High-transparency ultraviolet light barrier polyester material and preparation method thereof

A polyester material and ultraviolet light technology, applied in the field of polyester materials, can solve the problems of affecting material transmittance, poor thermal stability, temperature sensitivity, etc., to reduce the risk of yellowing, avoid the risk of precipitation, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

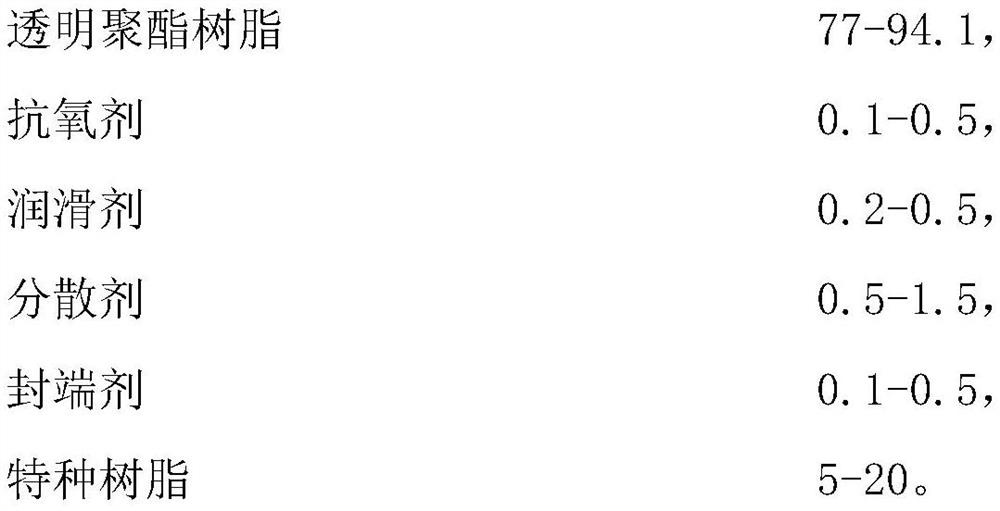

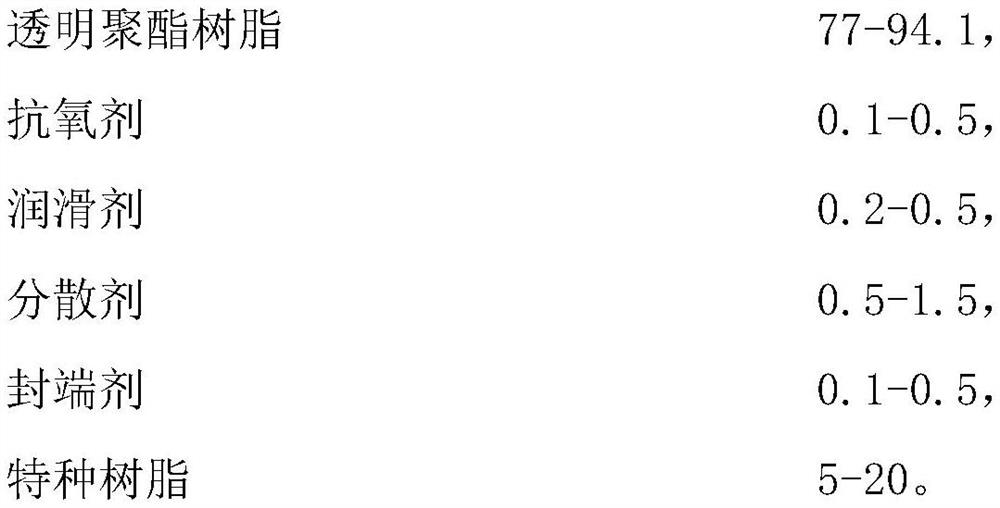

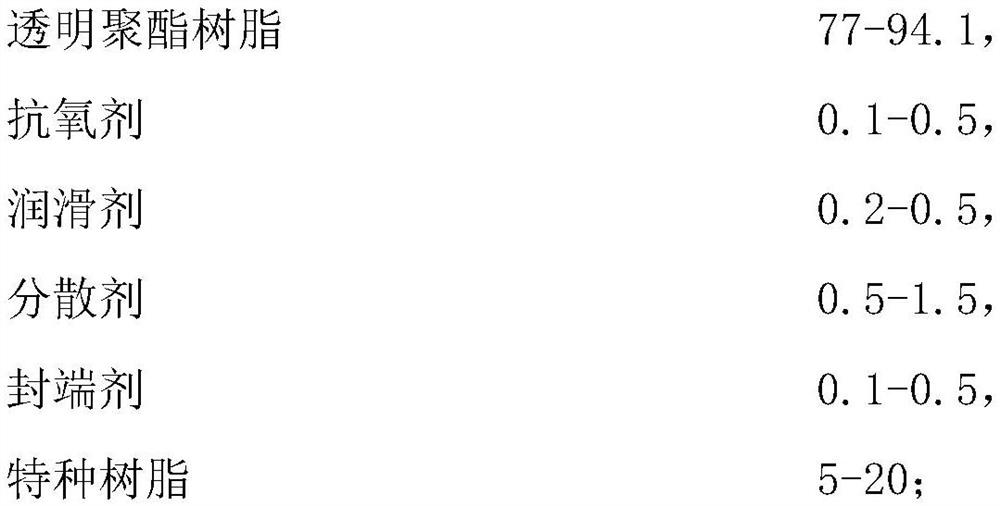

[0028] This example relates to a preparation method of a highly transparent ultraviolet light blocking polyester material. The composition of the polyester material is shown in Table 1. The preparation method includes the following steps:

[0029] (1) Prepare materials according to the components and parts by weight shown in Table 1:

[0030] Among them, the PETG resin is GN046 with a CHDM content of less than 50% from Eastman Company; the antioxidant is Irganox168; the lubricant is pentaerythritol stearate; the dispersant is C100 from Wuhan Hyperbranched Company; The multi-functional resin, the grade is LP2500; the special resin is PEN of Japan Teijin Company;

[0031] (2) Put the PETG resin, antioxidant, lubricant, dispersant, end-capping agent and PEN resin in the above (1) into a high-speed mixer according to the formula and stir them. In the machine, the temperature of the twin-screw extruder is controlled at 240-260°C. Under the conveying, shearing and mixing of the scr...

Embodiment 2

[0033] This example relates to a preparation method of a highly transparent ultraviolet light blocking polyester material. The composition of the polyester material is shown in Table 1. The preparation method includes the following steps:

[0034] (1) Prepare materials according to the components and parts by weight shown in Table 1:

[0035] Among them, the PETG resin is GN046 with a CHDM content of less than 50% from Eastman Company; the antioxidant is Irganox168; the lubricant is pentaerythritol stearate; the dispersant is C100 from Wuhan Hyperbranched Company; The multi-functional resin, the grade is LP2500; the special resin is PEN of Japan Teijin Company;

[0036] (2) Put the PETG resin, antioxidant, lubricant, dispersant, end-capping agent and PEN resin in the above (1) into a high-speed mixer according to the formula and stir them. In the machine, the temperature of the twin-screw extruder is controlled at 250-270°C. Under the conveying, shearing and mixing of the scr...

Embodiment 3

[0038] This example relates to a preparation method of a highly transparent ultraviolet light blocking polyester material. The composition of the polyester material is shown in Table 1. The preparation method includes the following steps:

[0039] (1) Prepare materials according to the components and parts by weight shown in Table 1:

[0040] Among them, the PETG resin is GN046 with a CHDM content of less than 50% from Eastman Company; the antioxidant is Irganox168; the lubricant is pentaerythritol stearate; the dispersant is C100 from Wuhan Hyperbranched Company; The multi-functional resin, the grade is LP2500; the special resin is PEI of Sabic Company in Japan;

[0041](2) Put the PETG resin, antioxidant, lubricant, dispersant, end-capping agent and PEI resin in the above (1) into a high-speed mixer according to the formula and stir, and after mixing evenly, send it to the twin-screw extrusion In the machine, the temperature of the twin-screw extruder is controlled at 240-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com