A kind of decorative mortar and its application

A decorative mortar and sintered sand technology, applied in the field of architectural coatings, can solve the problems of decorative mortar fading, easy back to alkali, small toner particles, etc., to reduce the probability of back alkali, improve anti back alkali, and improve weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

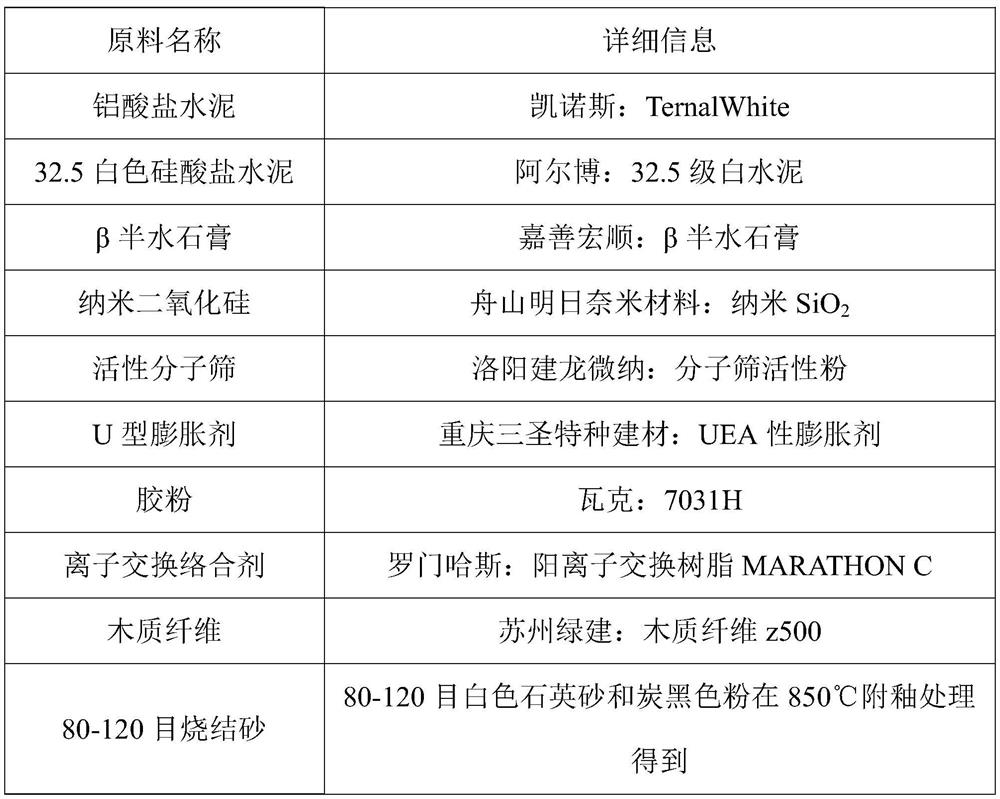

Method used

Image

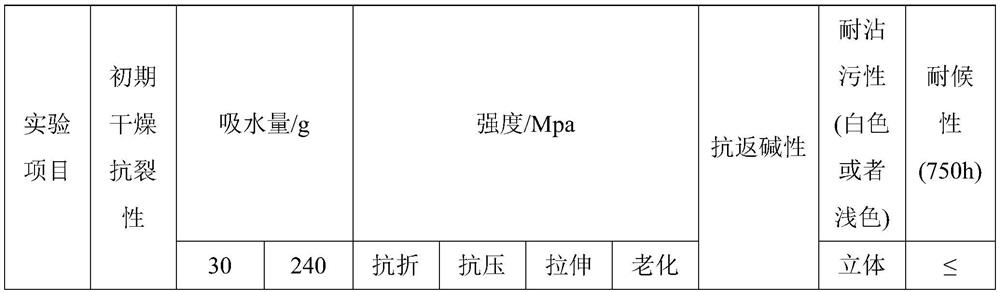

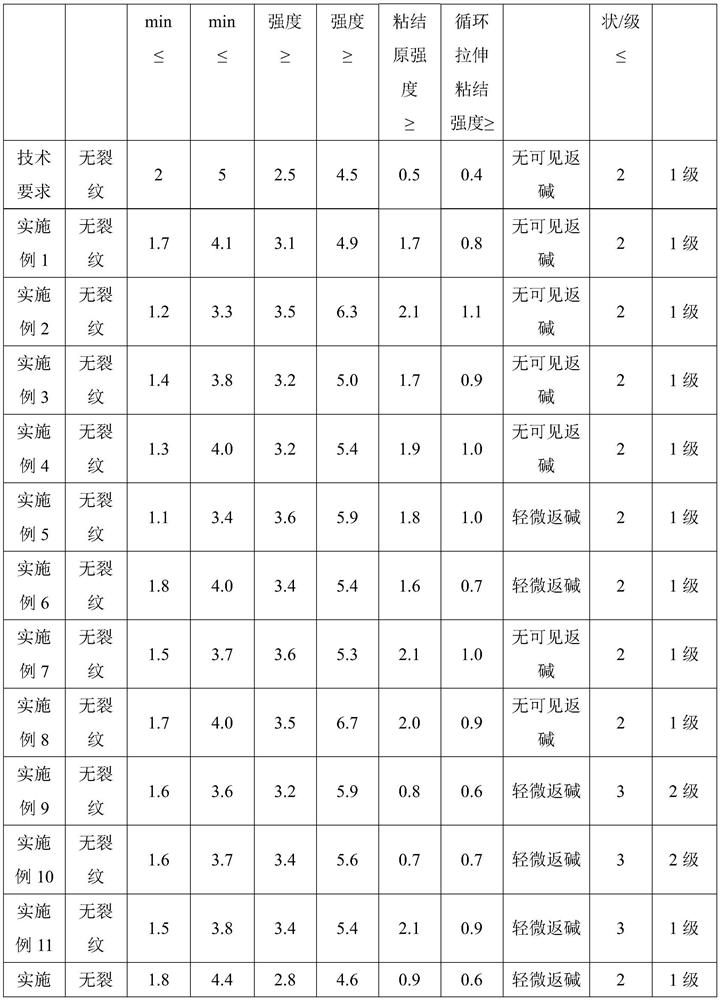

Examples

Embodiment 1

[0076] This embodiment provides a decorative mortar, which includes the following components in parts by weight: 15 parts of aluminate cement, 10 parts of 32.5 white Portland cement, 8 parts of beta hemihydrate gypsum, and 8 parts of active micro-controlling powder. parts (the weight ratio of each composition of the active micro-control powder is: 1250 mesh metakaolin: nano-silica: active molecular sieve: U-type expansion agent = 50:30:10:10), 4 parts of hydrophobic styrene acrylate copolymer, 0.4 part of primary amino acrylate, 0.2 part of hydroxyethyl methyl cellulose ether, 0.2 part of tartaric acid, 0.6 part of wood fiber, 42 parts of 80-120 mesh sintered sand (80 mesh white quartz sand with a weight ratio of 100:2 and Carbon black powder was obtained by glaze treatment at 850°C).

[0077] The preparation method of above-mentioned active micro-control powder is as follows:

[0078] Put 50 parts by weight of metakaolin, 30 parts by weight of nano-silica, 10 parts by weight...

Embodiment 2

[0083] This embodiment provides a decorative mortar, which includes the following components in parts by weight: 18 parts of aluminate cement, 13 parts of 32.5 white Portland cement, 10 parts of beta hemihydrate gypsum, and 10 parts of active micro-control powder (The weight ratio of each composition of the active micro-control powder is: 1250 mesh metakaolin: nano-silica: active molecular sieve: U-shaped expansion agent = 50:30:10:10), 5 parts of vinyl acetate and higher fatty acid vinyl ester copolymer , 0.5 part of quaternary ammonium acrylate, 0.3 part of hydroxyethyl methyl cellulose ether, 0.3 part of tartaric acid, 0.8 part of wood fiber, 54 parts of 80-120 mesh sintered sand (120 mesh white quartz sand and charcoal with a weight ratio of 100:2 The black powder was obtained by glazing at 850°C).

[0084] The preparation method of above-mentioned active micro-control powder is as follows:

[0085] Put 50 parts by weight of metakaolin, 30 parts by weight of nano-silica, ...

Embodiment 3

[0090] This embodiment provides a decorative mortar, which includes the following components in parts by weight: 16 parts of aluminate cement, 11 parts of 42.5 white Portland cement, 9 parts of beta hemihydrate gypsum, and 9 parts of active micro-control powder parts (the weight ratio of each composition of the active micro-control powder is: 800 mesh metakaolin: nano-silicon dioxide: active molecular sieve: U-type expansion agent = 50:30:10:10), vinyl acetate and ethylene and higher fatty acid vinyl ester three 4.5 parts of metacopolymer, 0.45 part of primary amino acrylate, 0.25 part of methyl cellulose ether, 0.25 part of citric acid, 0.7 part of glass fiber, 48 parts of 80-120 mesh sintered sand (100 mesh with a weight ratio of 100:2 White quartz sand and carbon black powder were obtained by glaze treatment at 800 °C).

[0091] The preparation method of above-mentioned active micro-control powder is as follows:

[0092] Put 50 parts by weight of metakaolin, 30 parts by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com