Preparation method of copper-based powder metallurgy friction material

A technology of mixing materials and manufacturing devices, which is applied in the field of material processing, and can solve problems affecting the mechanical properties of finished materials and uneven distribution of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] use Figure 1-Figure 8 A method for preparing a copper-based powder metallurgy friction material according to an embodiment of the present invention is described as follows.

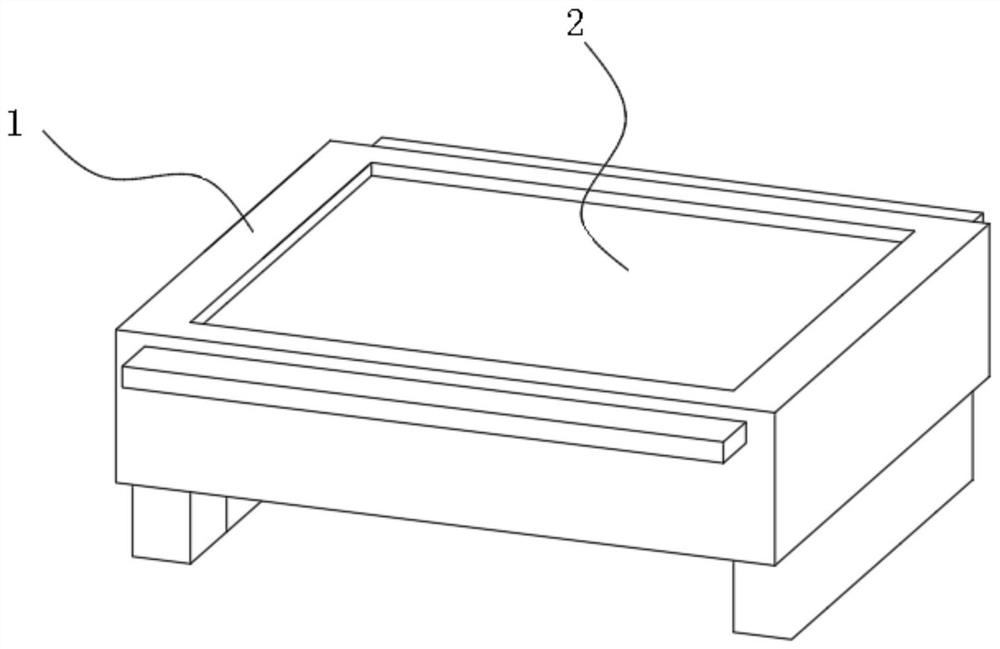

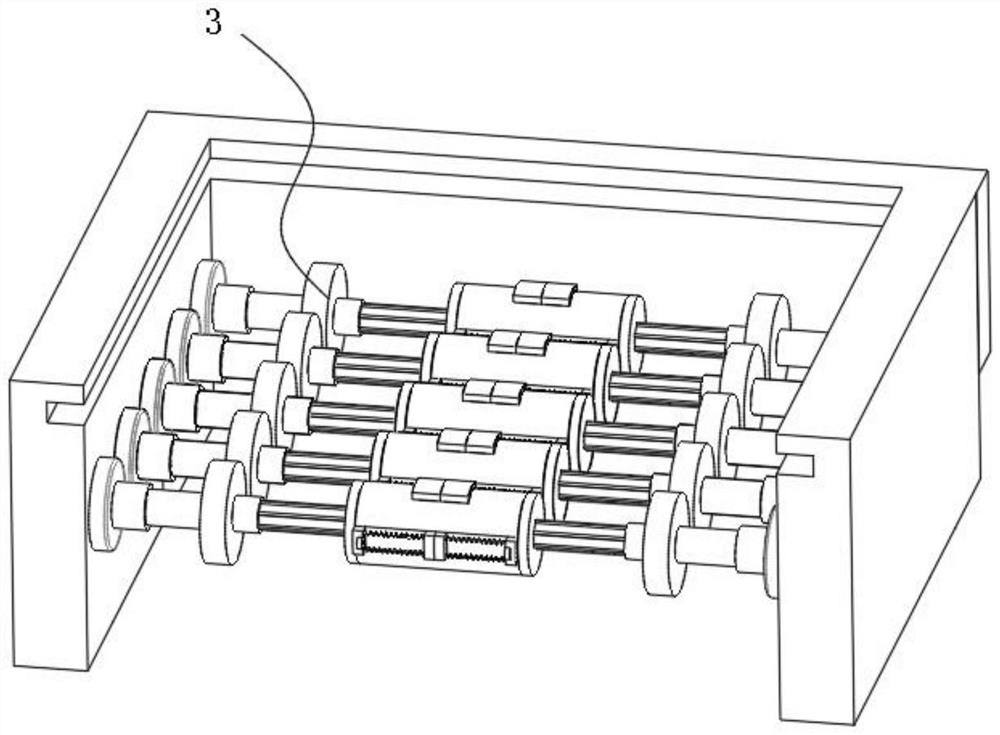

[0034] like Figure 1-Figure 8 As shown in the figure, a mixed material manufacturing device according to the present invention includes a main box frame 1, the upper part of the inner cavity of the main box frame 1 is provided with a through slot, and the upper part of the inner wall of the main box frame 1 is slidably connected with a partition through the through slot. In the thermal protection plate 2, the left and right sides of the inner wall of the main box frame 1 are evenly provided with fixed bayonets, and the central part of the inner wall of the main box frame 1 is evenly provided with a centrifugal rotating device 3 through the fixed bayonet.

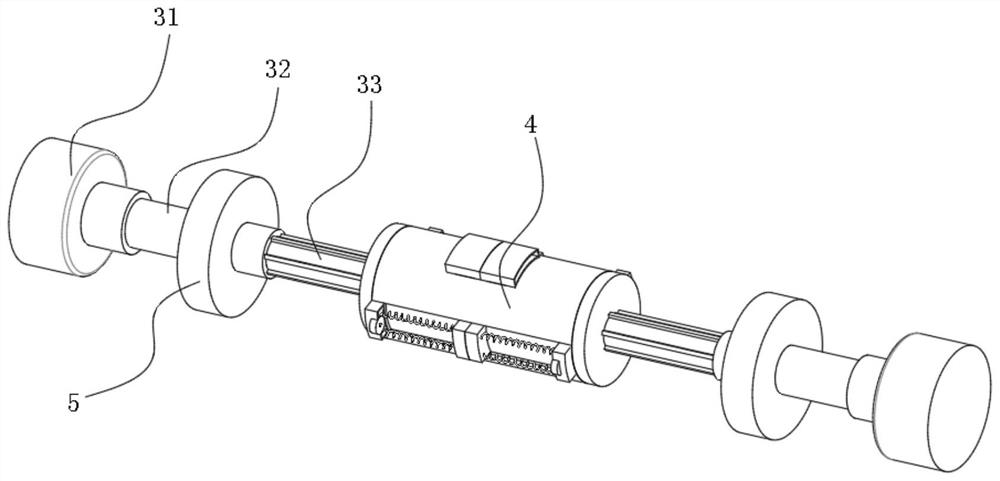

[0035] The centrifugal rotating device 3 includes a fixed motor 31 , the output shaft of the fixed motor 31 is fixedly connected with a hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com