High-impact long-acting yellowing-resistant PBT (polybutylene terephthalate) reinforced flame-retardant composite material as well as preparation method and application thereof

A flame-retardant composite material and anti-yellowing technology, which is applied in the field of engineering plastics to achieve the effect of reducing degradation or qualitative change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

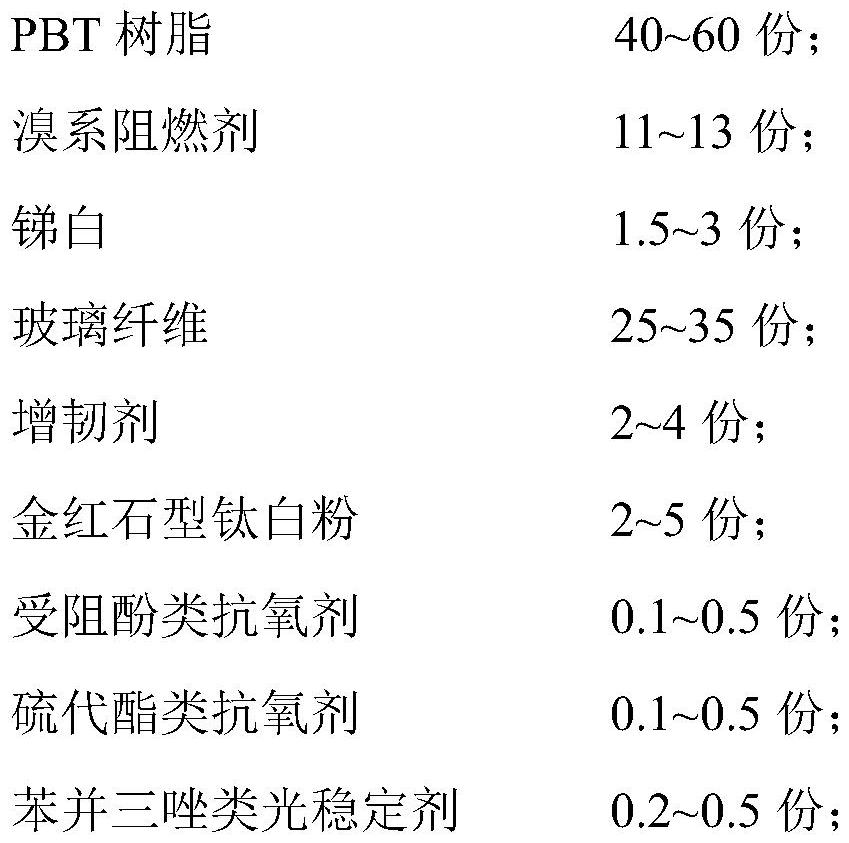

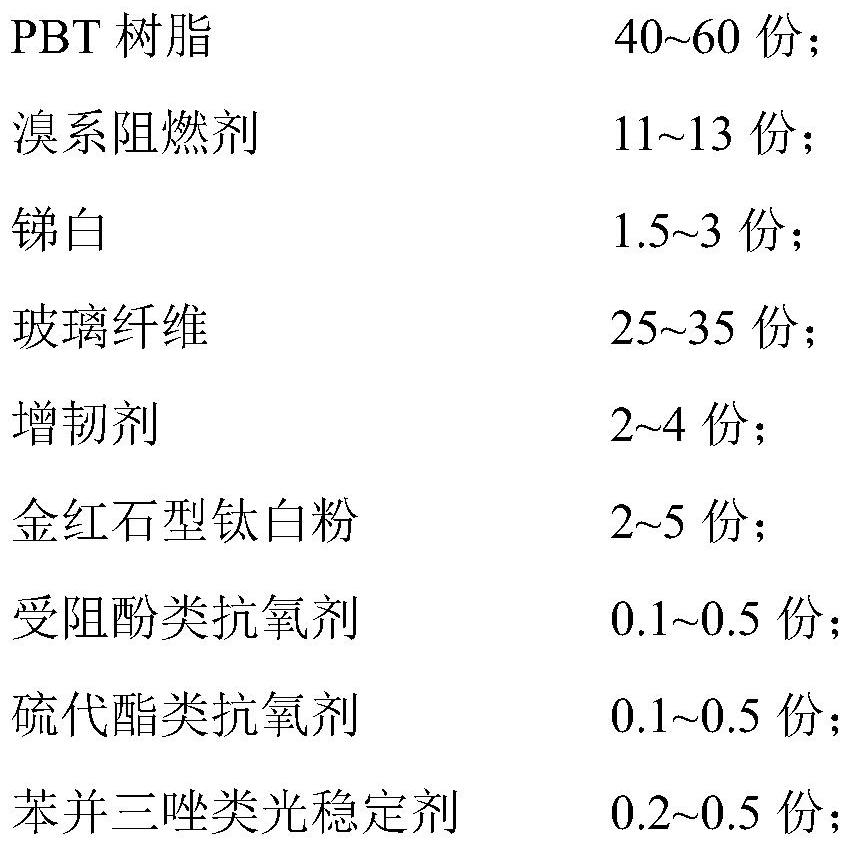

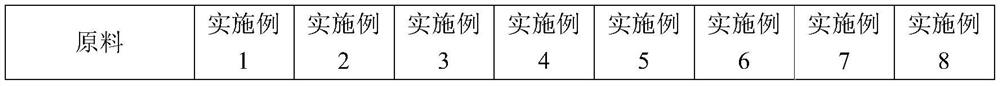

[0057] This example provides a series of PBT reinforced flame retardant composite materials with high impact and long-term yellowing resistance, which are prepared according to the formulas in Tables 1-2 and according to the preparation method including the following steps:

[0058] S1.PBT resin was dried at 120℃ for 4h;

[0059] S2. According to the formula in Tables 1-2, the dried PBT resin, brominated flame retardant, antimony white, glass fiber, toughening agent, rutile titanium dioxide, hindered phenolic antioxidant, thiocyanate The ester antioxidant and the benzotriazole light stabilizer are added to the high-speed mixer, and mixed for 10 minutes at a speed of 300-600 rpm to obtain a uniformly mixed mixed raw material;

[0060] S3. Add the mixed raw material obtained in S2. into the twin-screw extruder from the main feeding port, and add the glass fiber into the twin-screw extruder from the side feeding port. In the twin-screw extruder, the temperature of the screw From...

Embodiment 1

[0097] The results of Example 1, Example 9 and Comparative Example 5 show that the particle size of rutile-type titanium dioxide has a great influence on the performance of the material. In Comparative Example 5, rutile titanium dioxide with larger particle size was selected, and the impact strength of the material decreased significantly.

[0098] The results of Example 1 and Examples 10-13 show that the combination of the antioxidants of the present invention has a certain influence on the performance.

[0099] The results of Comparative Examples 1-3 and 8-9 show that there is a synergistic effect between rutile titanium dioxide, hindered phenolic antioxidants, thioester antioxidants and benzotriazole light stabilizers.

[0100] The results of Comparative Examples 4, 6-7, and Comparative Example 10 show that the combination of specific types of titanium dioxide, antioxidants and light stabilizers selected in the present invention can play a synergistic effect, making the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com