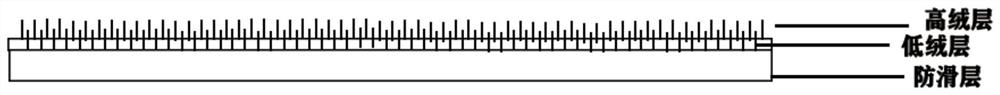

[0095] The present embodiment relates to a kind of carpet; the preparation of this carpet comprises the following steps, is made up of the following structural layers:

[0096] Carpet surface layer: including high and low pile layers.

[0097] Bottom layer: made of thermoplastic elastomer layer.

[0098] 1) Yarn selection: Select polyester 4.5-count chenille yarn and polyester 5.5-count feather yarn, the ratio is 30% feather yarn: 70% chenille yarn.

[0099] 2) Make a blanket surface layer: Weaving the yarn in step 1 with a double-sided jacquard circular knitting machine, weaving arrangement: the upper needle is in the way of "123123123123", and the lower needle is in the way of "123412341234"; the weaving process is 12 passes One cycle, the threading method of chenille yarn and feather yarn is one stitch and one stitch.

[0100] 3) Forming the suede layer: The fabric in step 2 is subjected to the water drop process using the overflow tank, and the fabric is continuously rot...

Embodiment 2

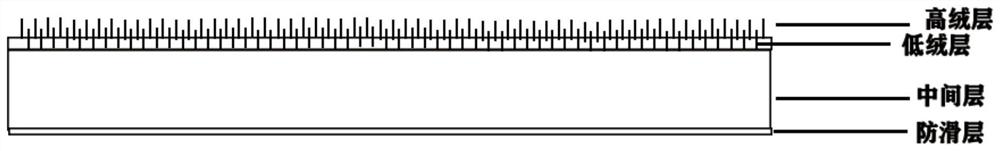

[0105] The present embodiment relates to a kind of carpet; the preparation of this carpet comprises the following steps, is made up of the following structural layers:

[0106] Carpet surface layer: including high and low pile layers.

[0107] Middle layer: non-woven layer.

[0108] Bottom layer: made of thermoplastic elastomer layer.

[0109] 1) Selection of yarn: choose polyester 3 ice strip yarns and 4 pile yarns, the ratio is 50% pile yarn: 50% ice strip.

[0110] 2) Making the carpet surface layer: Weaving the yarn in step 1 with a rapier loom, threading the yarn into the steel buckle according to the method of one buckle and one insertion.

[0111]3) Forming the suede layer: the fabric in step 2 is subjected to wet heat treatment with a ball rolling machine, and the fabric is continuously rubbed in the machine, so that after the yarn is rubbed against the box, the fluff is made to stand upright, forming an upright feeling similar to tufted fabric . The temperature wa...

Embodiment 3

[0117] The present embodiment relates to a kind of carpet, and the preparation of the imitation tufted plain weave carpet comprises the following steps, and is composed of the following structural layers:

[0118] Carpet surface layer: including high and low pile layers.

[0119] Middle layer: non-woven layer.

[0120] Bottom layer: made of thermoplastic elastomer layer.

[0121] 1) Selection of yarn: Select polyester 3.5-count chenille yarn to dye it blue and white using a tie-dyeing process, and select polyester 4.5-count seahorse yarn. The ratio is 30% seahorse yarn: 70% chenille yarn.

[0122] 2) Made of carpet surface layer: the finished yarn is woven with double-sided jacquard circular knitting machine, weaving arrangement: the upper needle is in the way of "123123123123", and the lower needle is in the way of "123412341234"; the weaving process is 15 loops per cycle , The needle threading method of chenille yarn and hippocampus yarn is one stitch and one stitch.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com