Extraction and refinement equipment for raw material of rose cell sap for skin care

A cell fluid and raw material technology, which is applied in the field of extraction and refining equipment for rose cell fluid raw materials for skin care, can solve the problems of uneven contact, affect the taste quality of cell fluid, and excessive drying of roses, and achieve the effect of accelerating extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

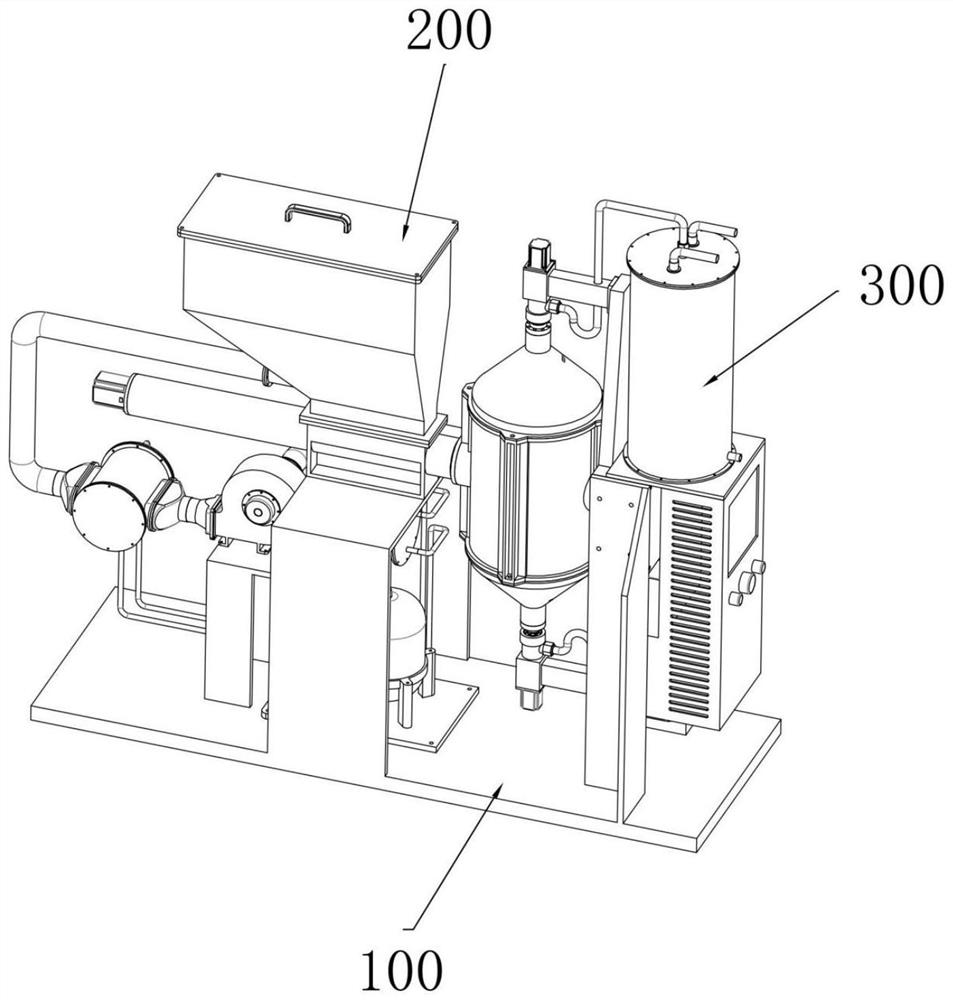

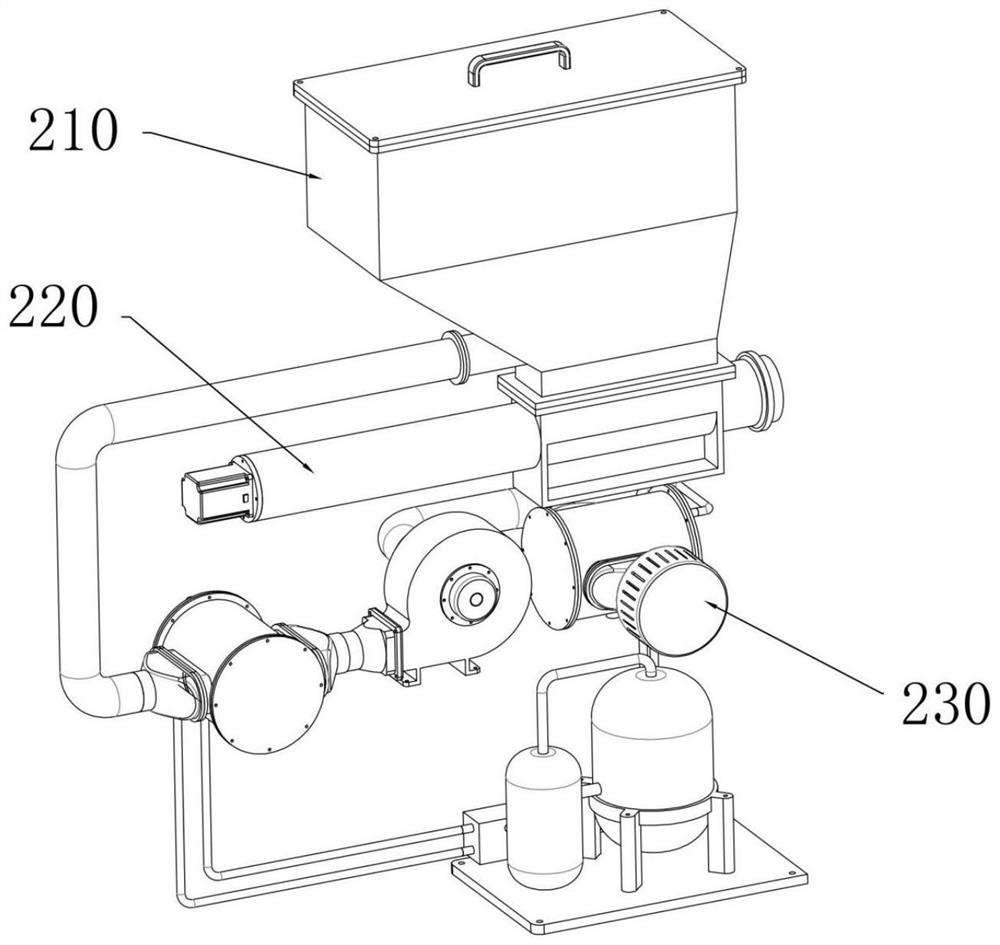

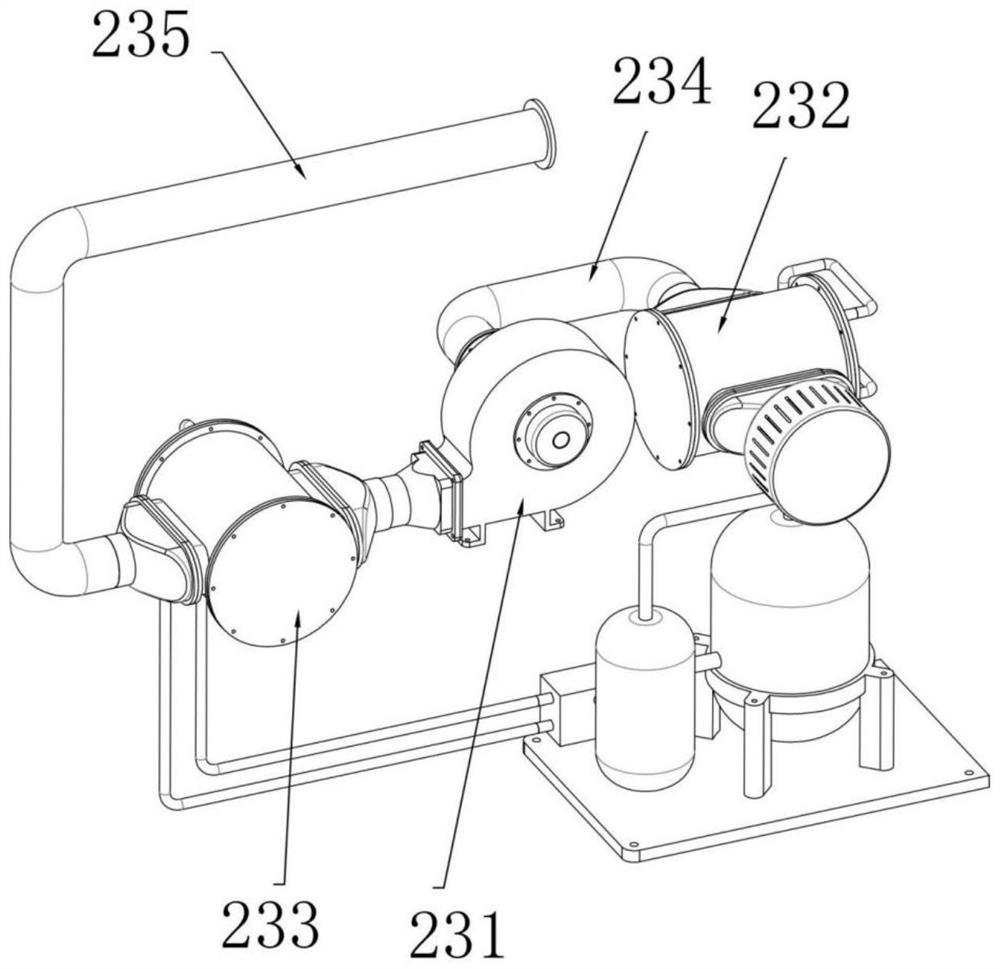

[0068] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0069] Rose cytosol is the liquid evaporated from rose petals or rose buds during low-temperature drying. The preparation of existing rose cytosol is generally by directly placing the picked roses into the drying room, and drying them through the drying process. The hot air dries the rose, and at the same time, the hot air takes away the cell sap in the rose, and then condenses it to obtain the rose cell sap, which has the following problems:

[0070] 1. Roses are generally put directly into the drying room of the rose corolla or rose buds, without pre-processing, the petals of the roses are not separated, resulting in a low efficiency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com